Filtration-reducing agent for synthetic polymer oil-well cement

A technology for synthesizing polymers and oil well cement, which is applied in the field of polymers, and can solve the problems of sudden drop in polymer molecular weight, lack of hydrolytic stability, cement settlement and loss of water loss performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

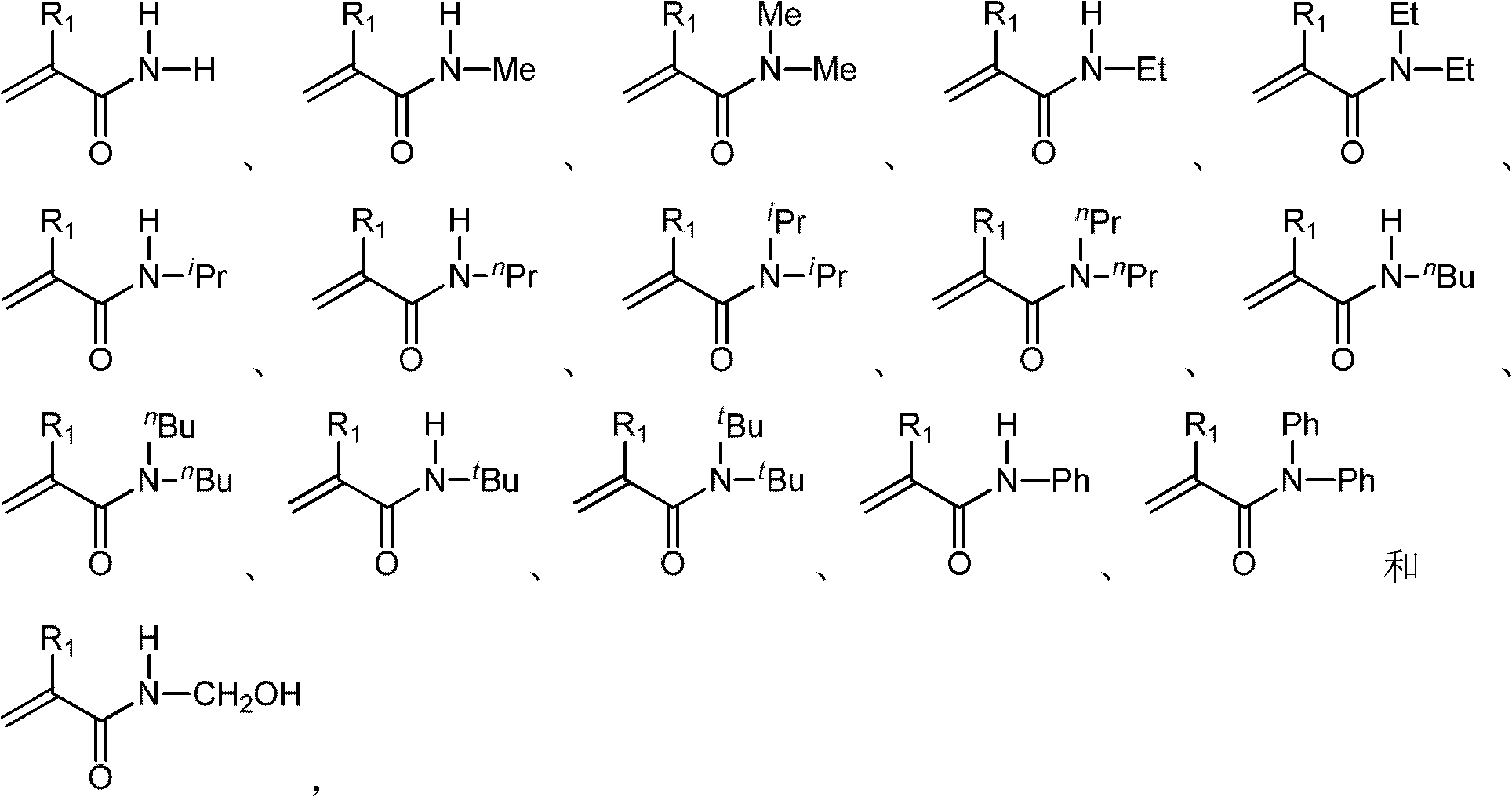

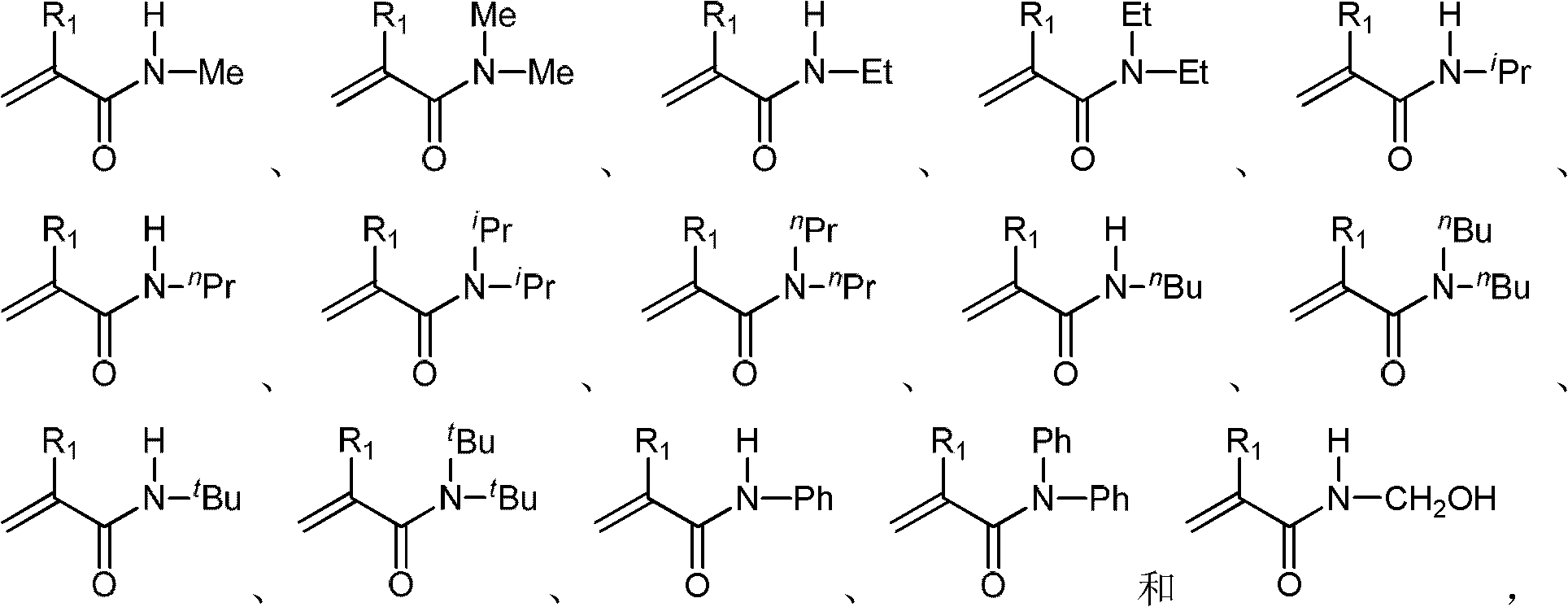

Method used

Image

Examples

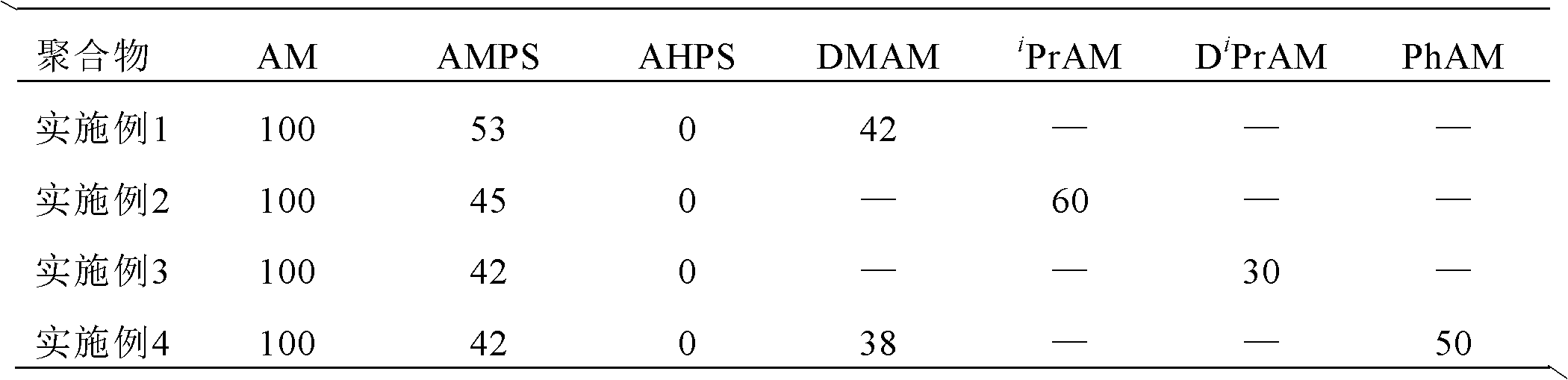

Embodiment 1

[0072] Example 1 Acrylamide / 2-acrylamide-2-methylpropanesulfonate / 3-allyloxy-2-hydroxyl-propanesulfonate / acrylic acid / N, N'-dimethylacrylamide (mol %: 22 / 27 / 16 / 13 / 22) Synthesis of Pentapolymer

[0073] Add 7.5g acrylamide, 59.4g sodium 2-acrylamide-2-methylpropanesulfonate (50% content), 10.5g N,N'-dimethylacrylamide, 4.5g acrylic acid, 0.2 g of N, N-methylenebisacrylamide and 30 g of water were stirred evenly as a crosslinking agent, and then put into a dropping funnel for later use.

