Production method for capturing and recovering CO2 from blast furnace gas for converter steelmaking

A blast furnace gas and blast furnace technology, which is applied in the field of gas recovery and utilization and iron and steel smelting to achieve the effects of high production efficiency, improved quality and calorific value, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

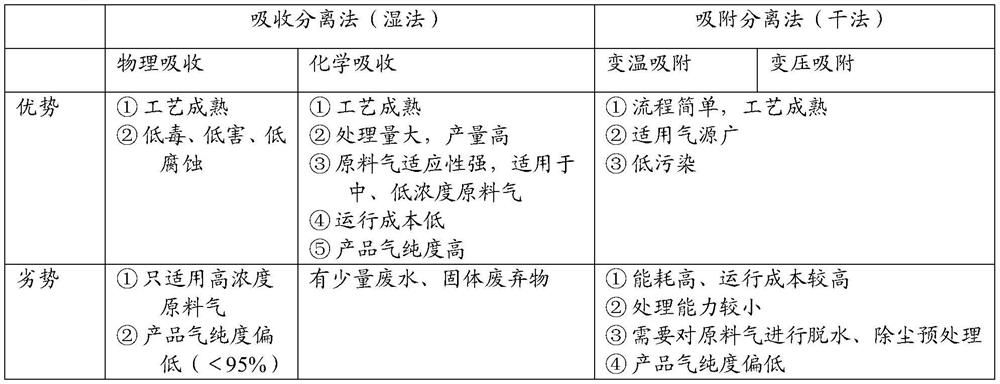

Method used

Image

Examples

Embodiment 1

[0061] (1) Raw gas dust removal

[0062] The raw material used in this example is a blast furnace gas, and the pressure is about 15 kPa, and the component is shown in Table 2.

[0063] Table 2

[0064]

[0065] From the shot of the blast furnace gas, the branch pipe gas is divided, and the flow rate is 600 nm. 3 / min (divided into the CO 2 The product requirements are adjusted), and the water washing dust is transferred to the heat exchanger to adjust the temperature to about 30 to 40 ° C, and the inlet of the absorption tower is sent.

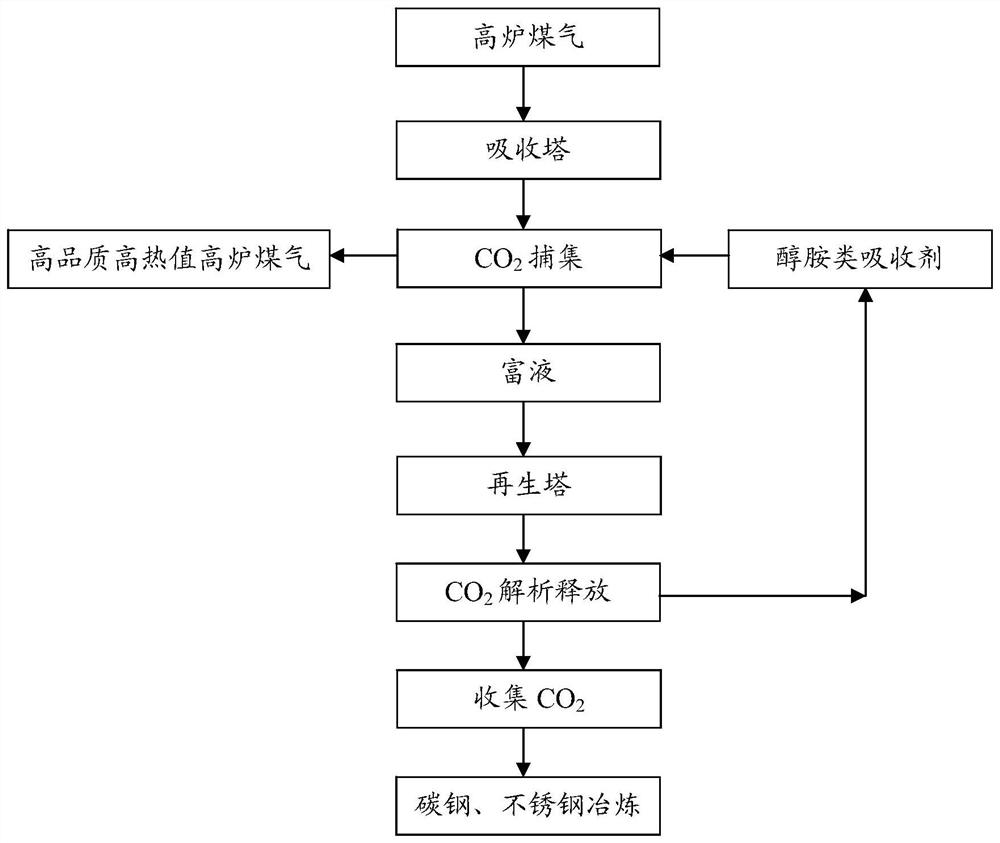

[0066] (2) CO 2 Capture

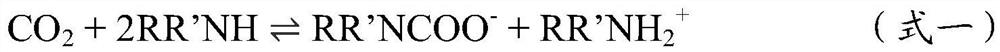

[0067] The raw blast furnace gas entry from the bottom end of the absorption tower, and the absorption tacrollamine adsorbent (MDEA (23 wt%) + DEA (35 wt%), that is, in the alkylamine adsorbent solution, the concentration of MDEA is 23% by weight, DEA The concentration is 35 wt%; the temperature is about 30 to 35 ° C) CO 2 Adsorption reaction, alkylamine melt and blast furnace gas molar ratio is 1: 1.2. Adsorbed CO2 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com