Method for preparing methanol synthesis gas with oven gas and blast furnace gas

A technology of methanol synthesis gas and blast furnace gas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., and can solve the problems of converter gas pressure and component fluctuations, insufficient methanol production for carbon supplementation, low CO content and calorific value, etc. Achieve the effects of low impurity gas content, low cost, and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

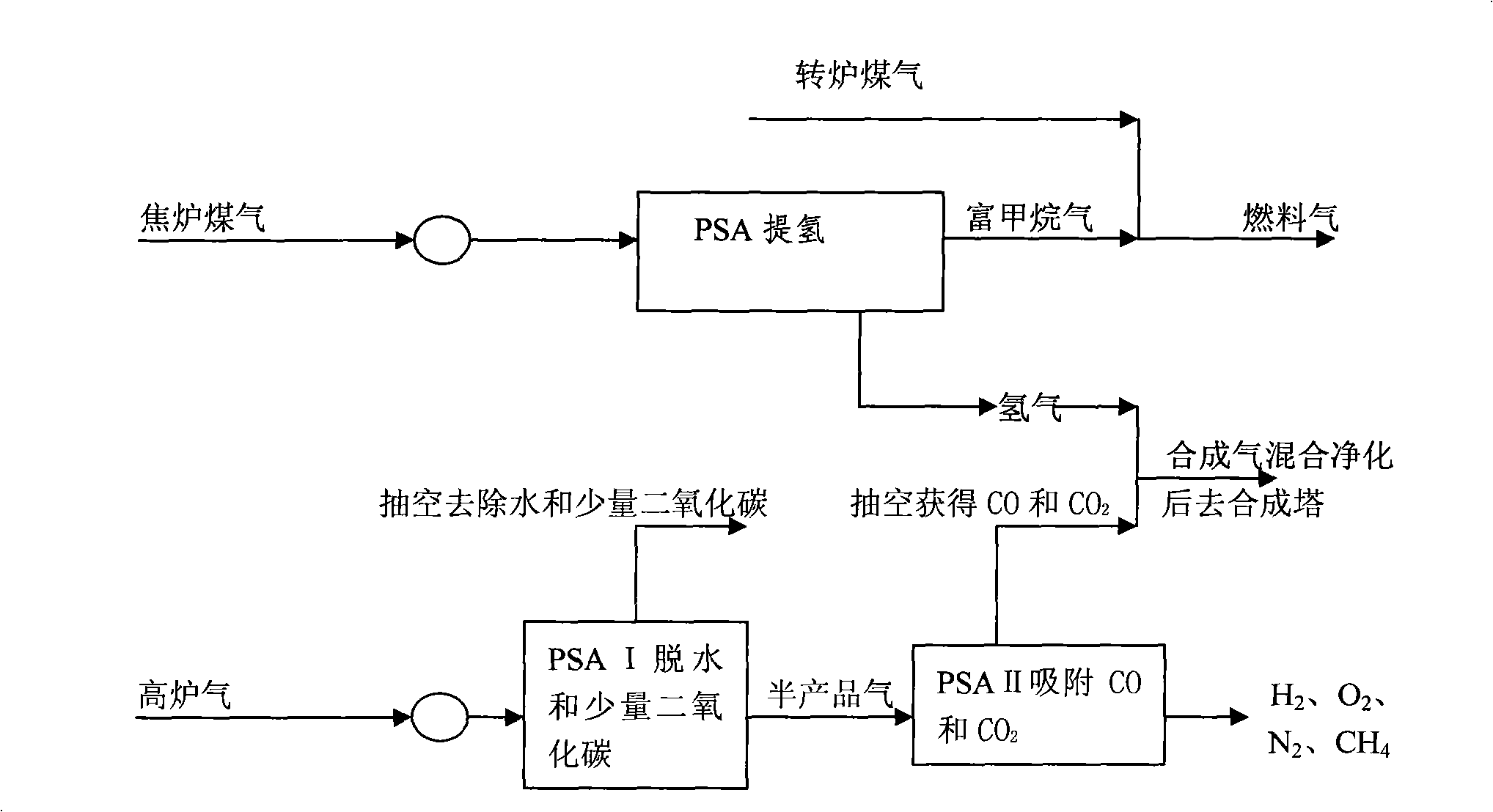

[0022] figure 1 Schematic diagram of the process flow for preparing methanol mixed gas by pressure swing adsorption of coke oven gas and blast furnace gas.

