Steel production planning-based energy forecasting method

A technology of production planning and forecasting methods, applied in the energy industry, comprehensive factory control, sustainable manufacturing/processing, etc., can solve problems such as rational allocation of energy and power, balanced production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

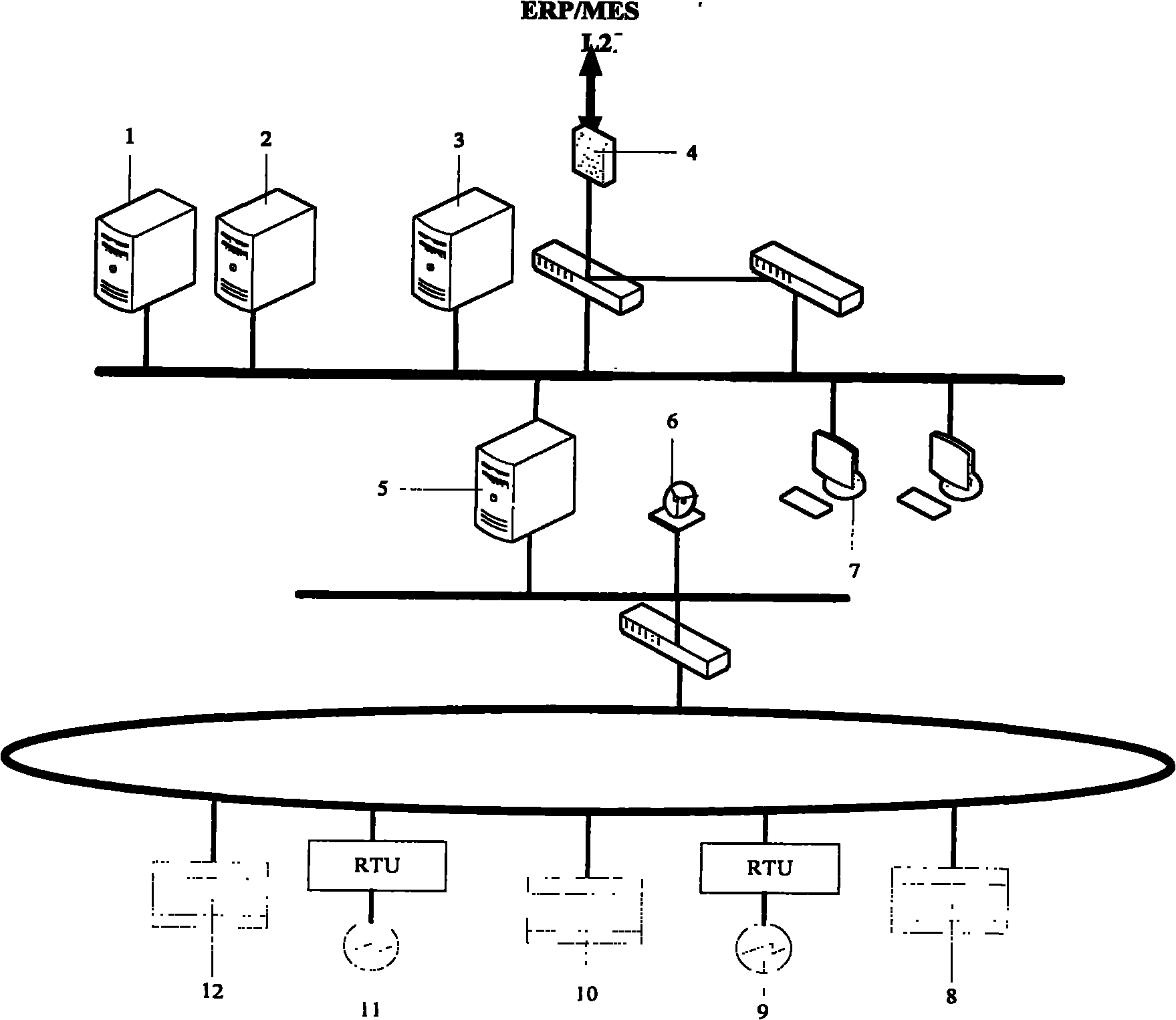

