Wheel disc spigot locating structure of gas turbine rotor and gas turbine rotor

A gas turbine and positioning structure technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of reduced structural durability, high cost, etc., to achieve lower requirements, reduce extrusion stress, and avoid micro-sliding or The effect of relative displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

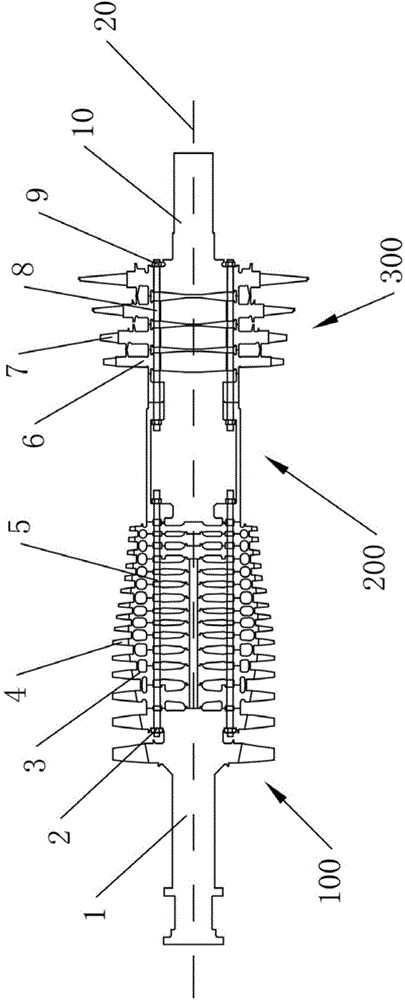

[0024] figure 1 It is a schematic diagram of the structure of the gas turbine rotor, which includes the compressor rotor unit 100 on the compressor side, the intermediate shaft 200 and the turbine rotor unit 300 on the turbine side in order from front to back. The compressor rotor unit includes a compressor shaft head 1, a compressor wheel 3, a circle of circumferentially spaced compressor rotor blades 4, a compressor tie rod 5, and a compressor tie rod nut 2 mounted on the compressor wheel 3. The compressor rotor blade 4 is arranged on the outer side of the compressor wheel 3 and can compress air to perform work under the drive of the compressor wheel 3. Adjacent compressor wheels 3 are axially stacked on each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com