Recovery method of steel slag residual heat and system thereof

A waste heat recovery system and waste heat recovery technology are applied in the field of iron and steel metallurgy energy saving and secondary energy recovery, which can solve the problems of physical heat and phase change heat without industrialized recovery methods, and achieve saving and corresponding power consumption, elimination of environmental pollution, The effect of saving drying energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

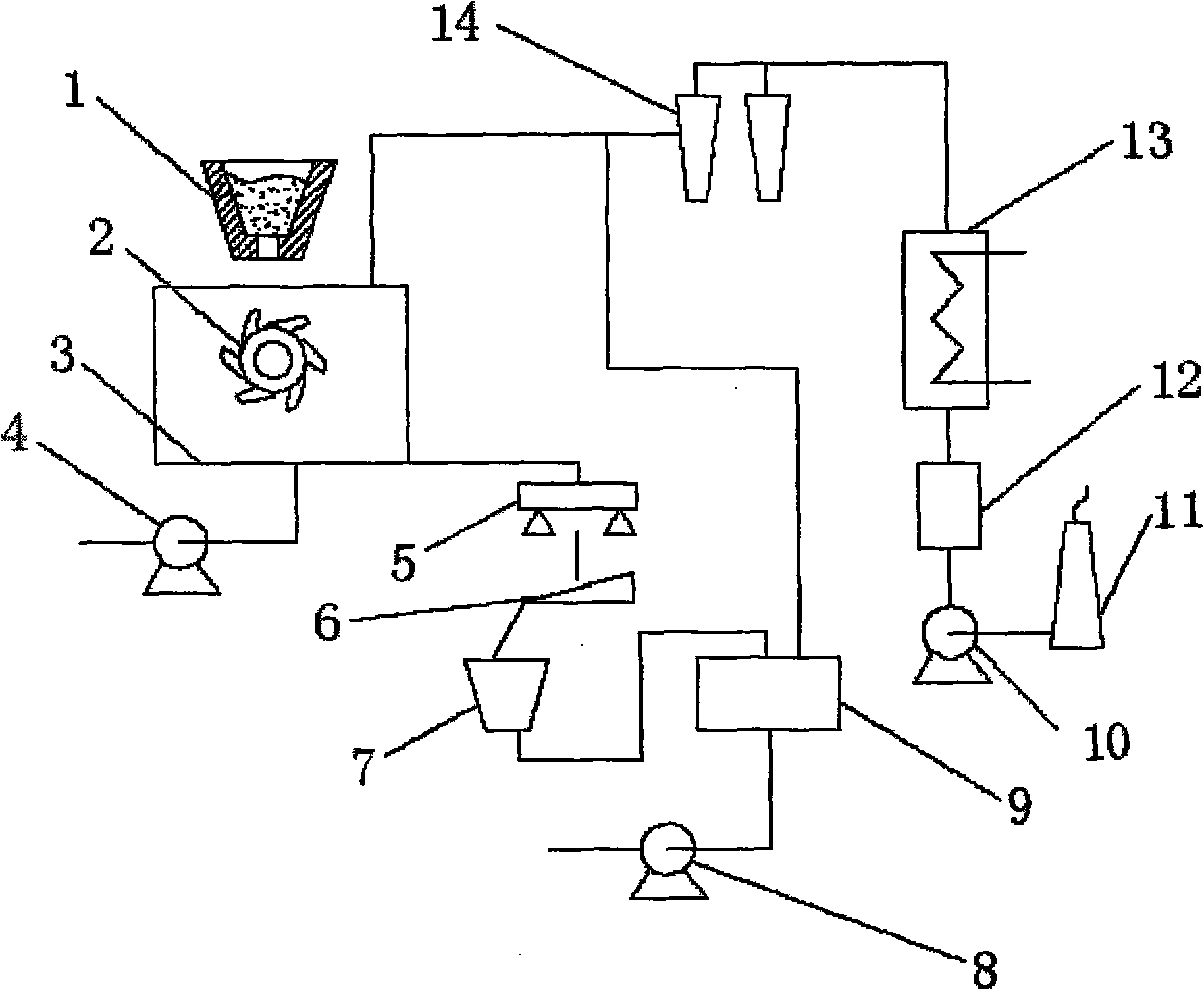

[0022] Such as figure 1 As shown, the steel slag waste heat recovery system consists of steel slag flow distributor 1, water-cooled granulation wheel 2, primary fluidized bed 3, primary cooling fan 4, weighing machine 5, vibrating screen 6, hot slag storage bin 7, secondary cooling Fan 8, secondary fluidized bed 9, exhaust fan 10, chimney 11, dust collector 12, waste heat boiler 13, cyclone dust collector 14. In order to realize the uniform flow of steel slag entering the waste heat recovery system, first pour high-temperature liquid steel slag into the steel slag flow distributor 1, which is made of refractory material and has a slag outlet; in order to ensure reliable operation at high temperatures And it has a long service life. The granulation wheel 2 used for steel slag crushing is cooled by water in the axial direction; in order to achieve the purpose of continuous heat production, a two-stage fluidized bed is used for gas-slag heat exchange. A weighing machine 5, a vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com