Voice-coil-motor-driven high-speed switch valve

A high-speed switching valve, voice coil motor technology, applied in valve details, valve devices, mechanical equipment, etc., can solve the problems of slow switching speed, small flow rate of single-stage valve, etc., to avoid leakage, improve sealing reliability, and improve the system. The effect of controlling precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

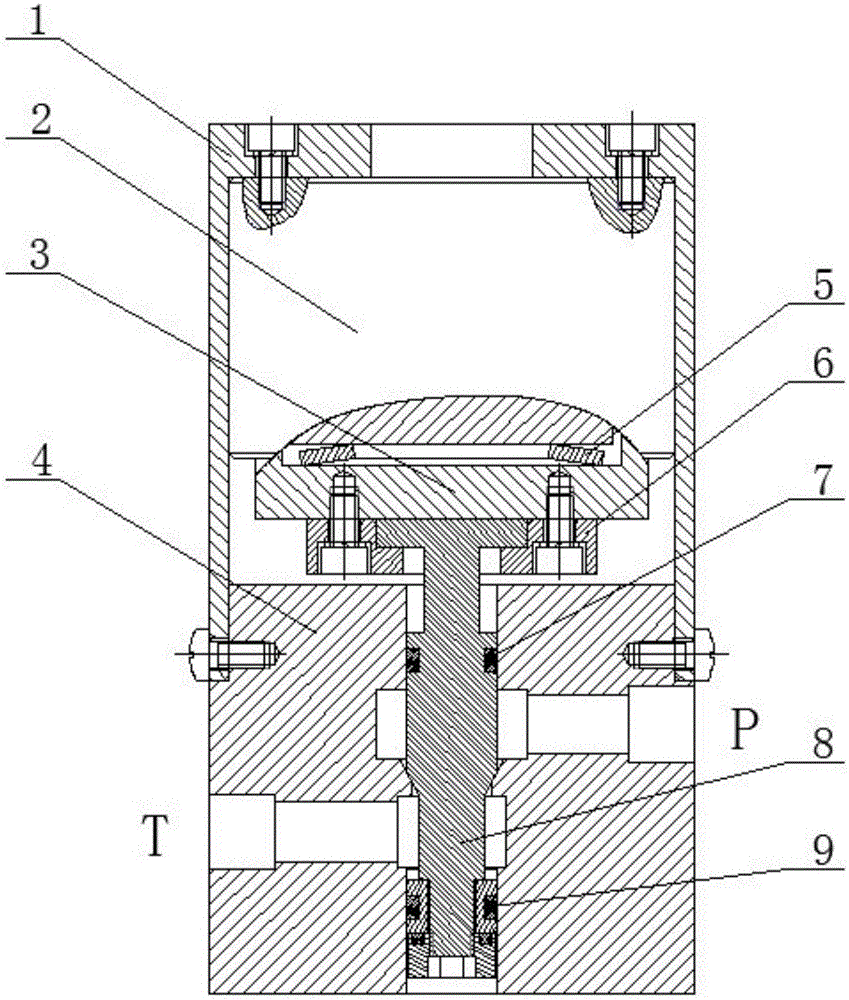

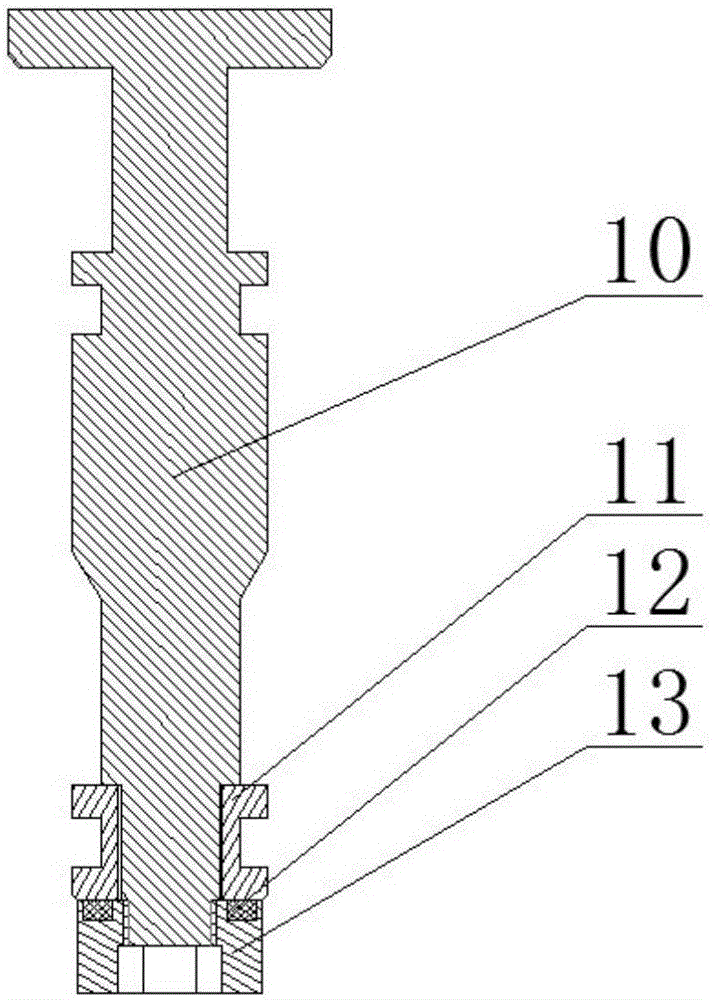

[0016] like Figure 1 to Figure 3 As shown, an embodiment of the present invention includes: motor fixing bracket 1, motor stator 2, motor mover 3, valve body 4, disc spring 5, gland 6, dynamic seal 1 7, valve core 8, dynamic seal 2 9 , Cone spool 10, compensation sealing piston 11, end face seal 12, inner hex nut 13, etc.

