Measuring device and measuring method for position of reticle stage of scanning lithography

A technology of measuring device and mask stage, which is applied in the direction of photolithography process exposure device, microlithography exposure equipment, etc. restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

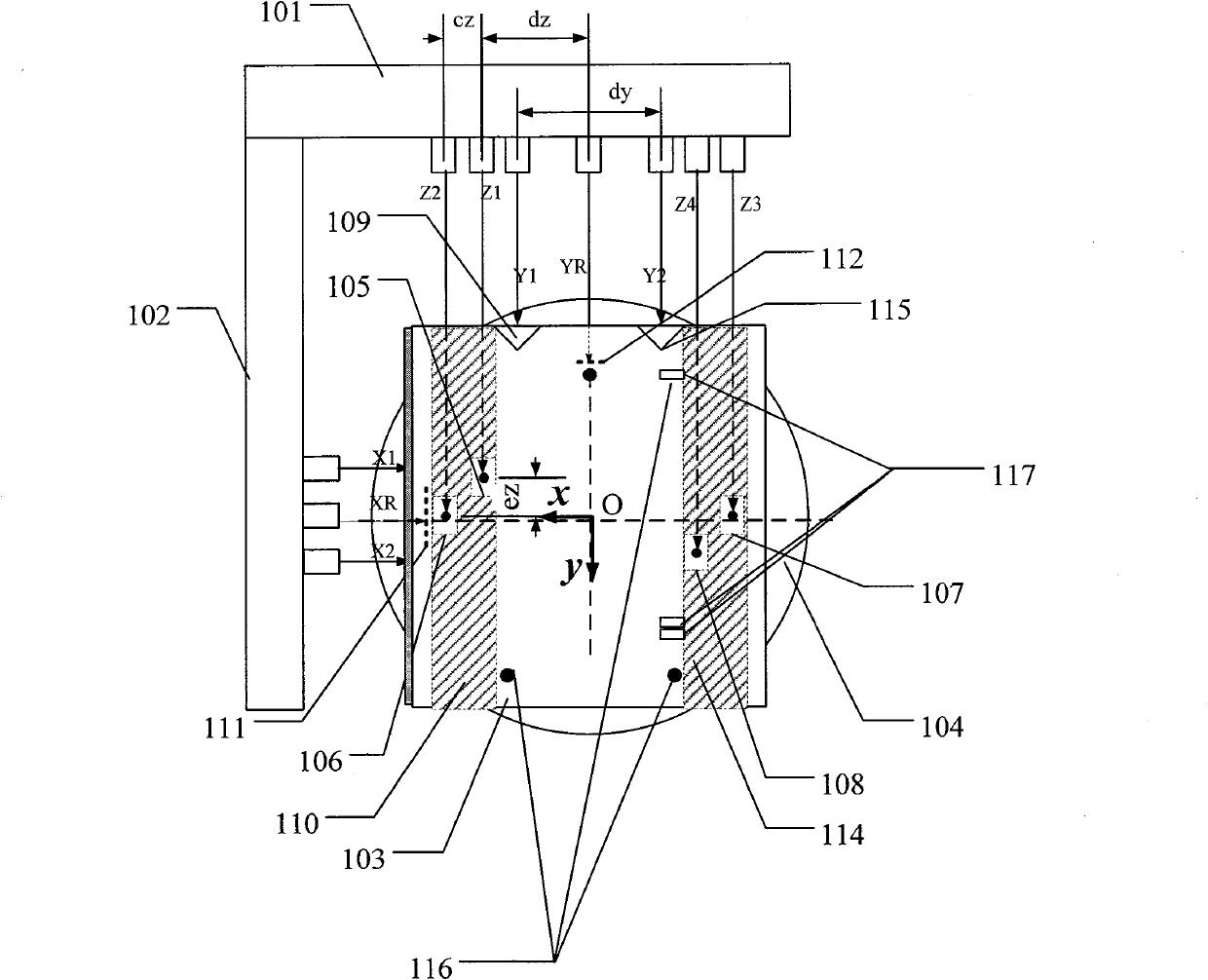

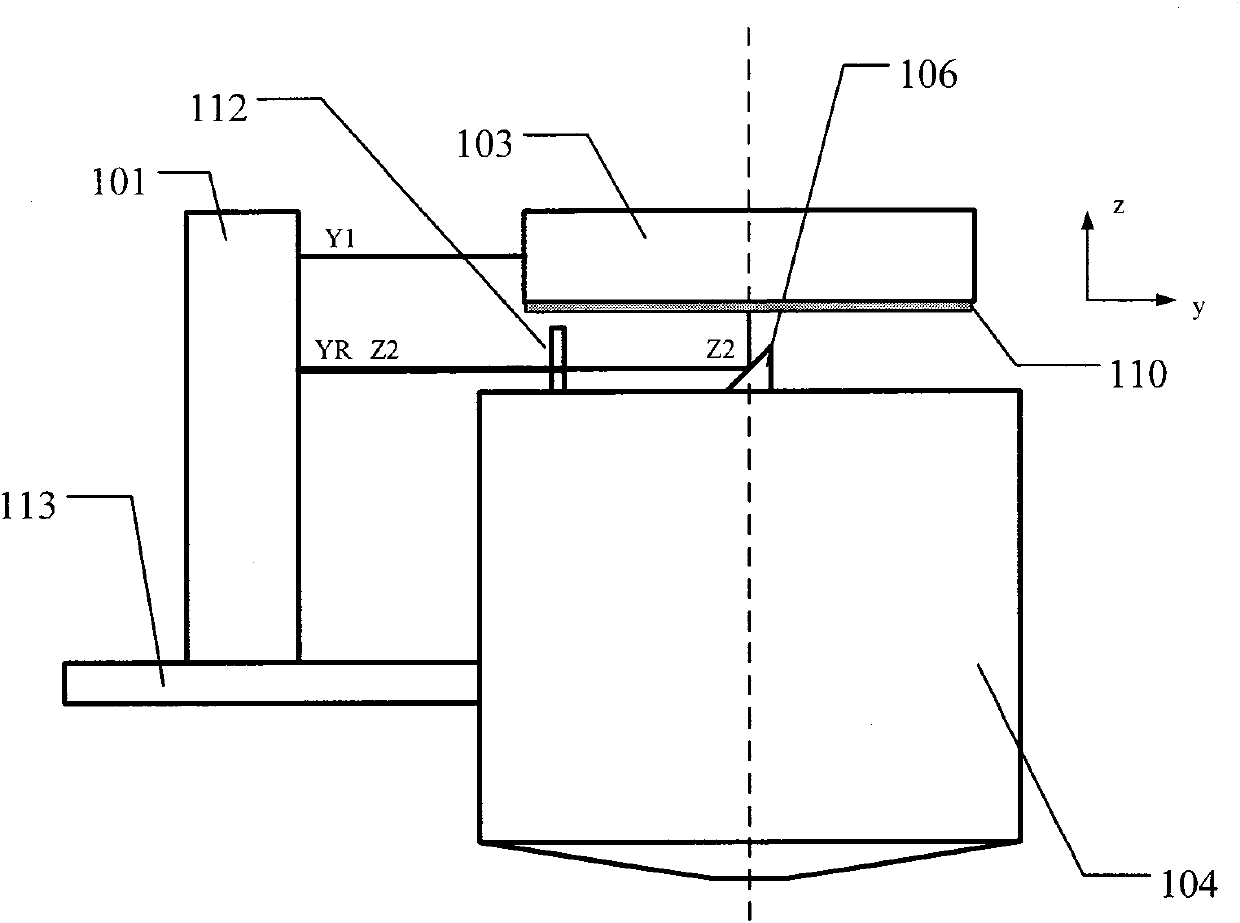