[0074] 1.9g acrylamide, 14.8g sodium 2-acrylamide-2-methylpropanesulfonate (50% content), 52.3g sodium 3-allyloxy-2-hydroxyl-propanesulfonate (40% content) ), 1.1g of acrylic acid, 2.7g of N, N'-dimethylacrylamide and 80g of water were added to a flask with a heater and a stirring device, heated to 65°C under nitrogen protection, and then stirred for 180 minutes Evenly add the standby monomer mixture in the above dropping funnel dropwise, while adding dropwise, add 4.0g of 10wt% sodium persul...

Embodiment 2

[0075] Example 2 Acrylamide / 2-acrylamide-2-methylpropanesulfonate / 3-allyloxy-2-hydroxyl-propanesulfonate / acrylic acid / N-isopropylacrylamide (mol%: 25 / 25 / 14 / 15 / 21) Synthesis of Pentapolymers

[0076] Add 8.6g of acrylamide, 55.0g of sodium 2-acrylamide-2-methylpropanesulfonate (50% content), 5.2g of acrylic acid, 11.4g of N-isopropylacrylamide and 30g of water into a beaker and stir well Finally, put it into the dropping funnel and set aside.

[0077] 2.1g acrylamide, 13.7g sodium 2-acrylamide-2-methylpropanesulfonate (50% content), 45.8g sodium 3-allyloxy-2-hydroxyl-propanesulfonate (40% content ), 1.3g acrylic acid and 2.8g N-isopropylacrylamide, crosslinking agent 0.4g diallyl polyethylene glycol ether (molecular weight 500), and 60g water join in a flask with heater and stirring device , heated to 65°C under the protection of nitrogen, and then evenly added the spare monomer mixture in the dropping funnel dropwise within 180 minutes under stirring, while adding dropwise,...

