Method for processing dust containing zinc and lead in steel plant through closed cupola furnace

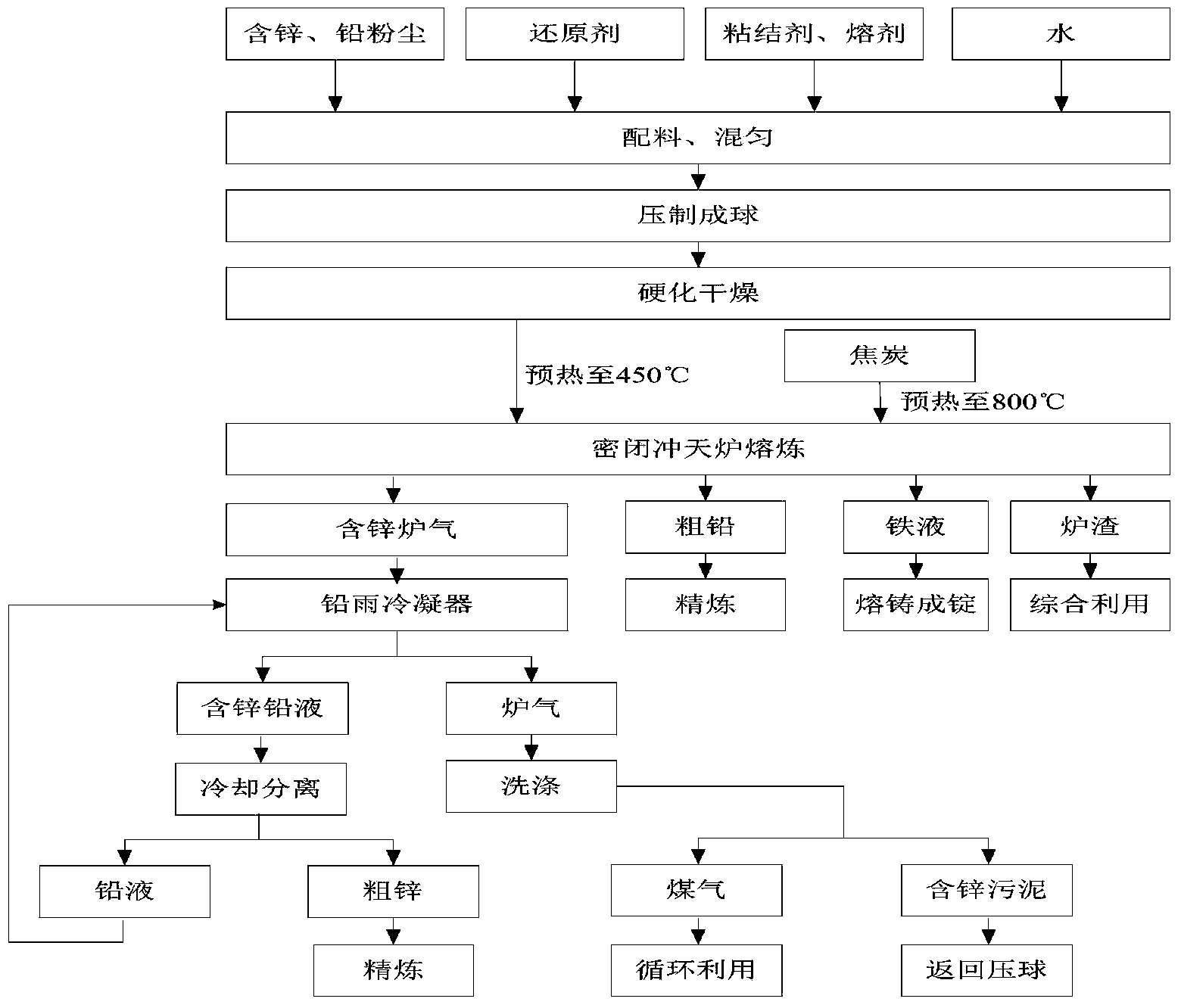

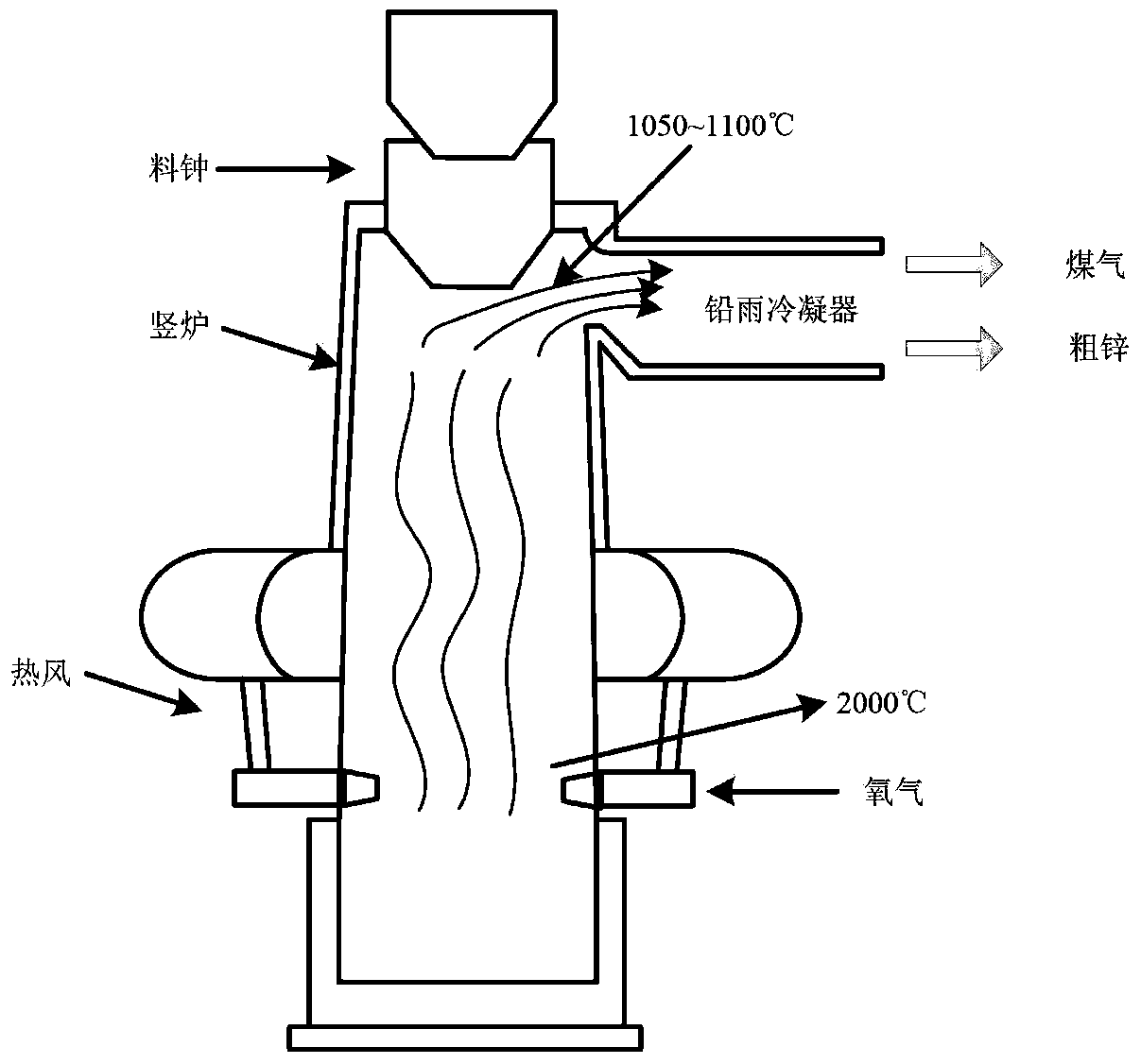

A process method, the technology of cupola, applied in the field of lead dust process, zinc-containing, using closed cupola to treat zinc-containing, lead dust treatment process, can solve the problem of low energy utilization efficiency, affecting operating costs, short equipment operating cycle, etc. problems, to achieve significant economic and environmental benefits, high processing efficiency and product added value, and strong adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0019] A kind of electric furnace dust is selected as the raw material, and its composition is Fe: 35%, Zn: 13%, Pb: 3.5%; coke powder is used as the reducing agent, the fixed carbon content is about 85.5%, the ash content is about 12.5%, and the volatilization The content is about 2%; silica powder is used as the flux, and its SiO 2 The content is about 98%; cement is used as the binder. Put the electric furnace dedusting ash into the dryer for drying, add coke powder, silica powder, cement and water according to the ratio of electric furnace dedusting ash: coke powder: silica powder: cement: water about 100:17:5:10:15, fully After mixing, press it into blocks under a pressure of not less than 20MPa, and cure it for 72 hours in an environment with a temperature of 20-30°C and a humidity of ≥95%, and send it to the stockyard for stacking after curing.

[0020] The electric furnace dedusting ash pellets and coke are sent to the preheater respectively for preheating, the pellet...

Embodiment approach 2

[0022] A blast furnace dust removal ash and an electric furnace dust removal dust are selected as raw materials. The composition of the blast furnace dust removal dust is Fe: 31%, Zn: 9%, Pb: 0.5%, and C: 21%. The composition of the electric furnace dust removal dust is consistent with that of Embodiment 1 . Lime is used as flux. Add blast furnace dust and electric furnace dust to the dryer for drying, and mix according to the ratio of blast furnace dust: electric furnace dust: quicklime: cement: water about 65:35:2:10:15, mix well Pressed into blocks under a pressure lower than 20MPa, cured for 72 hours in an environment with a temperature of 20-30°C and a humidity of ≥95%, and sent to the stockyard for stacking after the curing is completed. This method can make full use of the carbon in the dust removal dust of the blast furnace, does not need to add additional reducing agent, and can reduce the amount of flux added at the same time.

[0023] The pellets and coke are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com