Conversion of coke oven gas carbon dioxide and gas-based shaft kiln directly reduced iron production method

A technology for coke oven gas and carbon dioxide, which is applied in the fields of combustible gas purification, combustible gas purification/transformation, petroleum industry, etc. Direct reduction requirement, effect of increasing CO content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

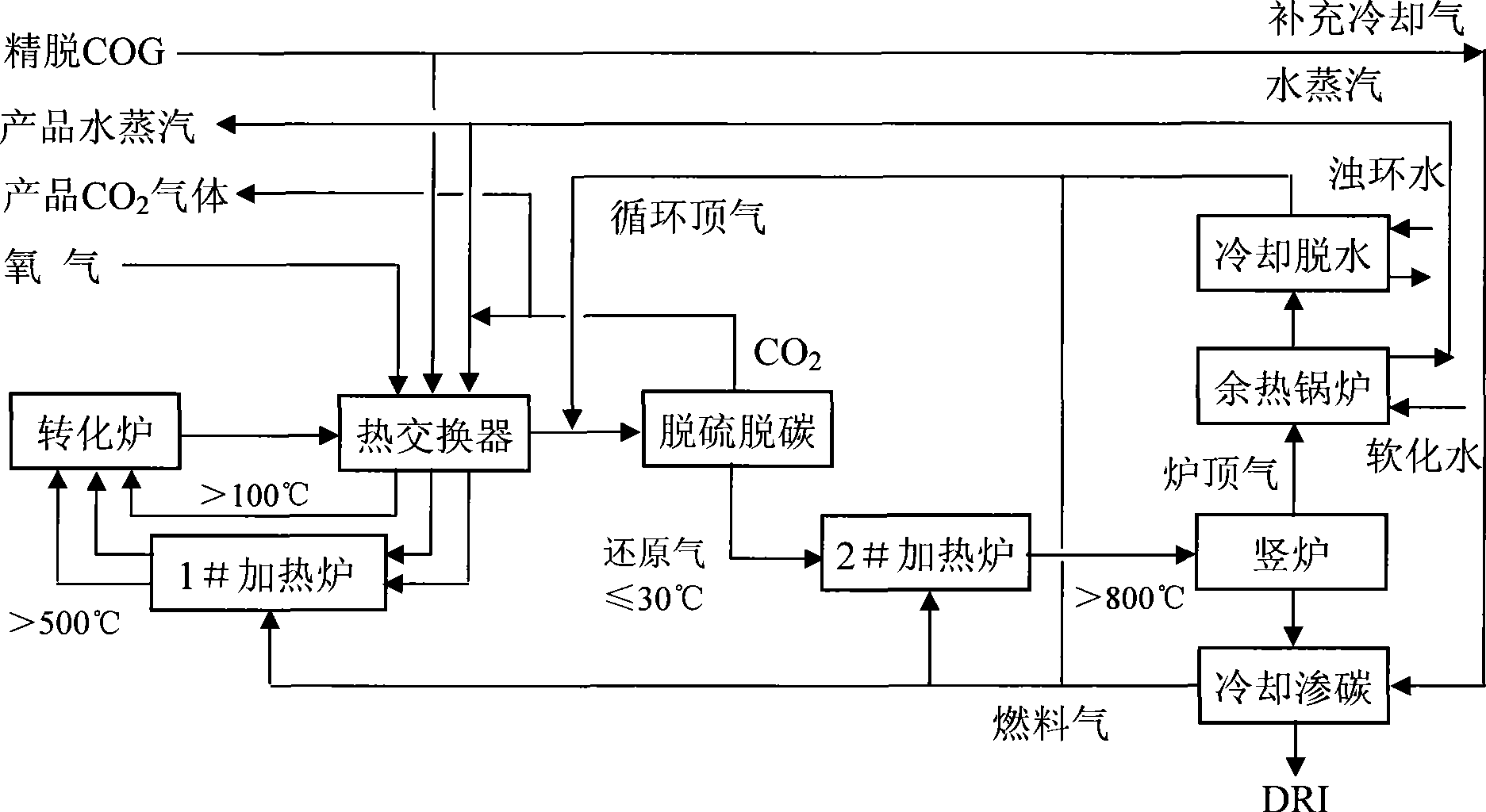

[0020] Gas-based shaft furnace direct reduction iron production method of the present invention, its preferred embodiment, comprises steps:

[0021] The reformed gas produced by the above coke oven gas carbon dioxide conversion method is used as the reducing gas produced by the gas-based shaft furnace direct reduction iron production method; the fuel gas heated by the coke oven gas and the conversion agent can be used by the gas-based shaft furnace direct reduction iron production method top gas.

[0022] The other part of the furnace top gas in the gas-based shaft furnace direct reduction iron production method is used as process gas, which is concentrated with the cooled reformed gas for dehydrogenation and decarbonation, and then further cooled to below 30°C to reduce saturated water vapor in the gas content, this mixed gas is the reducing gas, and then the reducing gas is heated to above 800°C, and then enters the shaft furnace to reduce iron oxide minerals to produce dire...

specific Embodiment 1

[0026] Specific embodiment one, see again figure 1 :

[0027] First of all: the coke oven gas used as raw material gas is subjected to advanced purification treatment, including: oil removal, purification and desulfurization treatment, and the sulfur content after treatment is <5PPM;

[0028] Then, use oxygen, carbon dioxide gas, and water vapor as conversion agents for conversion.

[0029] The amount of conversion agent used per mol of purified coke oven gas is: oxygen: ≤0.25 mol; carbon dioxide: ≤0.3 mol; water vapor: ≤0.3 mol.

[0030] Four raw material gases of coke oven gas, oxygen, carbon dioxide and water vapor in the above ratio are heated. Oxygen is heated above 100°C, and other gases are heated above 500°C.

[0031] Then, the heated gas is reformed in a reformer, and the reformed gas produced is used as reducing gas for the gas-based shaft furnace direct reduction iron production process.

[0032] In order to ensure efficient and stable operation of the reduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com