Device and method for direct catalytic cracking or reforming of high-temperature pyrolysis gas of carbon-containing substance

A high-temperature pyrolysis and catalytic cracking technology, which is applied in the direction of combustible gas purification, chemical modification of combustible gas, and heat treatment of combustible gas, can solve the problems of ecological environment threat, complex composition, waste of water resources, etc., and achieve the elimination of investment and Effects of operating costs, shortening the process flow, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

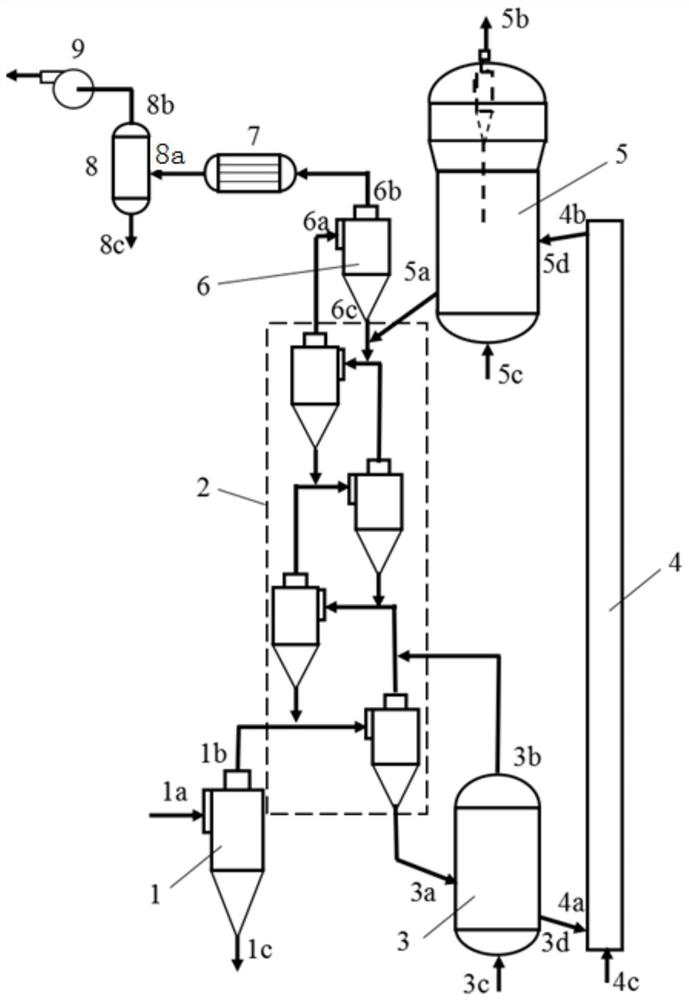

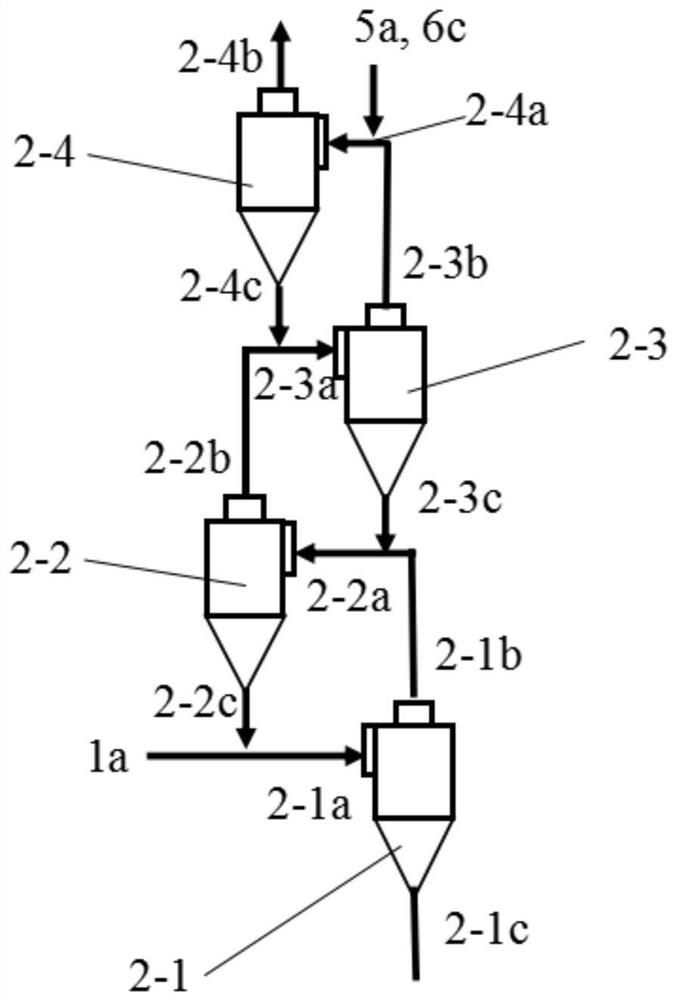

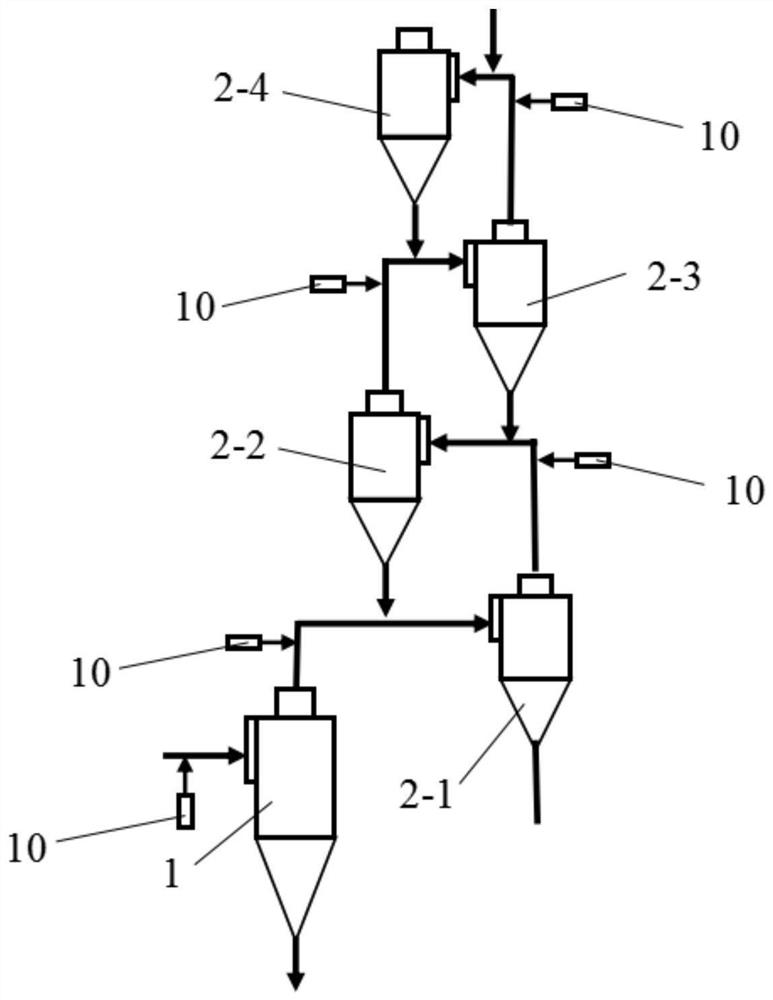

[0061] The device used in this embodiment includes a pyrolysis cyclone separator 1, a multistage tar cracking reactor 2, a catalyst buffer tank 3, a riser carbon oxidation reactor 4, a fluidized bed charcoal regenerator 5, a cyclone dust collector 6, a Heat cooler 7, oil-gas separator 8, induced draft fan 9 and thermostat 10. The multi-stage tar cracking reactor 2 is composed of 4 stages of cyclone contact separators, wherein the form of cyclone contact separators is Humboldt type. The inner diameter of the riser charcoal oxidation reactor 4 is 500mm and the height is 6m; the inner diameter of the lower straight cylinder part of the fluidized bed charcoal regenerator 5 is 2000mm and the height is 8m. The catalyst buffer tank 3 has an inner diameter of 1000 mm and a height of 2 m; the bottom uniform distributors of the fluidized bed charcoal regenerator 5 and the catalyst buffer tank 3 are multi-tube type, and the opening ratio is 4%.

[0062] The pyrolysis gas from the high-t...

Embodiment 2