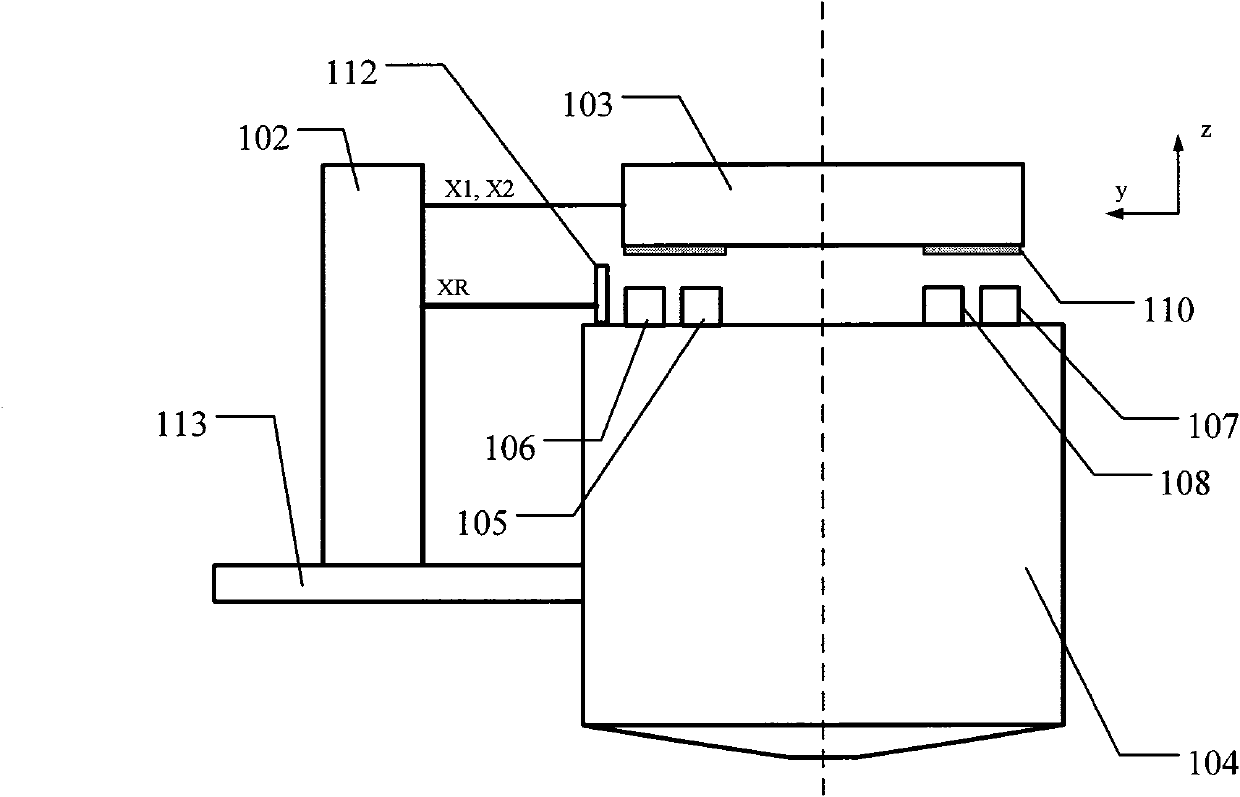

[0021] figure 1 A top view of the mask table position measuring device of the scanning lithography machine provided by the present invention, figure 2 , image 3 respectively figure 1 Left and front views of the mask stage position measuring device of the scanning lithography machine shown.

[0022] Such as Figure 1 ~ Figure 3 As shown, in this specific embodiment, the device for measuring the position of the mask stage of a scanning lithography machine includes: a horizontal longitudinal (y-direction) measurement module 101, a horizontal horizontal (x-direction) measurement module 102, a mask stage 103, an objective lens 104 and main substrate 113 . Wherein, the horizontal longitudinal (y-direction) measurement module 101 and the horizontal transverse (x-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com