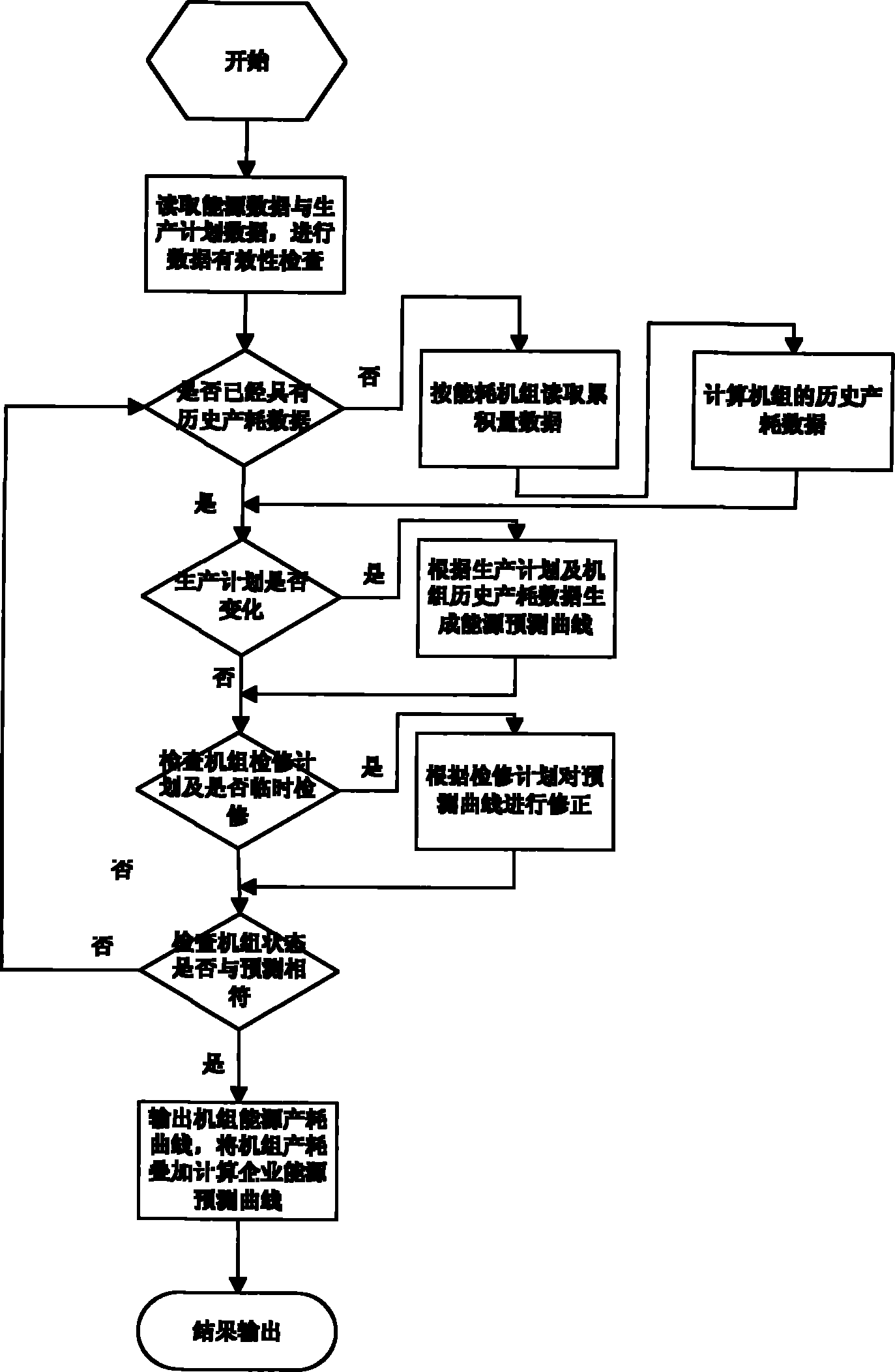

[0058] Example: figure 1 , figure 2 , image 3 As shown, the hardware of this embodiment includes an energy dispatching operation terminal and a server and a management network based on the system, and establishes a data acquisition network with the meters of the energy-consuming unit, and connects through optical fibers to realize data interaction between them.

