Multifunctional longitudinal movement driving device for bridge girder erection machine

A technology of a driving device and a bridge erecting machine, which is applied in the direction of erecting/assembling bridges, bridges, walking mechanisms, etc., can solve the problems of difficulty in arranging via-hole walking driving mechanisms, difficult layout of wheel driving mechanisms, and difficulty in providing driving force, etc. The effect of compactness, high driving force and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

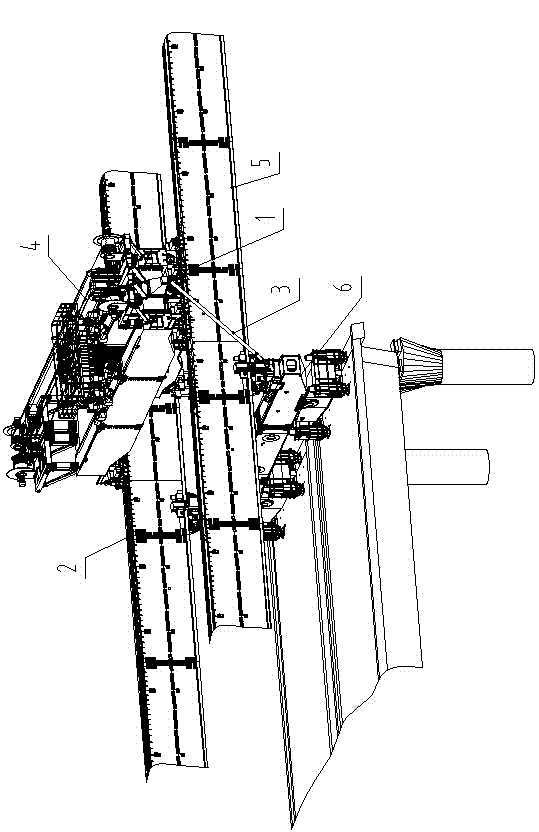

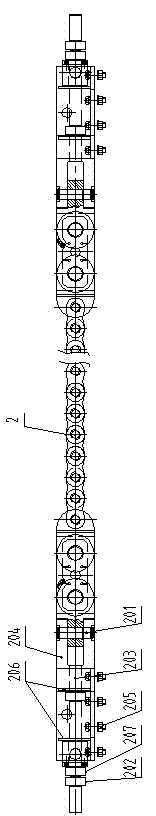

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the multifunctional longitudinal movement drive device for a bridge erecting machine of the present invention includes a drive module 1 arranged on the bridge erecting machine crane 4, a drive chain 2 on the bridge erecting machine main girder 5, and a bridge erecting machine crane 4 and the strut mechanism 3 between the main legs 6.

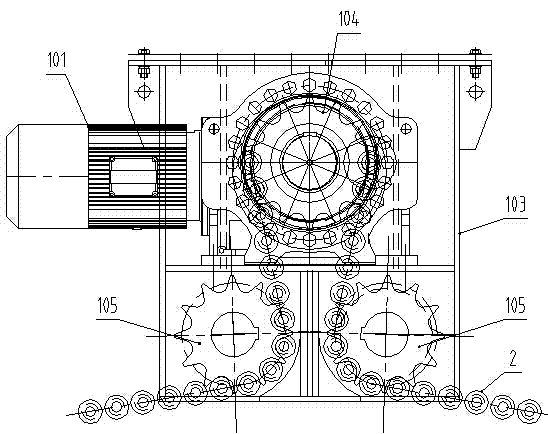

[0022] Drive module 1 comprises drive casing 103, reduction motor 101, drive sprocket 104 and two driven sprockets 105, reduction motor 101 is located on the drive casing 103, and drive sprocket 104 and two driven sprockets 105 are set In the drive box 103, the power drive end of the reduction motor 101 is connected to the drive sprocket 104 in transmission, and the two driven sprockets 105 are respectively located at the front side and the rear side below the drive sprocket 104, and the front and rear ends of the drive chain 2 are respectively It is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com