Embodiment 3

[0078] Example 3 Acrylamide / 2-acrylamide-2-methylpropanesulfonate / 3-allyloxy-2-hydroxyl-propanesulfonate / acrylic acid / N, N-diisopropylacrylamide (mol %: 30 / 26 / 12 / 17 / 15) Synthesis of Pentapolymer

[0079] Add 10.2g acrylamide, 57.1g sodium 2-acrylamide-2-methylpropanesulfonate (50% content), 5.8g acrylic acid, 11.2g N,N-diisopropylacrylamide, Mix 1.0g sodium lauryl sulfate and 30g water evenly, put it into the dropping funnel, and set aside.

[0080] 2.6g acrylamide, 14.3g sodium 2-acrylamide-2-methylpropanesulfonate (50% content), 39.2g sodium 3-allyloxy-2-hydroxyl-propanesulfonate (40% content ), 1.5g acrylic acid, 2.8gN, N-diisopropylacrylamide, cross-linking agent pentaerythritol tetraallyl ether 0.8g (pentaerythritol tetraallyl ether, pentaerythritol triallyl ether and pentaerythritol diallyl ether mixture), 2.0g SDS and 80g water were added to a flask with a heater and a stirring device, heated to 65°C under nitrogen protection, and then evenly added dropwise to the spa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com