[0067] The device used in this embodiment includes a pyrolysis cyclone separator 1, a multistage tar cracking reactor 2, a catalyst buffer tank 3, a riser carbon oxidation reactor 4, a fluidized bed charcoal regenerator 5, a cyclone dust collector 6, a Heat cooler 7, oil-gas separator 8, induced draft fan 9 and thermostat 10. The multi-stage tar cracking reactor 2 is composed of 4 stages of cyclone contact separators, wherein the form of cyclone contact separators can be Humboldt type. The inner diameter of the riser charcoal oxidation reactor 4 is 500mm, and the height is 15m; the inner diameter of the lower straight cylinder part of the fluidized bed charcoal regenerator 5 is 1500mm, and the height is 5m; the inner diameter of the catalyst buffer tank 3 is 800mm, and the height is 2m; The bottoms of the bed charcoal-burning regenerator 5 and the catalyst buffer tank 3 are equipped with cone-shaped distributors with an opening ratio of 4.5%.

[0068] The pyrolysis gas from t...

Embodiment 3

[0073]The device used in this embodiment includes a pyrolysis cyclone separator 1, a multistage tar cracking reactor 2, a catalyst buffer tank 3, a riser carbon oxidation reactor 4, a fluidized bed charcoal regenerator 5, a cyclone dust collector 6, a Heat cooler 7, oil-gas separator 8, induced draft fan 9 and thermostat 10. The multi-stage tar cracking reactor 2 is composed of 4 stages of cyclone contact separators, wherein the form of cyclone contact separators can be Humboldt type. The inner diameter of the riser charcoal oxidation reactor 4 is 750mm and the height is 10m; the inner diameter of the lower straight cylinder part of the fluidized bed charcoal regenerator 5 is 2000mm and the height is 7m; the inner diameter of the catalyst buffer tank 3 is 1000mm and the height is 2.5m; Bottoms of the fluidized bed charcoal-burning regenerator 5 and the catalyst buffer tank 3 are both provided with plate-tube distributors, and the opening ratio is less than 4.6%.

[0074] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com