Graphite piece and processing method thereof, single crystal growth equipment

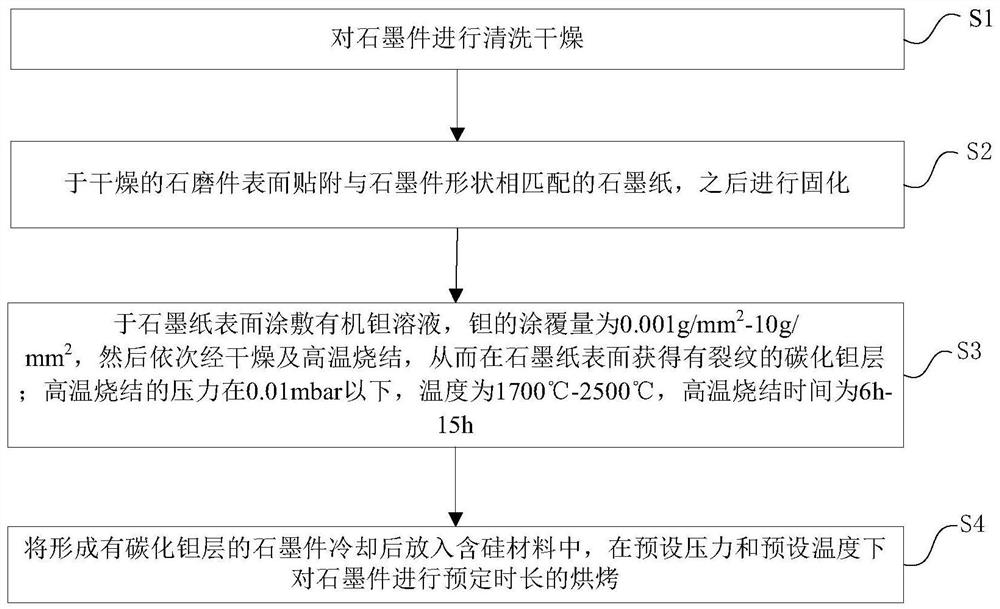

A processing method and technology of graphite parts, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of graphite thermal field being corroded, etc., to improve the quality of single crystal growth, increase mechanical strength, and reduce crystal extrusion The effect of compressive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] 1. Ultrasonic cleaning the surface of the graphite substrate to remove surface impurities, and drying in an oven at 110°C for 8 hours;

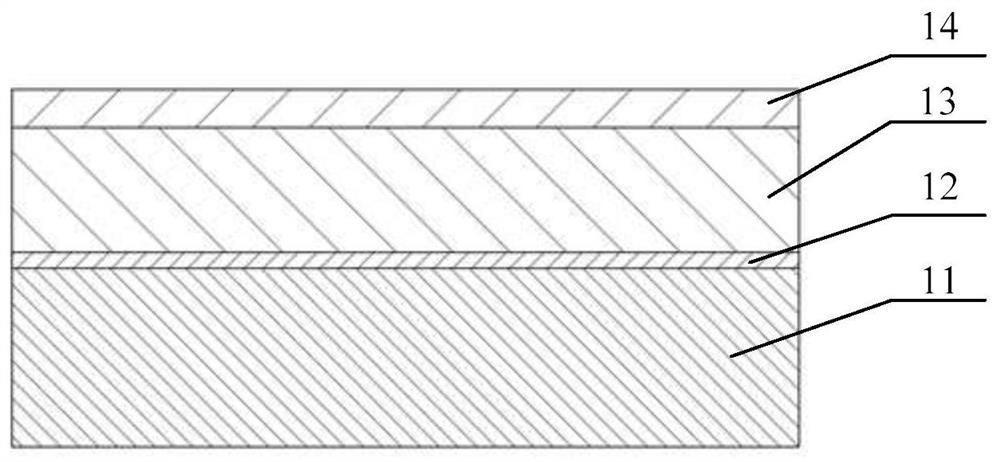

[0052] 2. Coat a layer of phenolic resin on the surface of the dried graphite substrate, and then paste a piece of high-purity graphite paper that matches the shape of the graphite substrate. The thickness of the graphite paper is 0.5mm, and then put the graphite substrate in an oven at 160°C for curing 10h;

[0053] 3. Use tantalum ethoxide and tantalum pentoxide to configure an organic solution with a mass ratio of 1:1, and coat the organic tantalum solution on the surface of the graphite paper. The coating amount of tantalum is 0.15g / mm2, and then put it in a 73°C refrigerator after coating Oven drying for 24 hours;

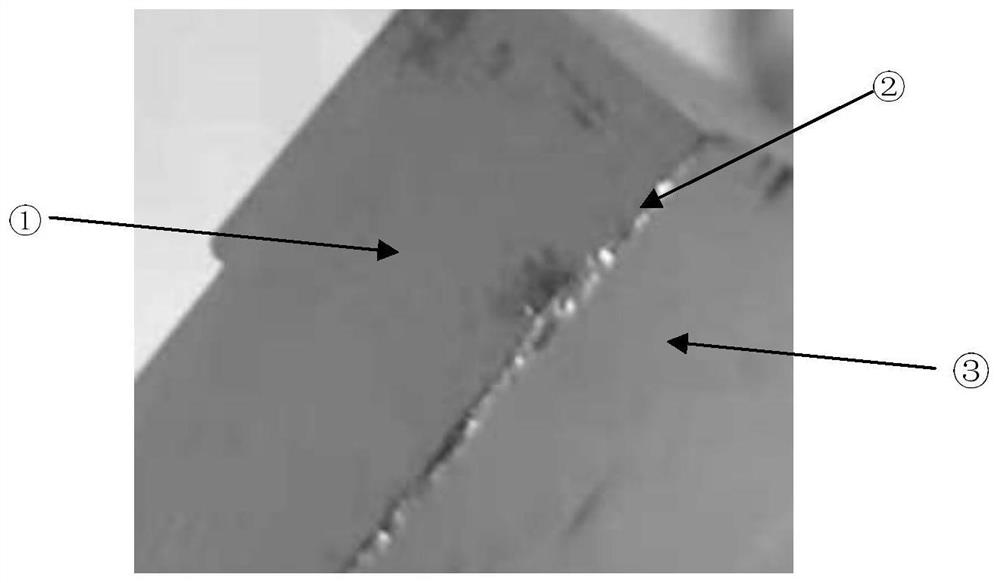

[0054] 4. Put the graphite substrate into the sintering furnace, and keep sintering for 6 hours when the pressure reaches below 0.01mbar and the temperature reaches 2400°C, that is, a tantalum carbide layer is obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com