Hot-rolled profile steel door hinge device for container

A technology for door hinges and containers, applied in the field of hinges, can solve problems such as joint deformation, reduced service life, and damage to the hinge part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

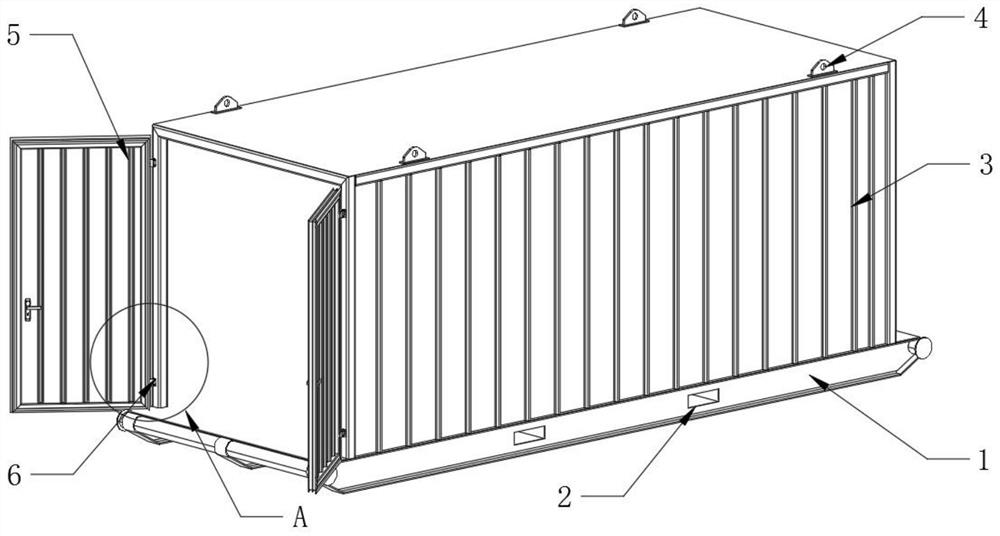

[0028] see figure 1 , a hot-rolled steel door hinge device for containers in the figure, including a base 1, a slot 2, a box body 3, lifting lugs 4 and a door panel 5, and a slot is symmetrically opened in the center of one side of the base 1 2, and the upper surface of the base 1 is fixedly installed with a box body 3, and the edge of the upper surface of the box body 3 is symmetrically fixed and installed with lifting lugs 4, and one side of the box body 3 is symmetrically rotated and installed with a door panel 5, and the door panel 5 A hinge mechanism 6 with multiple structural levels is installed between the box body 3 .

[0029] In the main body of the device, the slot 2 provided on the base 1 can facilitate the connection of transfer parts such as forklifts and the device, and the lifting lug 4 is convenient for hoisting the device as a whole, which can meet the requirements for transferring the device as a whole. The hinge mechanism 6 Realize the rotation opening and ...

