Lining structure for super large section water-rich loess tunnel of high-speed railroad

A super-large cross-section, high-speed railway technology, used in tunnel lining, tunnel, shaft lining and other directions to achieve long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

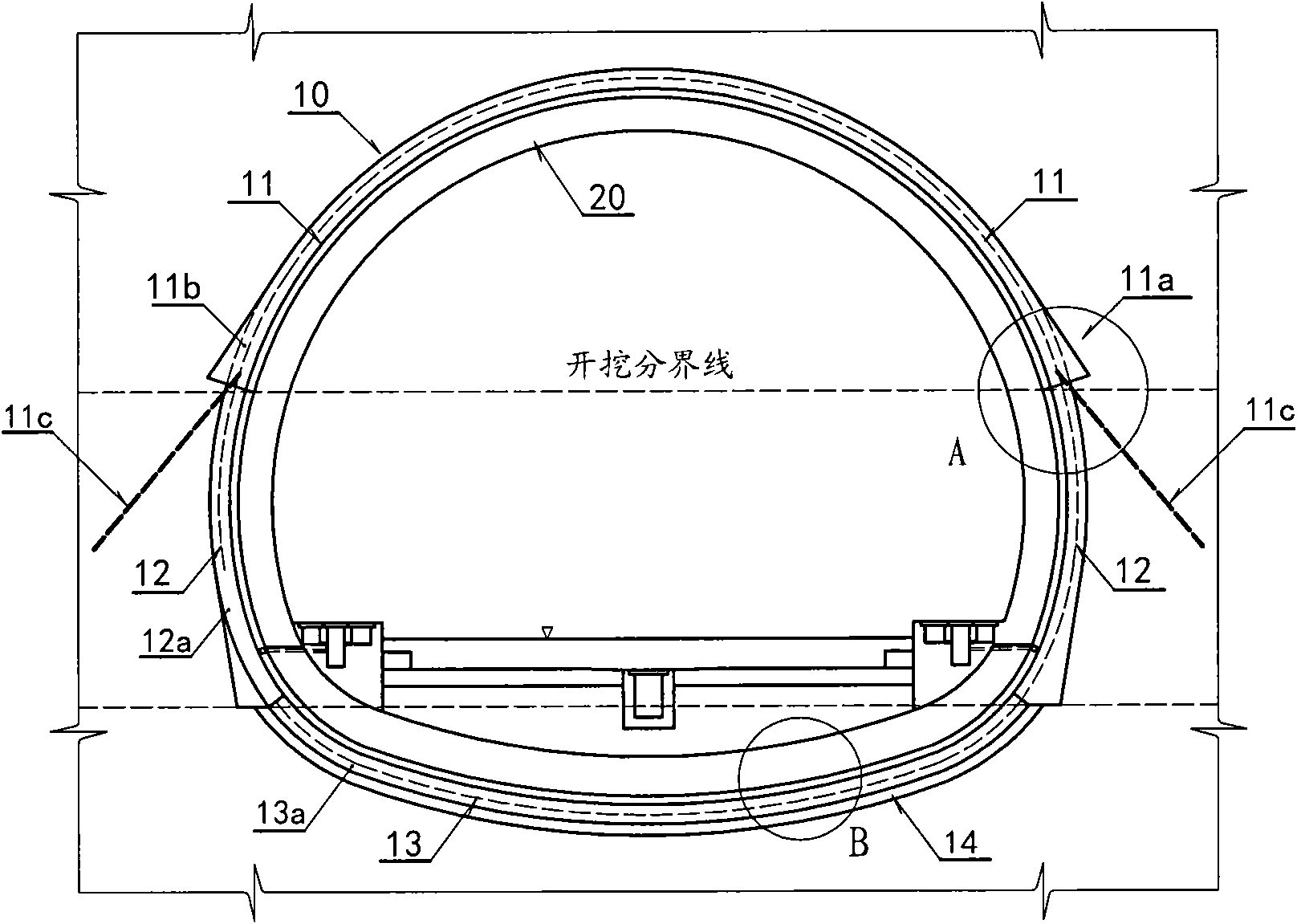

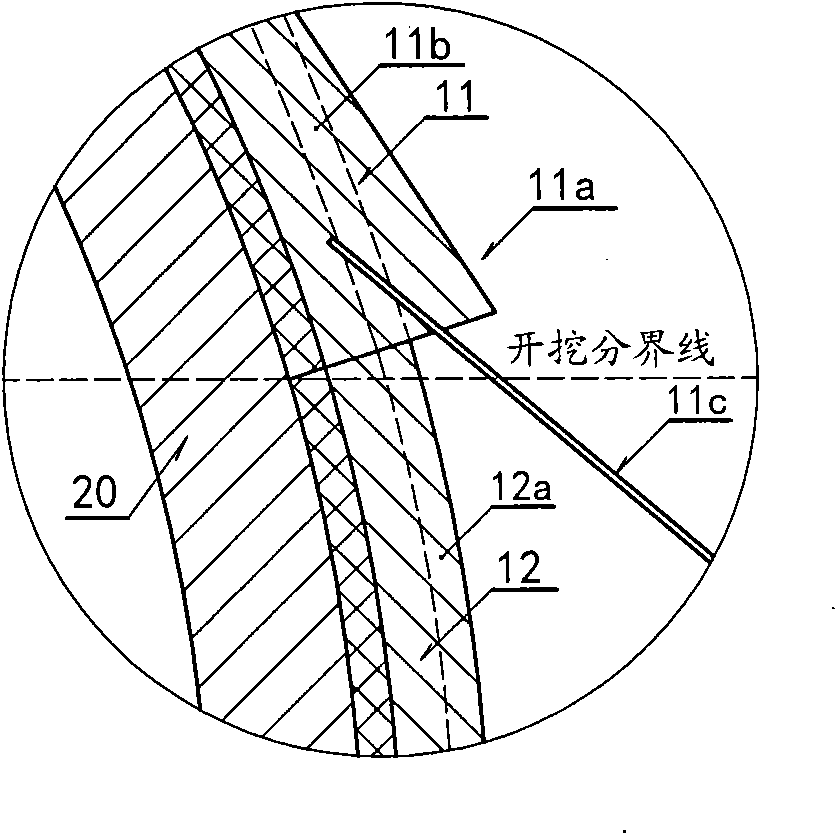

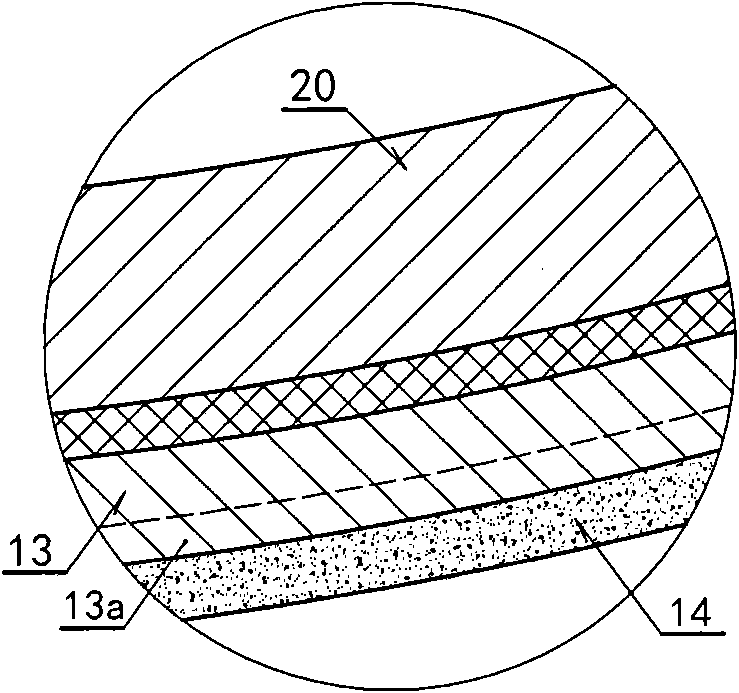

[0017] refer to figure 1 , The lining structure of the high-speed railway super-large section water-rich loess tunnel of the present invention includes an outer lining 10 and an inner lining 20, and the outer lining 10 is composed of a vault section 11, an arch wall section 12 and an inverted arch section 13 that seal the loess surrounding rock. refer to figure 2 , the arch foot portion 11a of the arch section 11 is widened laterally, and a circumferentially extending arch steel frame 11b is embedded in it, and the arch steel frame 11b is anchored to the loess surrounding rock by a locking foot bolt 11c. That is to say, after excavating the upper steps of the tunnel, the arch feet on both sides are respectively expanded to a certain width, and the steel frame 14 is erected, and after anchoring with the locking foot bolt 13, immediately spray concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com