Processor base

A processing machine and workbench technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the support performance of the base, low repetitive positioning, increased weight, etc., to improve the replacement efficiency and the scope of application, The effect of reducing internal stress and extrusion stress, reducing axial force and radial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the drawings and specific embodiments.

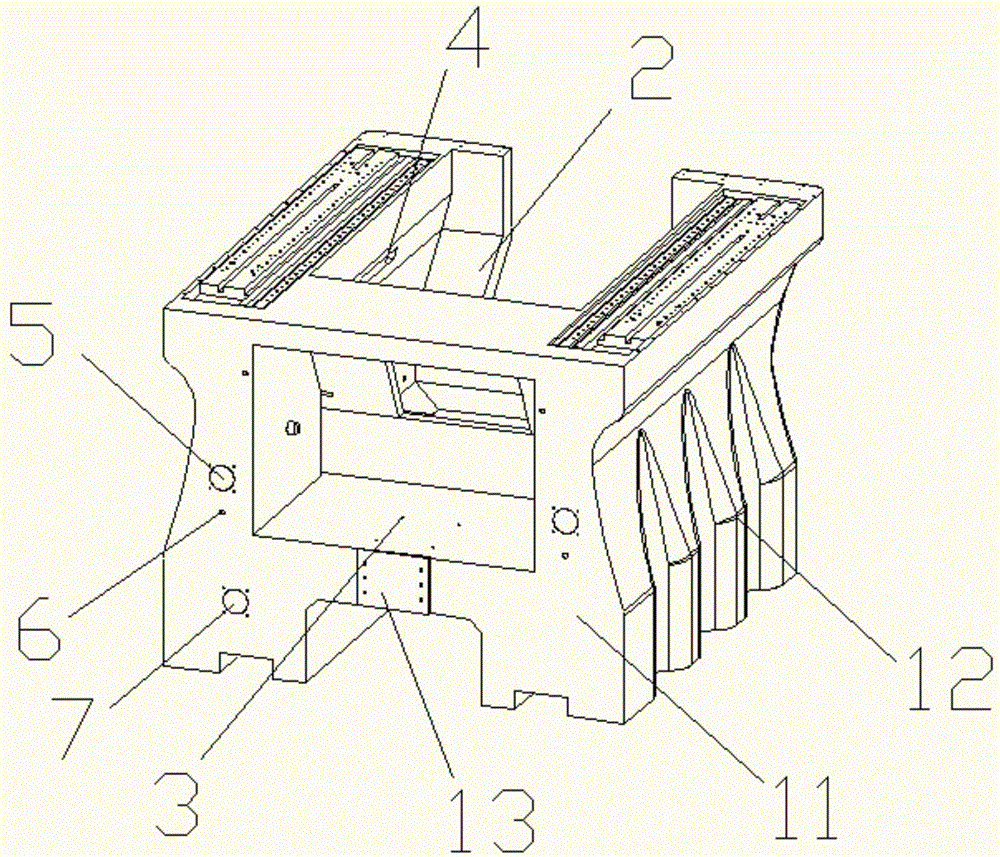

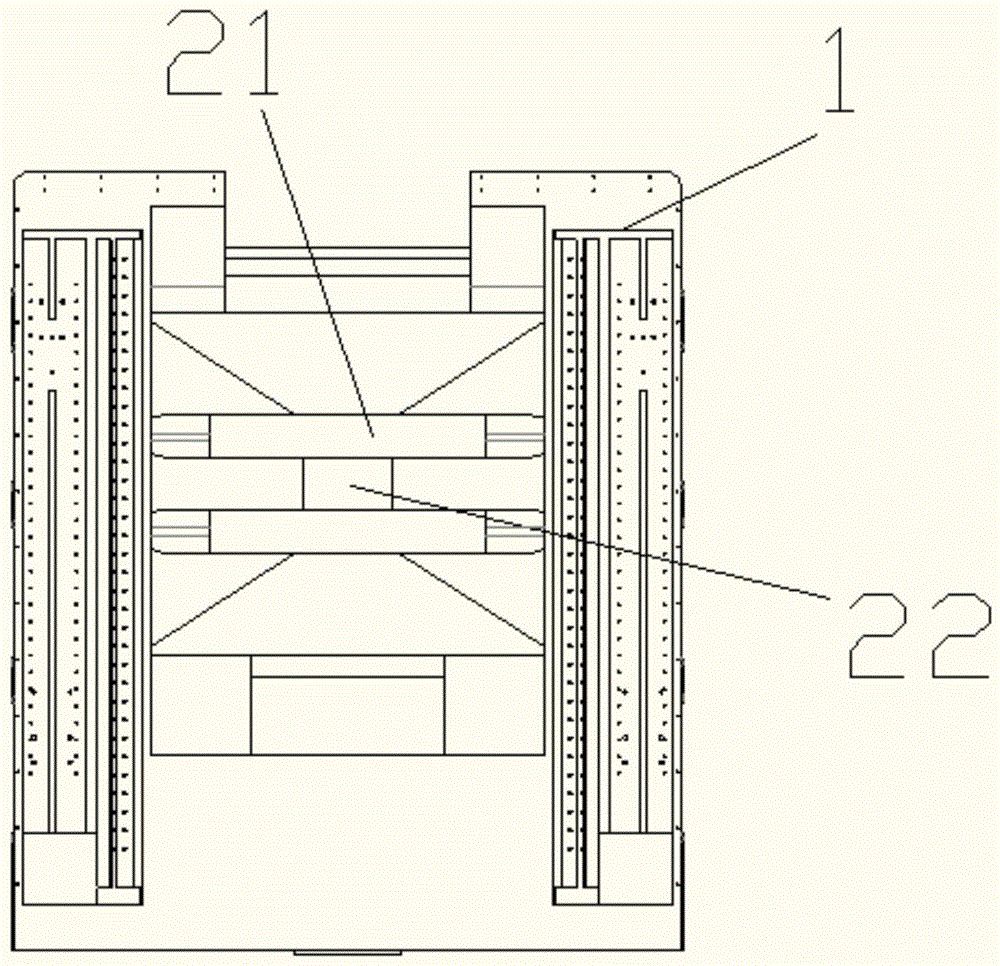

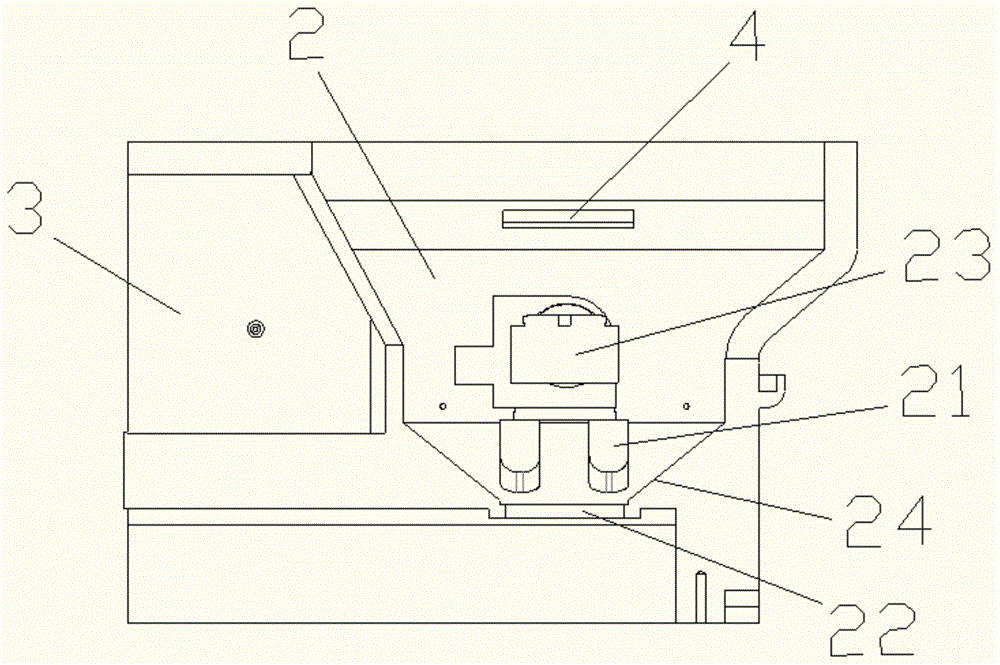

[0029] Such as figure 1 As shown, the side surface 12 of the base body 1 includes a vertical portion at the lower end and an inclined portion at the upper end, and the upper end of the inclined portion is inclined toward the inside of the base body 1. At this time, the two side faces 12 of the base body 1 are formed in cross-sections as A trapezoid, that is, the shape of the end face 11 is a trapezoid. At the same time, the side surface 12 is set in a wave shape, the whole is a house mosaic structure, which can realize the distribution of force in the operation of the machine tool, greatly reduce the axial force and the radial force, and reduce the internal stress and extrusion stress. The unloading force far exceeds the original base. The three-dimensional pyramids mutually support the entire machine bed, improve the rigidity, strength and accuracy of the bed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com