Sublance fixed-carbon fault emergency treatment method

An emergency treatment and failure technology, applied in the field of iron and steel smelting, can solve the problems of excessive oxygen supply in auxiliary blowing, decline in experience and skills, and low oxygen supply in auxiliary blowing, so as to reduce the risk of low oxygen at the end point, high phosphorus and molten steel peroxidation occurrence, improving forecast accuracy and timeliness, and ensuring correctness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] In this embodiment, a method for emergency treatment of faults of sub-gun carbon determination is provided, and the steps include:

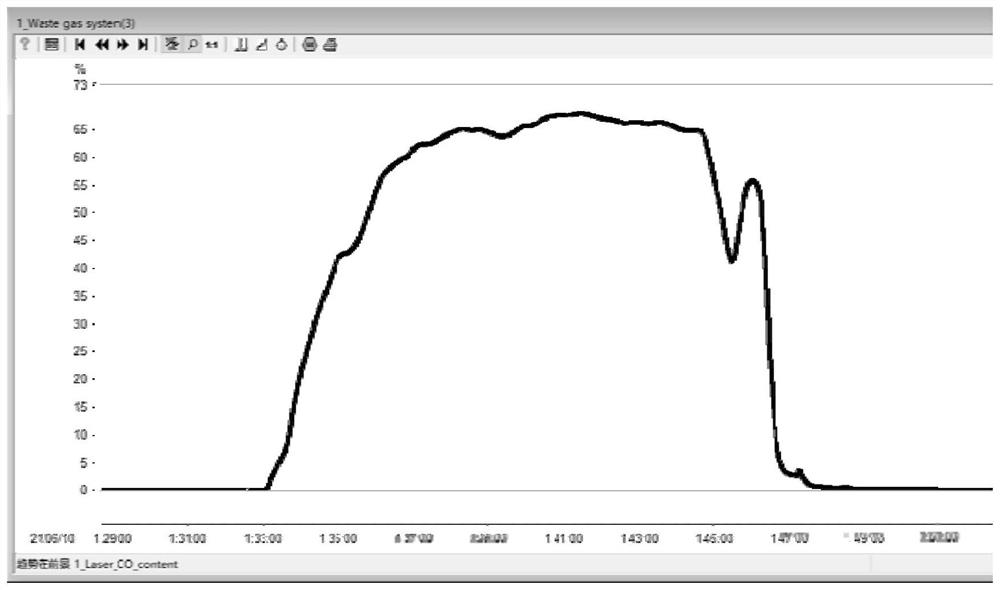

[0033] S01, the pre-established carbon content prediction equation: [C]=A+B×(CO)%, wherein, [C] is the carbon content of molten steel, A and B are the coefficients corresponding to the converter, and (CO)% is the sub-gun setting Peak CO content in converter gas after carbon measurement;

[0034] S02. When the failure of sub-gun carbon determination occurs, obtain the peak value of CO content in converter gas after this measurement (CO) 0 %, and the peak (CO) 0 % is substituted into the carbon content prediction equation to obtain the predicted value of molten steel carbon content [C 0 ];

[0035] S03, according to the predicted value of the carbon content of the molten steel [C 0 ], to determine how to smelt in the future.

[0036] For converters equipped with sub-lances, in order to improve the success rate of sub-lance measurement, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com