Preparation method of sm-co based amorphous nanocrystalline thin strip magnet

An amorphous nanocrystal, sm-co technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of low hard magnetic properties of alloys, Sm-based amorphous alloy materials have not yet appeared, and no existing High coercive force Sm-Co based amorphous nanocrystalline alloy materials and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

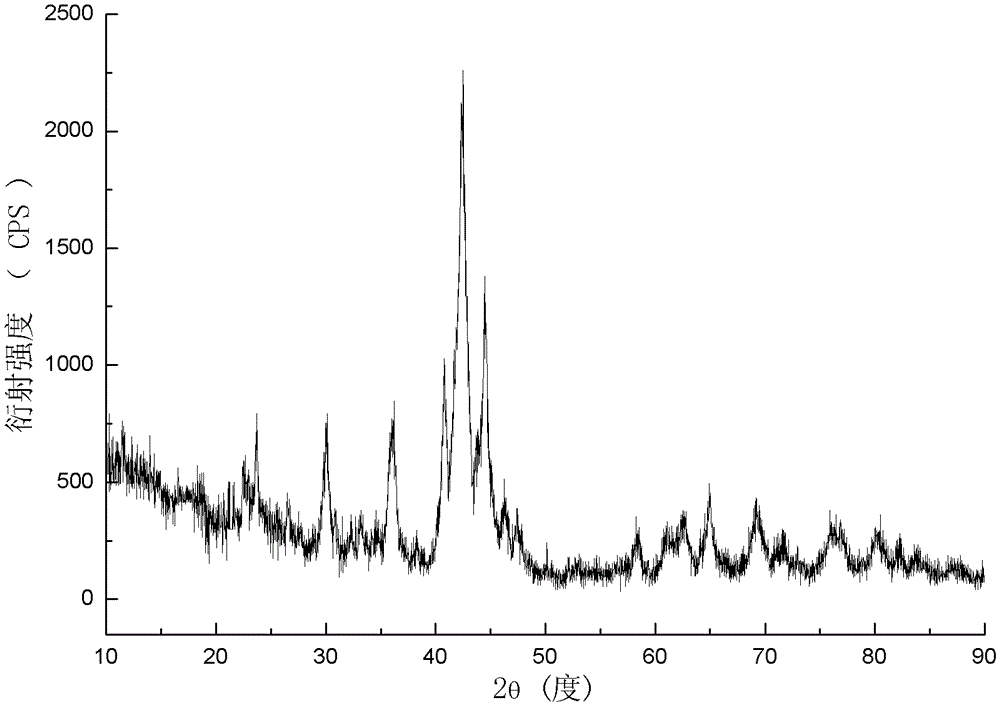

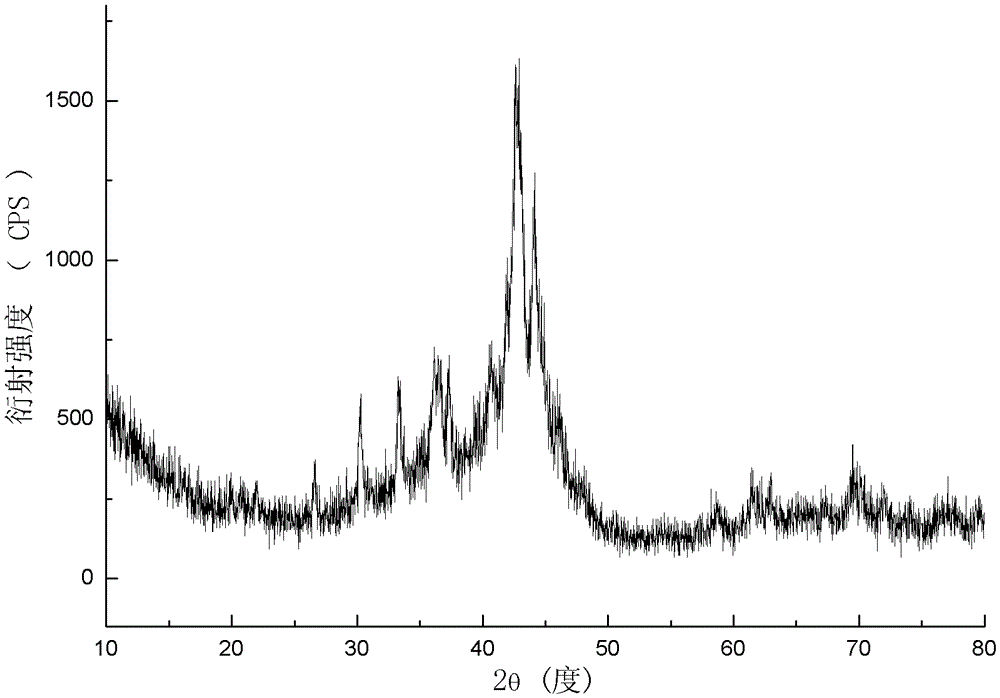

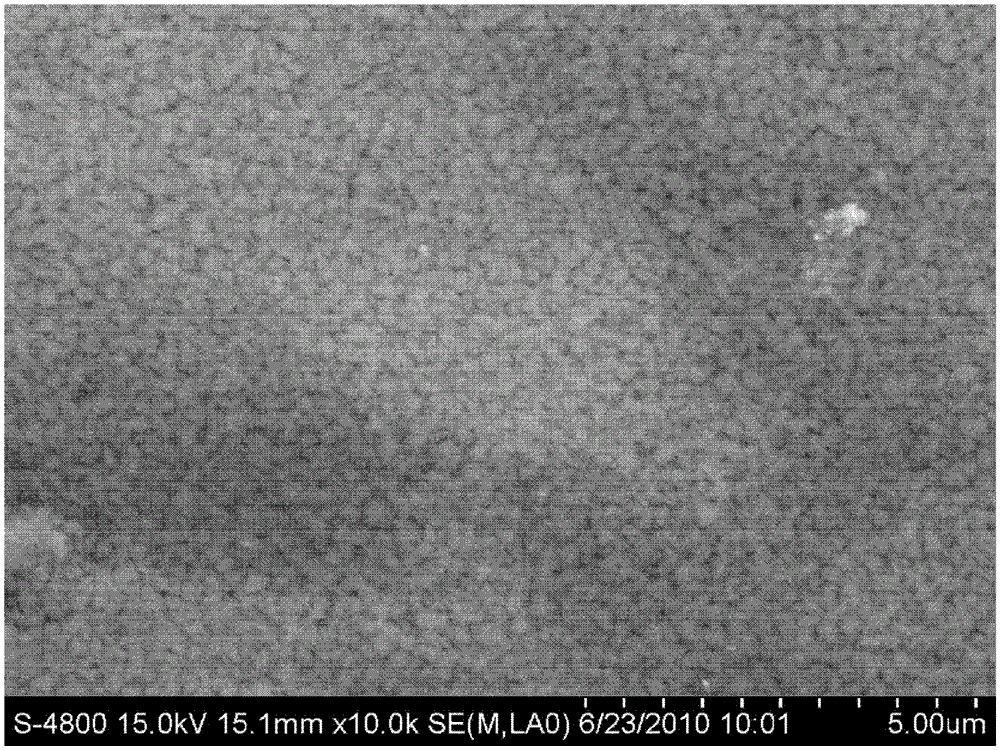

[0043] Sm of Sm-Co-based Amorphous and Nanocrystalline Thin Strip Magnets 11.3 co 56.6 Fe 7.5 Zr 4.7 B 3.8 (Nb 4.7 al 5.7 Si 4.7 C 1.0 ) A preparation method of an amorphous nanocrystalline thin strip magnet.

[0044] The first step, raw material preparation

[0045] According to the raw material ratio Sm in atomic percentage 11.3 co 56.6 Fe 7.5 Zr 4.7 B 3.8 (Nb 4.7 al 5.7 Si 4.7 C 1.0 ), take raw material pure Sm, pure Co, pure Fe, pure Zr, B-Fe alloy, pure Nb, pure Al, pure Si and pure graphite C powder, additionally add the pure The mass percentage of Sm is 3% pure Sm, thus completing the raw material preparation.

[0046] The second step is to melt the raw materials to prepare master alloy ingots

