A Numerical Control System of Can Printing Machine Based on Digital Motion Controller

A technology of motion controller and numerical control system, applied in the direction of digital control, general control system, control/regulation system, etc., can solve the problems of printing accuracy and printing speed limitation, mechanical long axis fluctuation, difficult installation and maintenance, etc., and achieve simple upgrade , good synchronous control and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

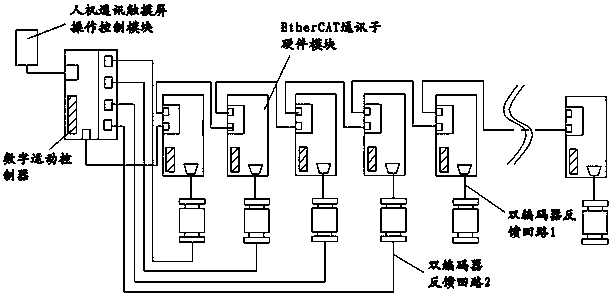

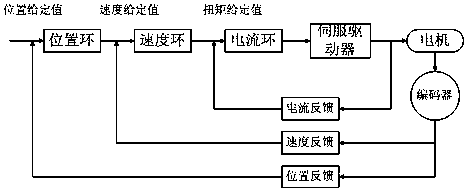

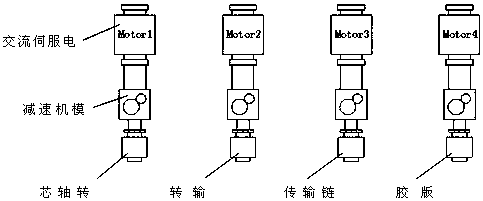

[0036] A numerical control system for can printing machines based on digital motion controllers, such as figure 1 As shown, it includes the man-machine communication touch screen operation control module based on the Windows platform, the digital motion controller, the motion execution module namely the AC servo motor and the reducer module. The man-machine communication touch screen operation control module based on the Windows platform is responsible for the task of managing the entire system, while the digital motion controller is responsible for the intermediary tasks of receiving instructions from the host computer and transmitting them to the motion module and completing data processing and signal determination.

[0037] In the present invention, the man-machine co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com