[0023] (1) Using coke oven gas as raw material, extract H by pressure swing adsorption method 2 :

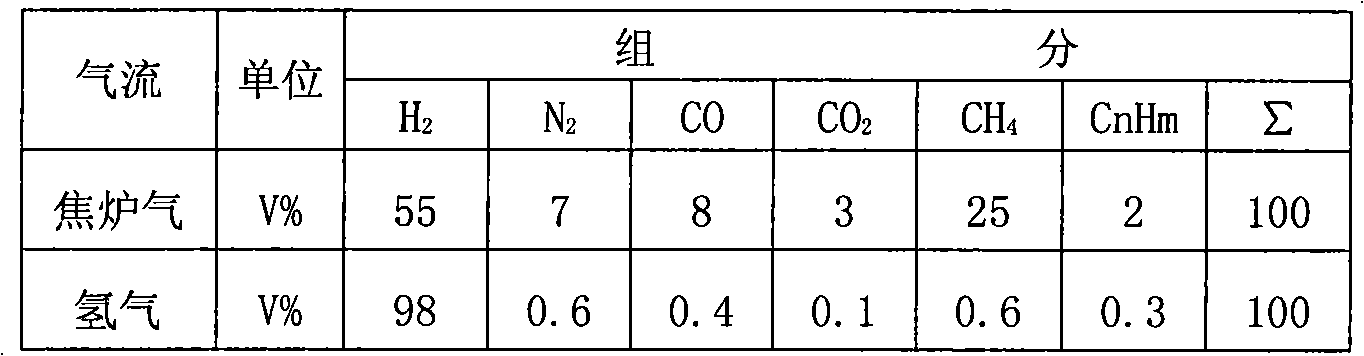

[0024] Raw coke oven gas flow rate 5500Nm 3 / h, the composition is shown in Table 1, it is compressed to a pressure range of 0.1-1.0 MPa, and then it is separated into hydrogen and methane-rich fuel gas in a pressure swing adsorption hydrogen extraction device.

[0025] Table 1 Coke oven gas pressure swing adsorption hydrogen extraction feed gas and product gas composition

[0026]