[0047] Put all the raw materials prepared in the first step into the crucible of the vacuum arc melting furnace. When melting, first vacuumize the furnace body to 10 -3 Pa, the temperature of the furnace is raised above the melting point of the raw metal Zr, ...

Embodiment 2

[0052] Except that the peripheral speed of the cooling molybdenum roller wheel rotation of the third step in embodiment 1, that is, the rapid quenching speed of the melt becomes 5m·s -1 Except, others are all the same as embodiment 1, and the prepared Sm 11.3 co 56.6 Fe 7.5 Zr 4.7 B 3.8 (Nb 4.7 al 5.7 Si 4.7 C 1.0 ) The magnetic properties, thickness and average grain size parameters of the main crystal phase of the amorphous and nanocrystalline thin strip magnets are shown in Table 1.

Embodiment 3

[0054] Except the circumferential speed that the cooling molybdenum roll wheel of the third step in the embodiment 1 rotates, the rapid quenching speed of the melt becomes 15m·s -1 Except, others are all the same as embodiment 1, and the prepared Sm 11.3 co 56.6 Fe 7.5 Zr 4.7 B 3.8 (Nb 4.7 al 5.7 Si 4.7 C 1.0 ) The magnetic properties, thickness and average grain size parameters of the main crystal phase of the amorphous and nanocrystalline thin strip magnets are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com