Locking device for corrugated board box covering machine

A locking device and corrugated cardboard technology, applied in paper/cardboard containers, packaging, transportation and packaging, etc., can solve the problems of decreased precision of guide post screw and inability to position cardboard, achieving low cost, improved rigidity, and small size The effect of ground space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

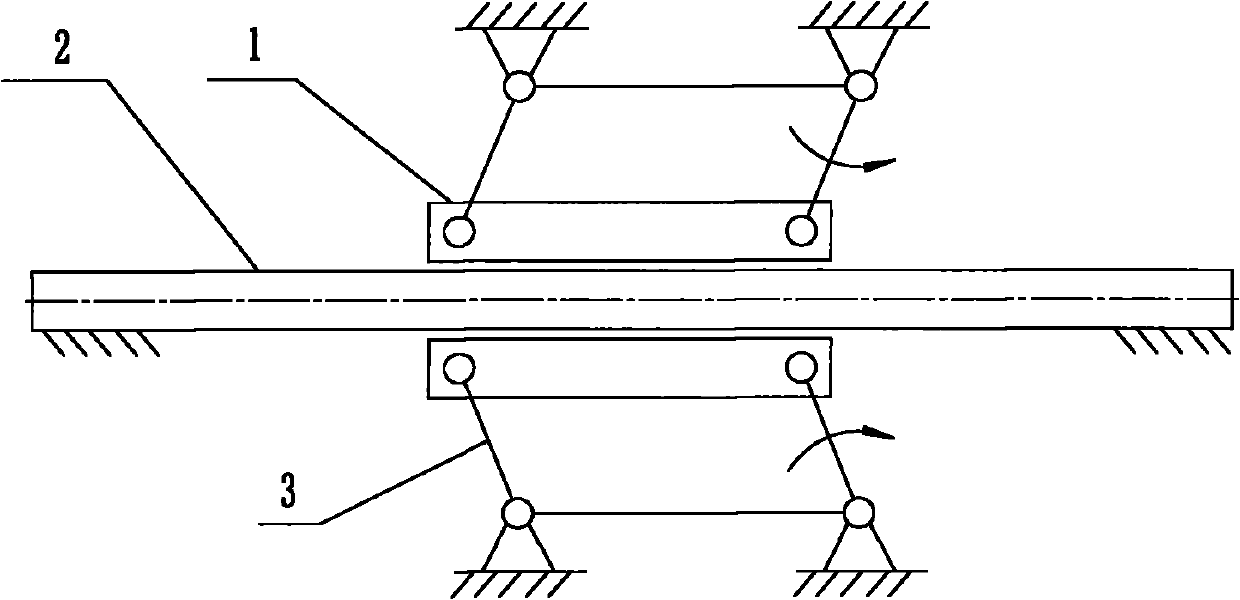

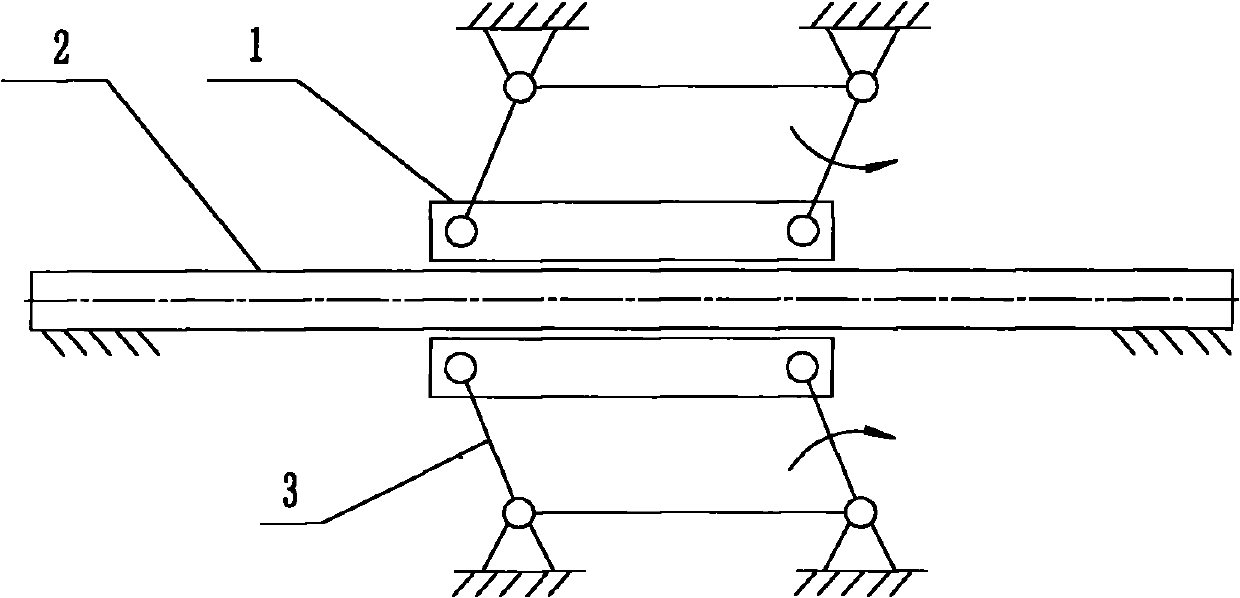

[0016] see figure 1 , figure 2 , is an embodiment of a locking device for a corrugated cardboard box gluer of the present invention, including a cardboard, a cardboard and a frame, a locking bar 2 is fixed on the frame, and two symmetrically arranged relative to the locking bar 2 