Fully dry converter gas purification and recovery system and purification and recovery method

A converter gas recovery method technology, applied in waste gas treatment, manufacturing converters, climate sustainability, etc., can solve the problems of fan impeller sticky dust, low waste heat recovery, high nitrogen consumption, etc., to reduce dust content, The effect of saving water and electricity resources and reducing the cost of steelmaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

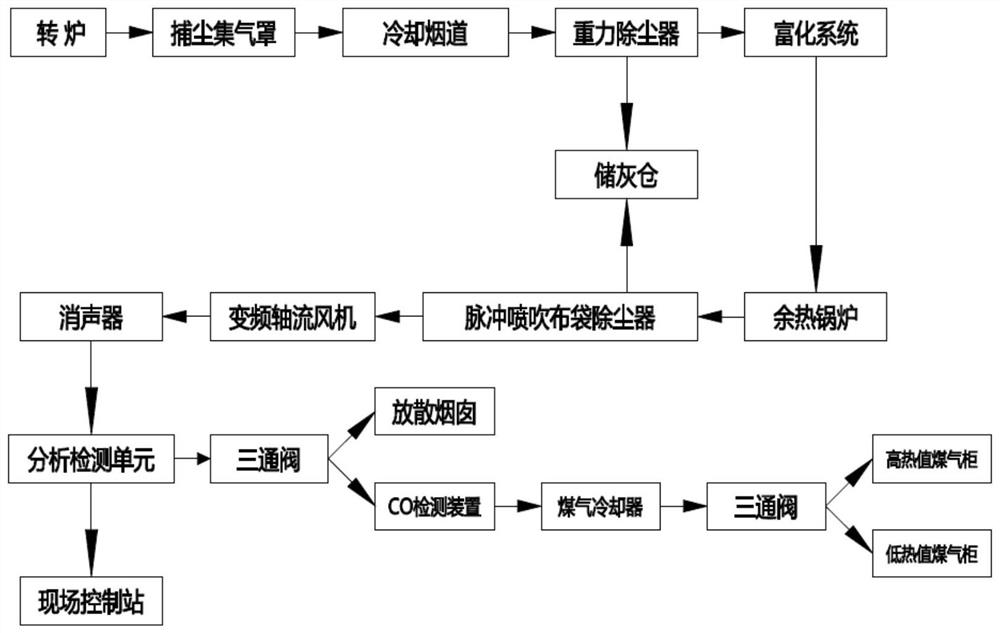

[0028] see figure 1 , and now the fully dry converter gas purification and recovery system provided by the present invention will be described. The all-dry converter gas purification and recovery system includes a dust-collecting gas-collecting hood, a gravity precipitator, a coal gas enricher, a waste heat boiler, a bag filter, a pressurizing unit and an analysis and detection unit; The exhaust port is connected to collect the gas discharged from the converter; the gravity dust collector is connected to the dust collecting hood through the cooling flue, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com