Pump-free direct current furnace starting system capable of recycling working medium and heat comprehensively

A start-up system and DC furnace technology, applied in lighting and heating equipment, preheating, supplementary water supply, etc., can solve the problems of working fluid and heat loss, heat loss, degradation, etc., achieve excellent recovery effect, reduce infrastructure investment, eliminate The effect of import dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

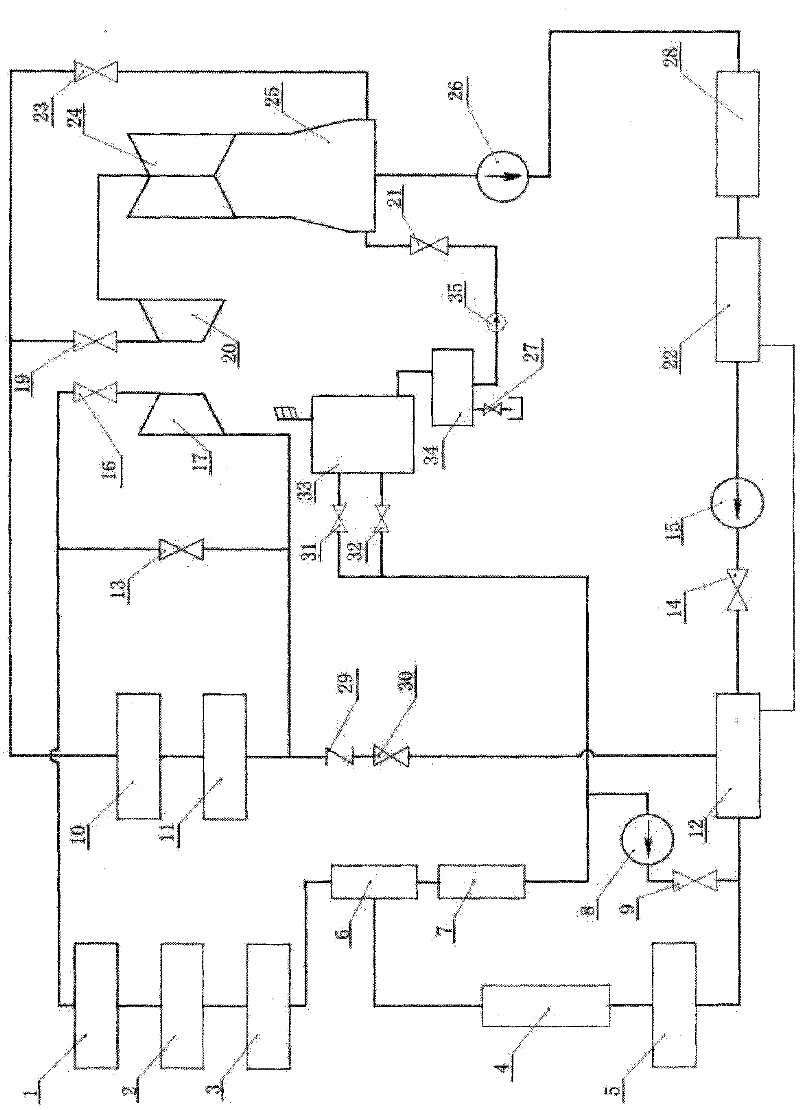

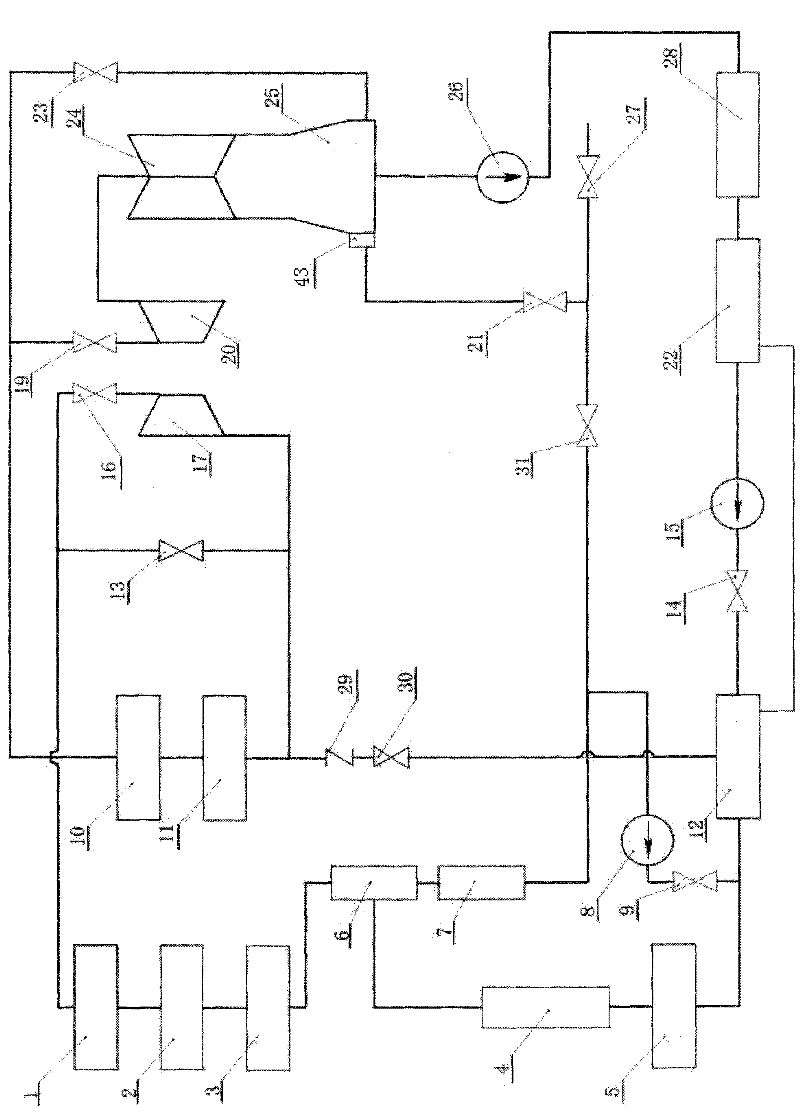

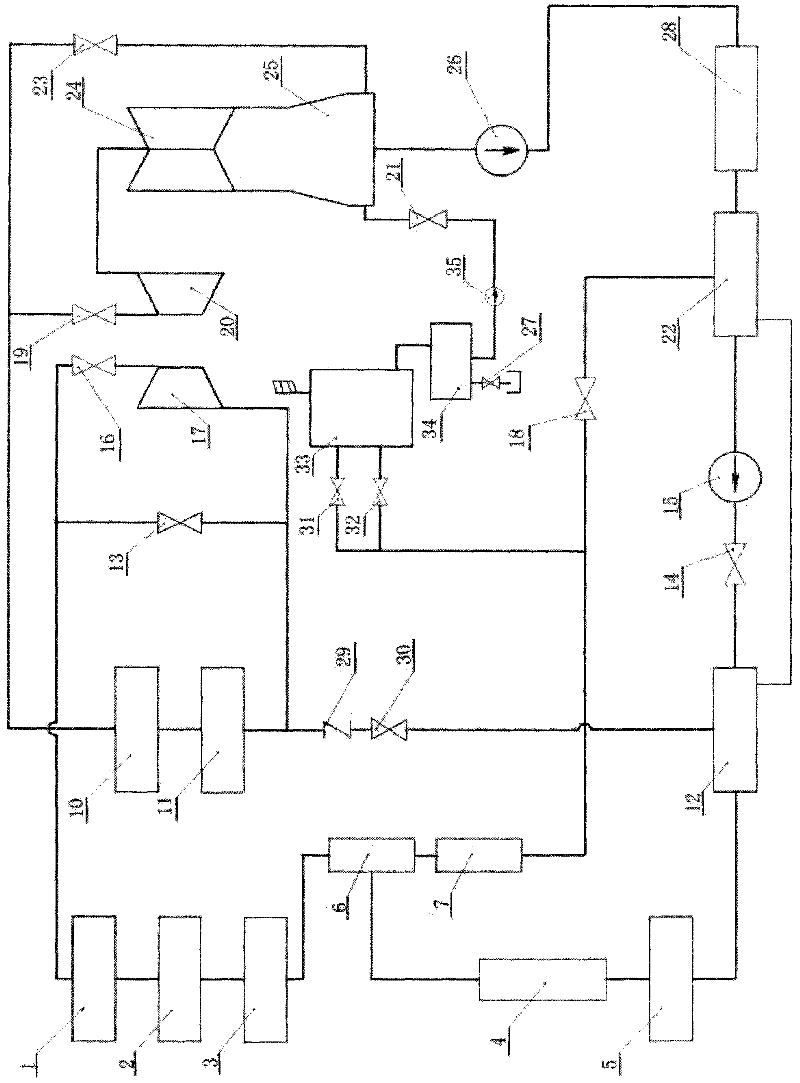

[0089] The following takes a 1000MW power plant supercritical DC furnace as an example, combined with Figure 5 , to further illustrate the pumpless DC furnace start-up system of the present invention that can fully recover working fluid and heat:

[0090]The start-up system of the pumpless DC boiler capable of fully recovering working fluid and heat of the present invention includes a steam-water separator (6), a water storage tank for the steam-water separator (7), an outlet shut-off valve for the water storage tank (42), and a separator water level regulating valve (31). , No. 1 high-pressure inlet steam shut-off valve (39), No. 2 high-pressure inlet steam shut-off valve (40), No. 3 high-pressure inlet steam shut-off valve (41), No. 1 high-pressure heater (44), and No. 2 high-pressure heater (45), No. 3 high-pressure heater (46), No. 1 high pressure drain regulating valve (47), No. 2 high pressure drain regulating valve (48), No. 3 high pressure drain regulating valve (49),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com