Ceramic ball core for ball valve

A technology of ceramic balls and ball valves, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as easy leakage, chipping of ball cores, and inability to corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

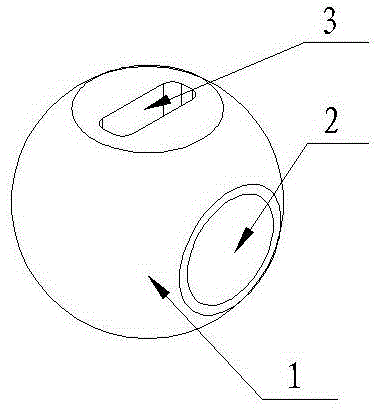

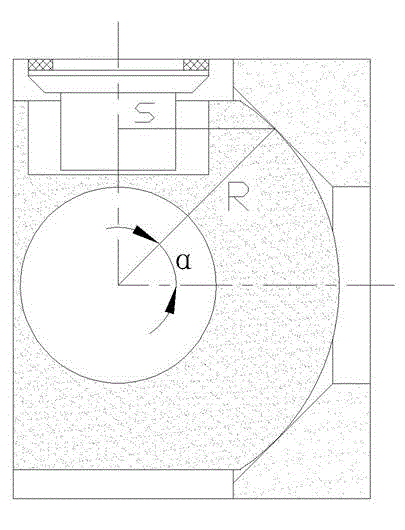

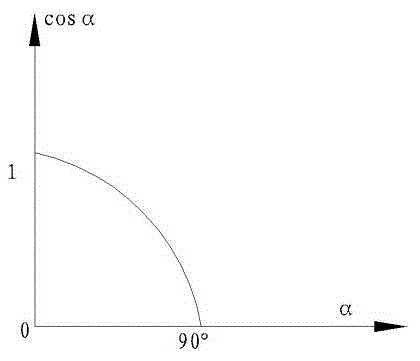

[0062] Embodiment, a kind of ball valve ceramic ball core, refer to figure 1 , figure 2 , the ball core body 1 is provided with a ball core through hole 2 and a valve stem hole 3, and the ratio a of the outer diameter Q of the ball core body 1 to the diameter D of the ball core through hole 2 is greater than or equal to 1.8.

[0063]The core body 1 is made of zirconia structural ceramics. By utilizing the self-lubricating properties of zirconia, the ball valve using this core body 1 can obtain the characteristics of reliable sealing, light torque, high corrosion resistance and wear resistance, and a long service life. Long, high stability, can adapt to the needs of harsh working conditions such as higher and higher wear and strong erosion.

[0064] For the convenience of assembly, the upper and lower ends of the core body 1 are planes, and the stem hole 3 is a rectangular blind hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com