The locking blocks 1 are fixed on the cardboard, and each locking block 1 is respectively connected with the swing mechanism provided on the same side of the locking bar 2, and the two swinging mechanisms respectively drive the locking block 1 to squeeze the locking bar 1 to lock.

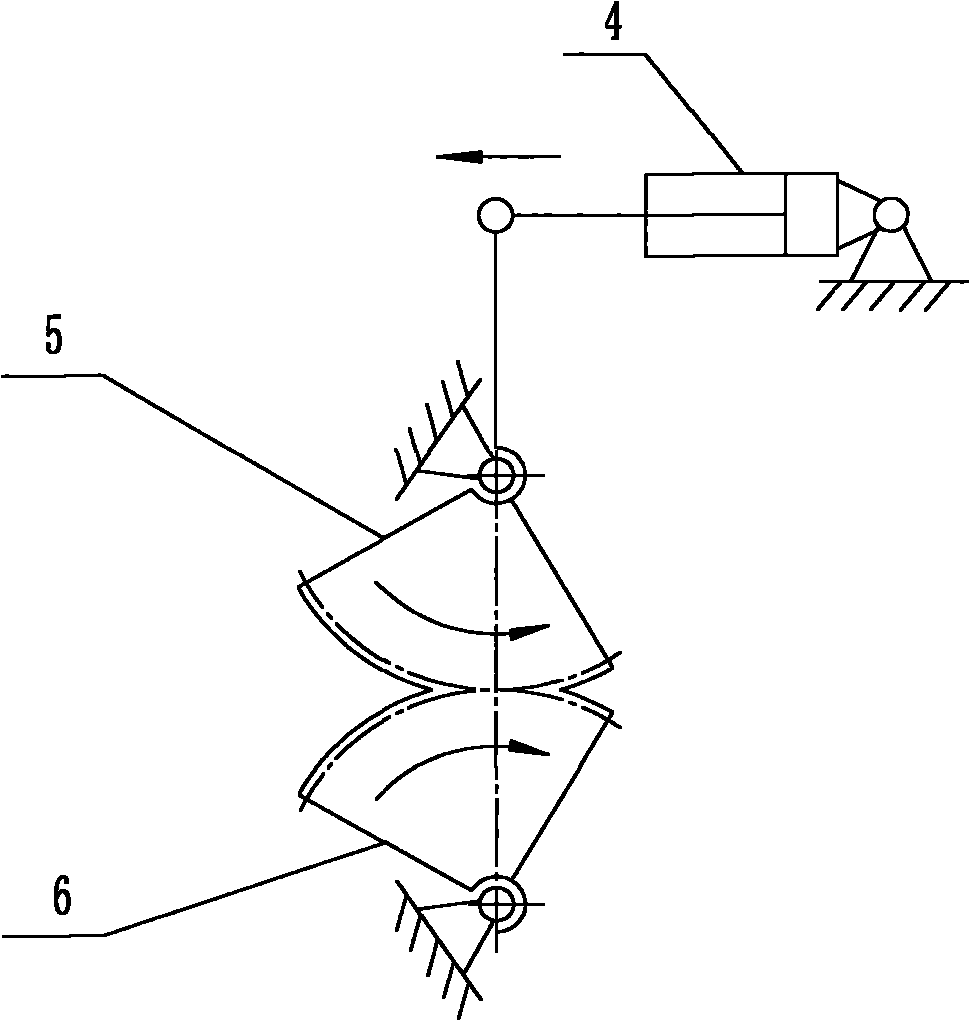

[0017] An embodiment of the above-mentioned swing mechanism is: a parallelogram four-bar linkage mechanism formed by hinged locking block 1 and swing rod 3 . Two sets of parallelogram four-bar linkage mechanisms are arranged on the upper and lower sides of the locking bar 2 respectively. There are a pair of sector gears 5 and 6 that mesh with each other, and the two sector gears 5 and 6 are pivotally connected to the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com