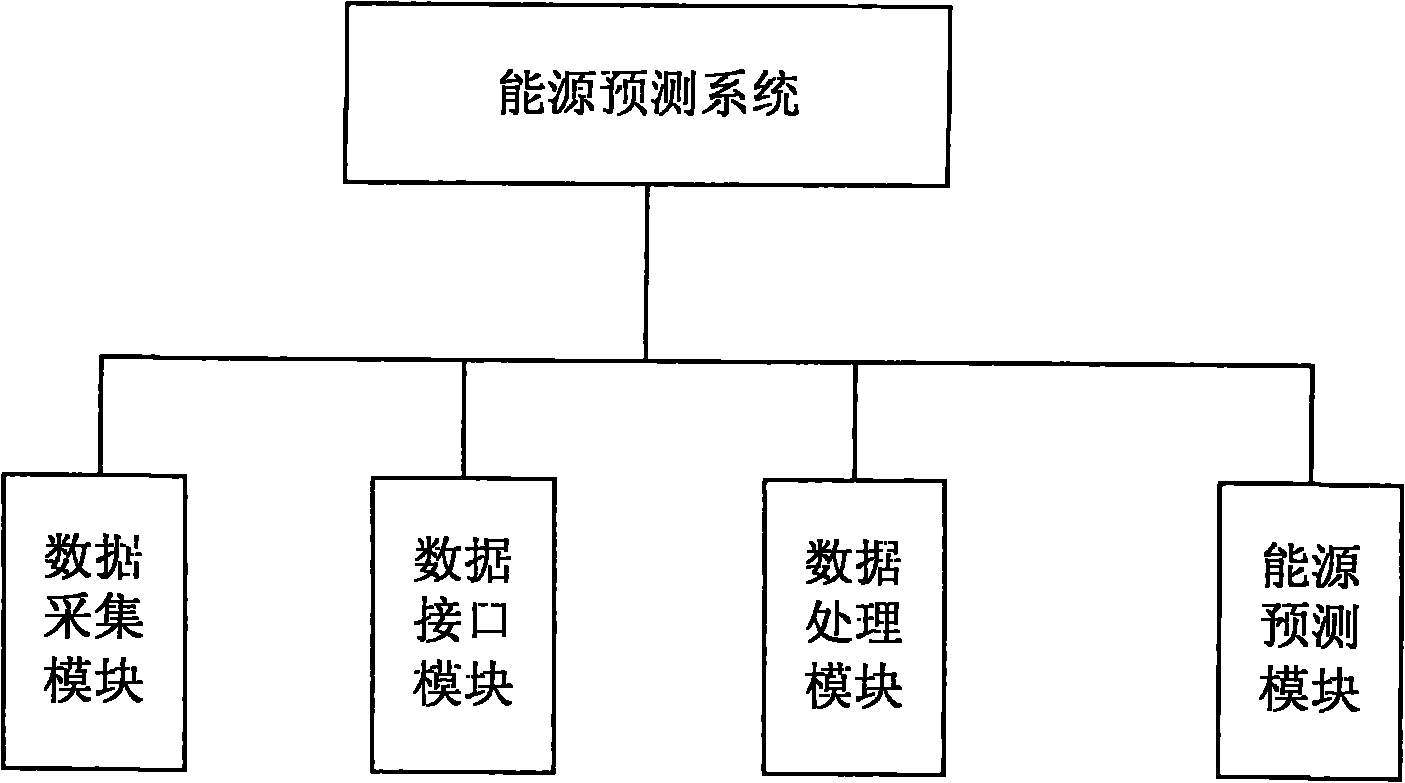

[0059] The supporting software for the above system includes data acquisition module program, data interface module program, data processing module program, and energy forecasting module program, which realize the data collection of energy-consuming units, statistics of unit historical data, and multi-energy medium prediction functions based on production planning .

[0060] The network of the present invention is a multi-service complex network integrating on-site instrument data collection, energy monitoring, energy management, and data backup. The whole system is composed of three layers of networks. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com