Embodiment 2

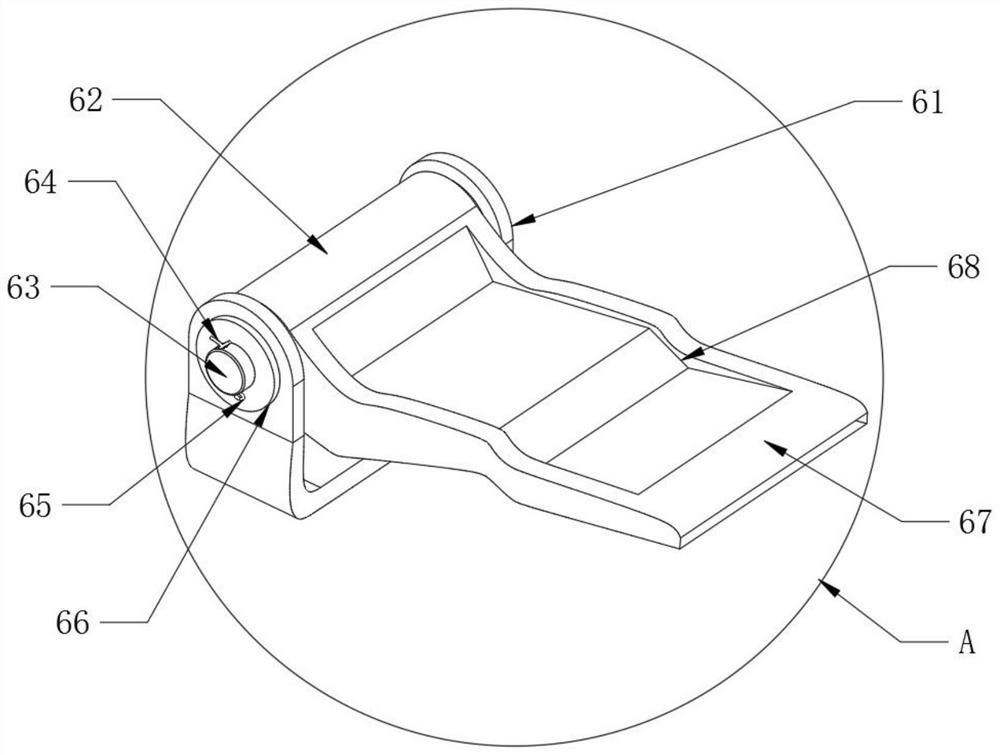

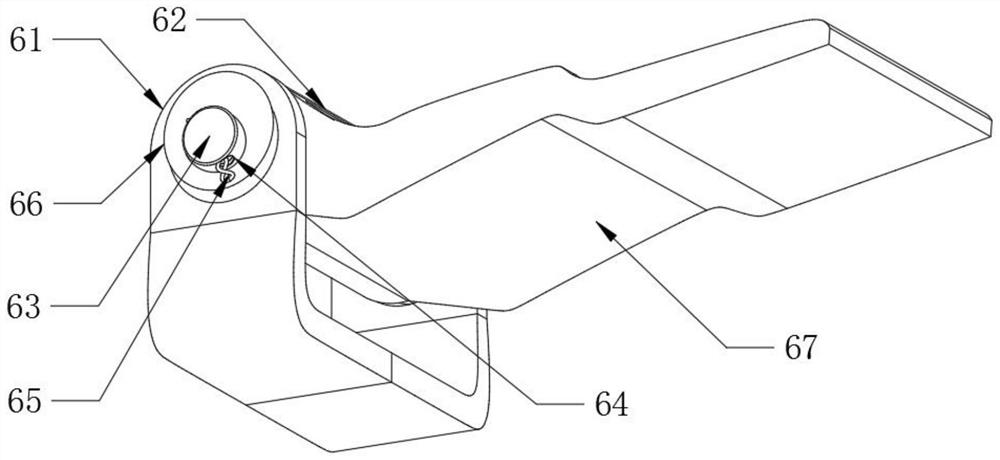

[0040] Such as Figure 5 with Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the base 61 is equidistantly provided with first post grooves 611 on the side close to the box body 3, and the first post grooves 611 are sequentially connected with first guide channels 612, and the chains The side of the plate 67 close to the door panel 5 is equidistantly provided with second column grooves 673 , and the second column grooves 673 are sequentially connected with second guide channels 674 .

[0041]The installation of the hinge mechanism 6 firstly welds the base 61 and the box body 3. During welding, the solder flows into the first column groove 611 from the seam of the base 61 and the box body 3 in a hot-melt state, and passes through the first guide flow. The channel 612 makes the plurality of first column grooves 611 filled with solder, and after cooling, a uniform multi-point column connection structure is formed between the base 61 and the box...

Embodiment 3

[0044] Such as Figure 7 As shown, the difference between this embodiment and the first embodiment is that ribs 672 are symmetrically fixed on one side of the groove 68 on the chain plate 67 .

[0045] This increases the connection transition level between both sides of the groove 68 and the surface of the chain plate 67 , further improving the shear strength of the chain plate 67 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com