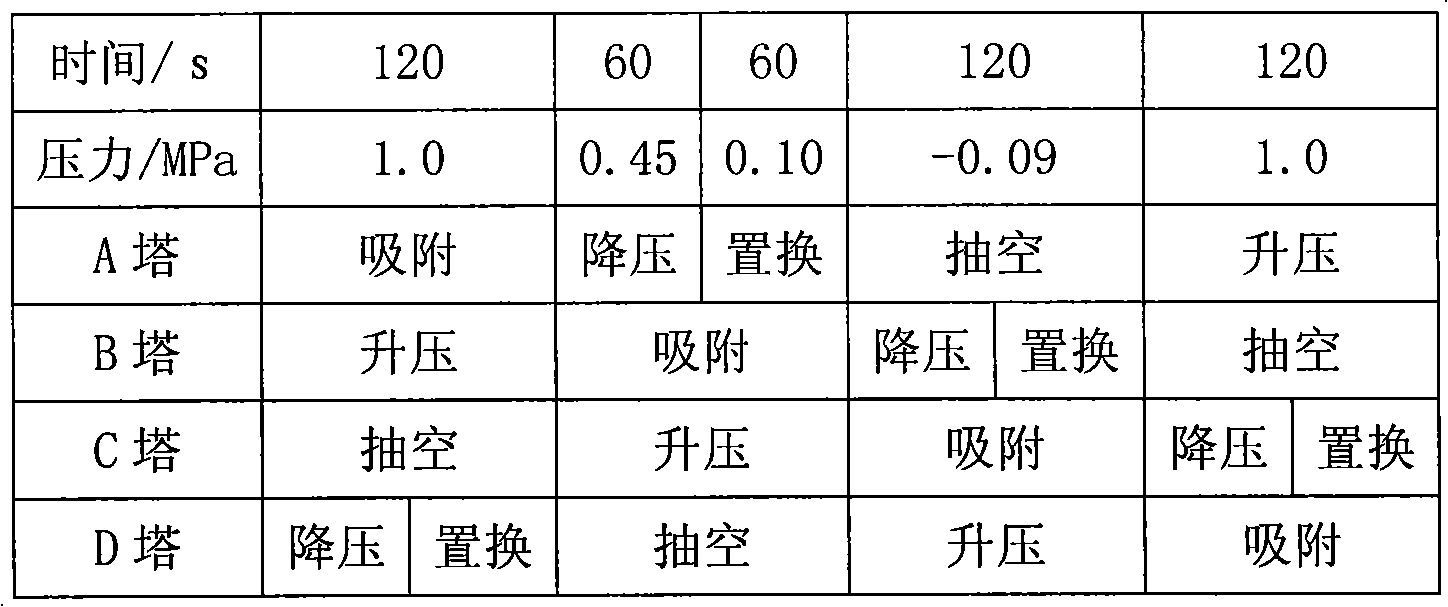

[0027] The coke oven gas pressure swing adsorption hydrogen extraction device in this embodiment is composed of 4 adsorption towers, and the towers are connected by corresponding pipelines and program-controlled valves. Each adsorption tower is filled with adsorbent activated alumina, Activated carbon, the height ratio of the filling is ...

Embodiment 2

[0043] (1) Using coke oven gas as raw material, extract H by pressure swing adsorption method 2 :

[0044] Raw coke oven gas flow rate 45000Nm 3 / h, the composition is shown in Table 6, it is compressed to a pressure range of 0.1-1.0MPa, and then H is extracted in a pressure swing adsorption hydrogen extraction device 2 . The coke oven gas pressure swing adsorption hydrogen extraction device in this embodiment is composed of 8 adsorption towers, and the towers are connected by corresponding pipelines and program-controlled valves. Each adsorption tower is filled with adsorbent silica gel and activated carbon from top to bottom. The filling height ratio is silica gel: activated carbon = 1:3; coke oven gas enters two adsorption towers for adsorption at the same time, and each adsorption tower undergoes adsorption A sequentially in one cycle, and the four average pressure drops E1D, E2D, E3D, E4D , put PP in forward direction, put D in reverse, wash P, four times of pressure e...

Embodiment 3

[0061] (1) Using coke oven gas as raw material, extract H by pressure swing adsorption method 2 :

[0062] Raw coke oven gas flow rate 93000Nm 3 / h, the composition is shown in Table 11, it is compressed to a pressure range of 0.2-2.0MPa, and then H is extracted in a pressure swing adsorption hydrogen extraction device 2 . In this embodiment, the coke oven gas pressure swing adsorption hydrogen extraction device is composed of 10 adsorption towers, and each adsorption tower is filled with adsorbent activated alumina and molecular sieve from top to bottom, and the height ratio of the filling is activated alumina:molecular sieve=1 : 5; coke oven gas enters three adsorption towers for adsorption at the same time, and each adsorption tower undergoes adsorption A, pressure equalization drop ED, parallel discharge PP, reverse discharge D, flushing P, pressure equalization rise ER, and finally In the pressure swing adsorption process of pressure equalization FR, the adsorption pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com