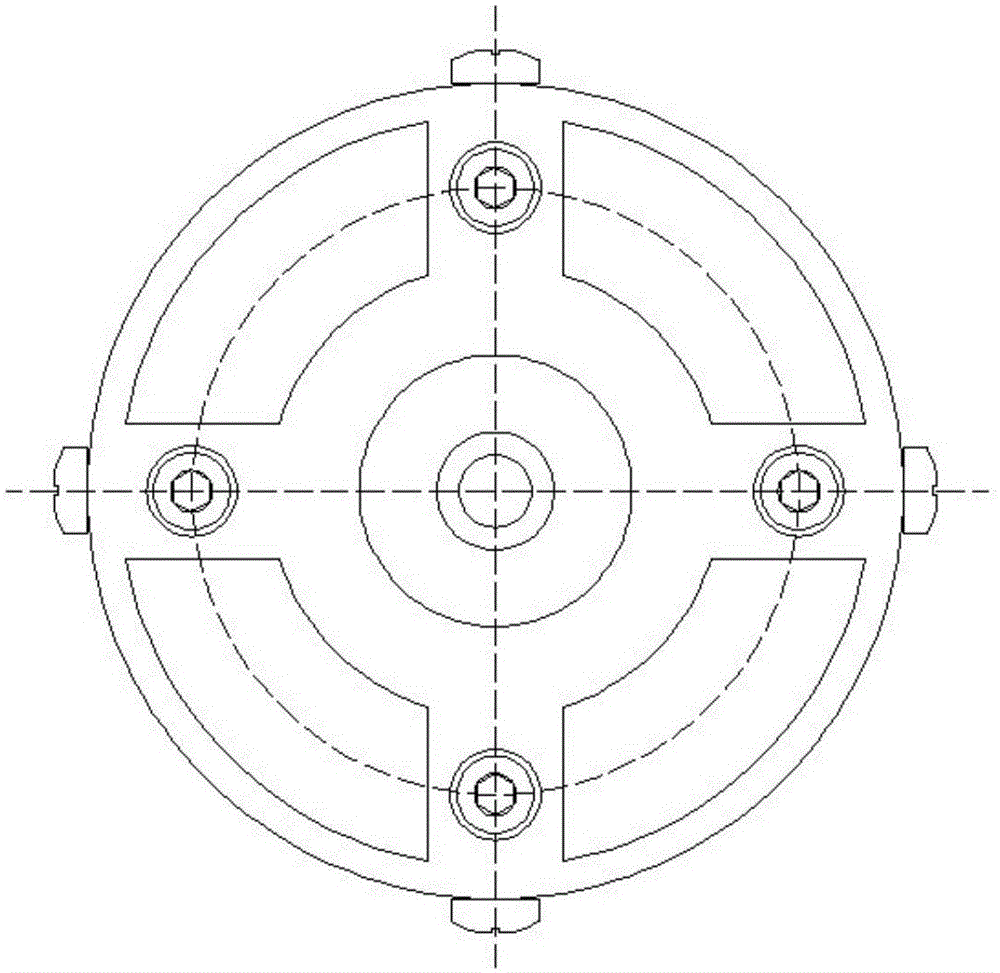

[0017] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a top view of the structure of the present invention. Among them, the stator 2 of the voice coil motor is kept fixed relative to the on-off valve, and the mover of the motor 3 is directly connected and fixed with the spool 8 of the on-off valve. ; When the voice coil motor passes the reverse current, the motor mover 3 drives the switch valve spool 8 to move upward against the dynamic friction force and the spring force, and the valve port opens; when the voice coil motor passes the forward current, the motor mover 3 drives the switch The valve core 8 moves do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com