Joint steel frame supporting system for excavating auxiliary tunnel on main-tunnel arch wall and construction method of joint steel frame supporting system

A support system and steel frame technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as arch bias, threats to building safety, and on-site management troubles, achieving high economic and social benefits and widespread Application value, effect of reducing construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in combination with specific embodiments.

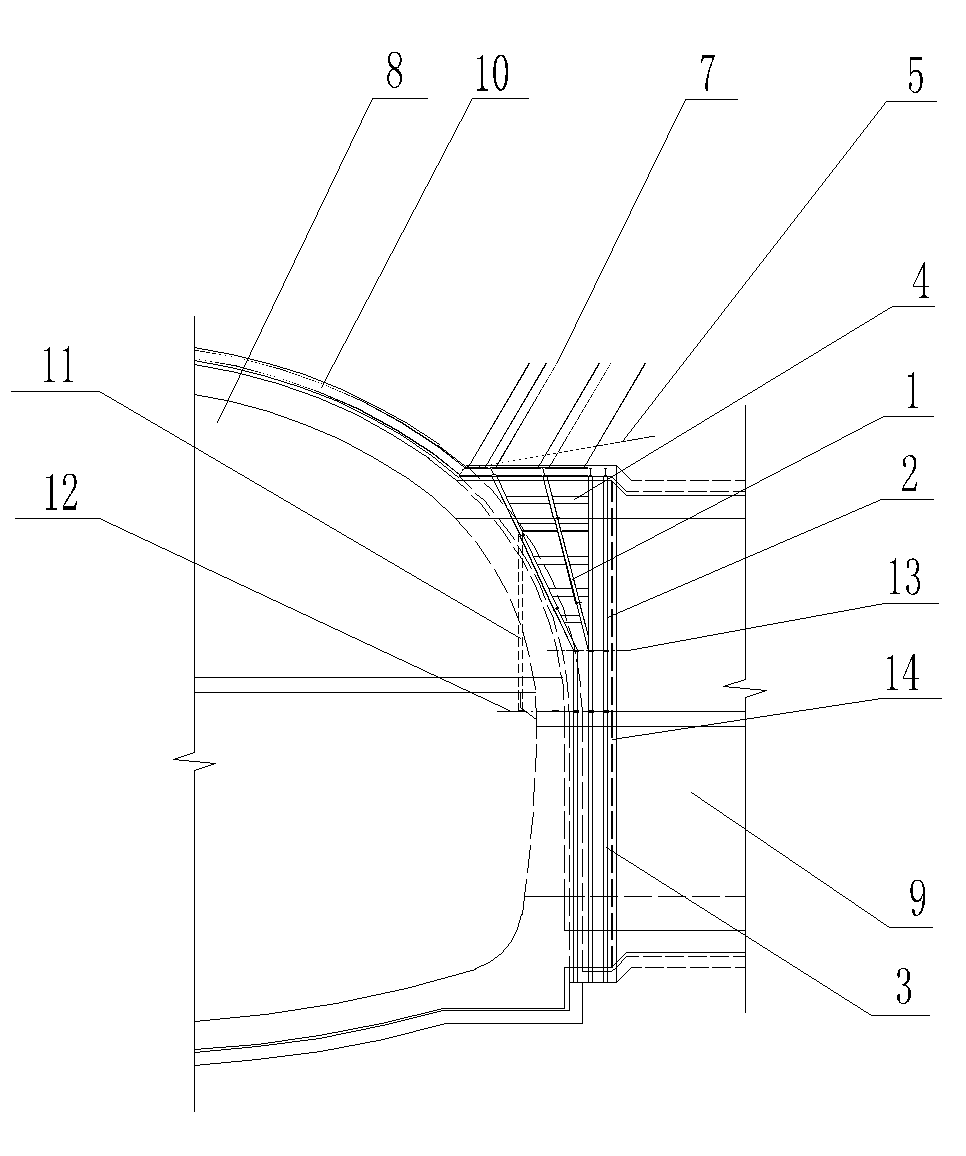

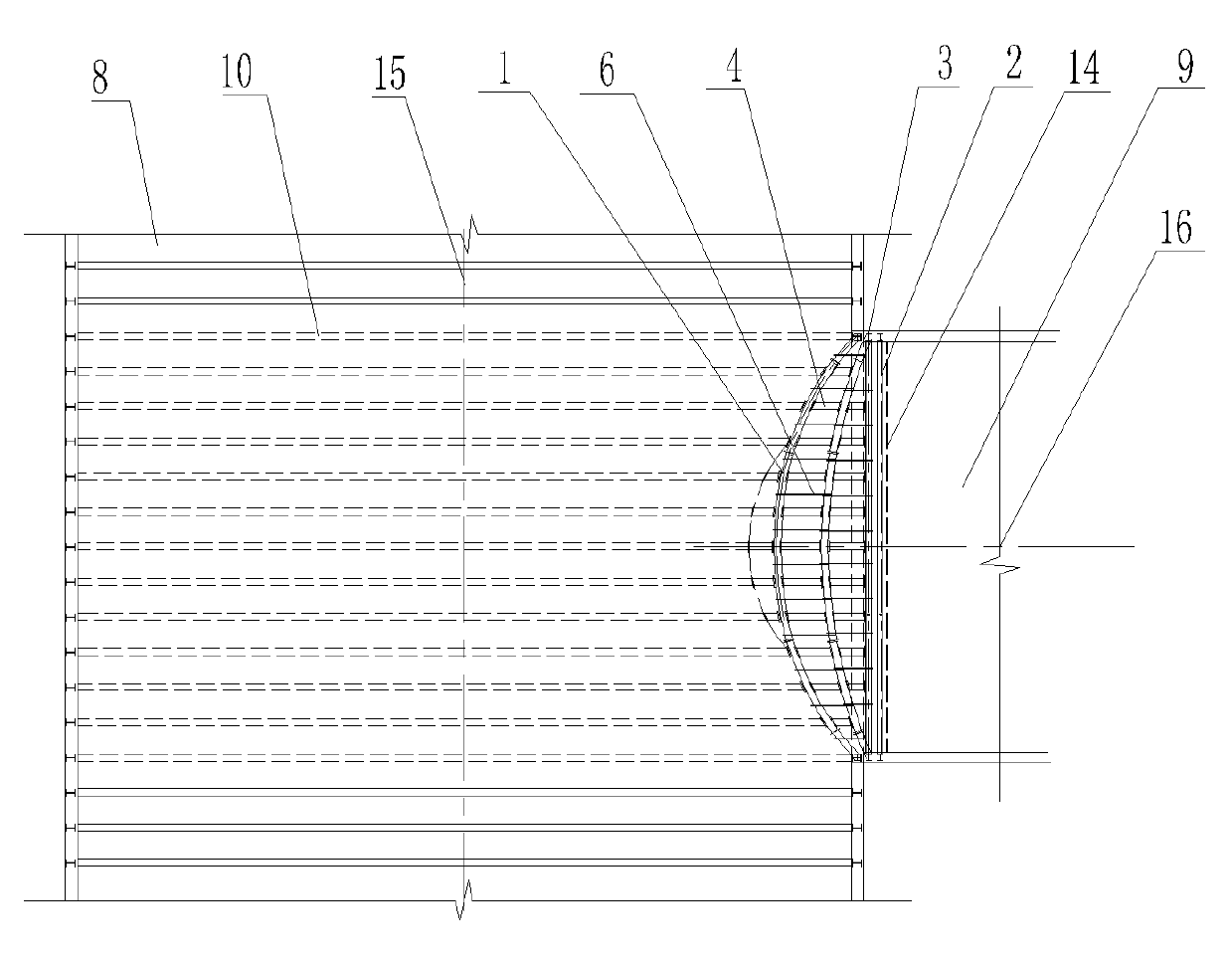

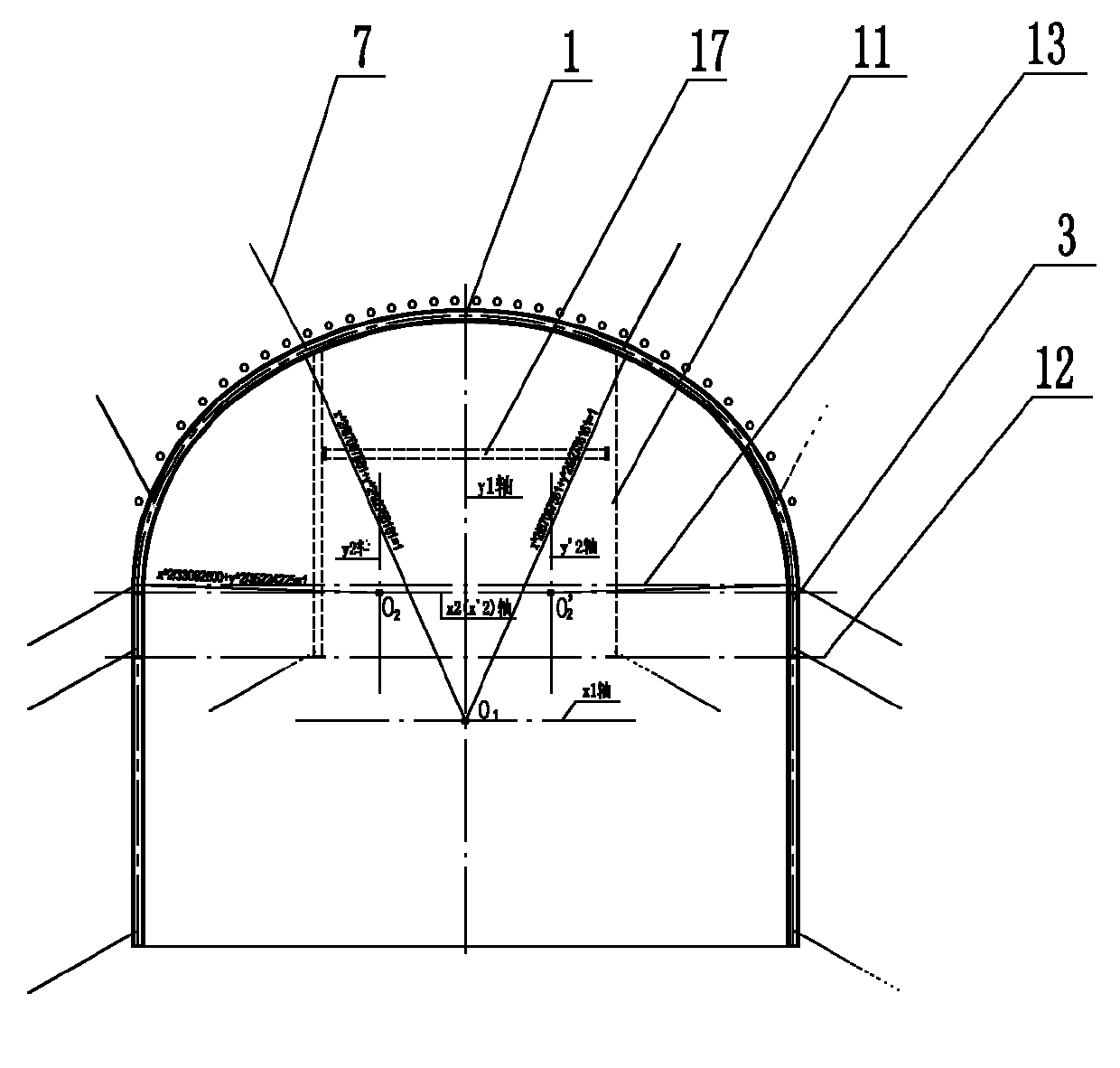

[0035] The interface steel frame support system of the main tunnel arch wall opening the auxiliary tunnel involved in the present invention includes three parts structure, the main tunnel 8, the auxiliary tunnel 9 and the interface steel frame support system between the two, the interface steel frame support system includes inclined Arch arc steel frame 1, vertical arc arc steel frame 2, lower straight wall steel frame 3, horizontal connecting steel frame 4 and arch leading small conduit 5.

[0036]There are multiple lower straight wall steel frames 3 vertically arranged at the two side straight walls at the interface between the main tunnel 8 and the subsidiary tunnel 9, and the upper ends of the lower straight wall steel frames 3 are connected with the arch arc steel frame. Among them, the arc-shaped steel frame near the main tunnel 8 is an inclined arch arc-shaped stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com