Mechanical mode and control blasting combined tunneling method

A technology for controlling blasting and tunnel excavation. It is used in tunnels, blasting, tunnel lining and other directions. It can solve the problems of difficulty and safety hazards, reduced flexibility, and high construction costs, and achieve the effects of reduced construction costs, less dust and lower prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, the method for excavating a tunnel by combining mechanical and controlled blasting according to the present invention will be described in detail with reference to the accompanying drawings.

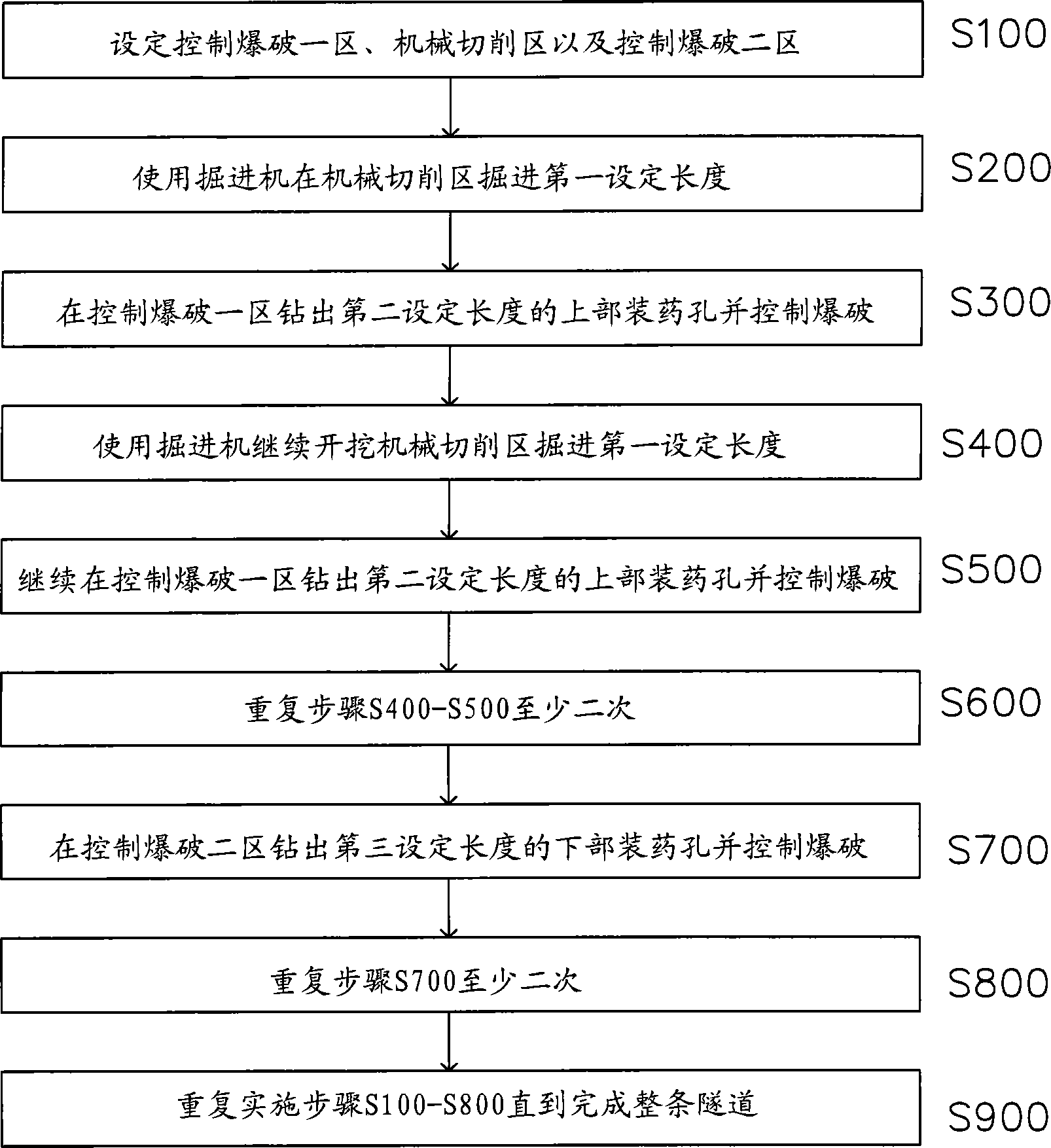

[0036] Please refer to Figure 1-Figure 3 , as a non-limiting example, the method for excavating a tunnel by combining mechanical and controlled blasting according to the present invention includes the following steps.

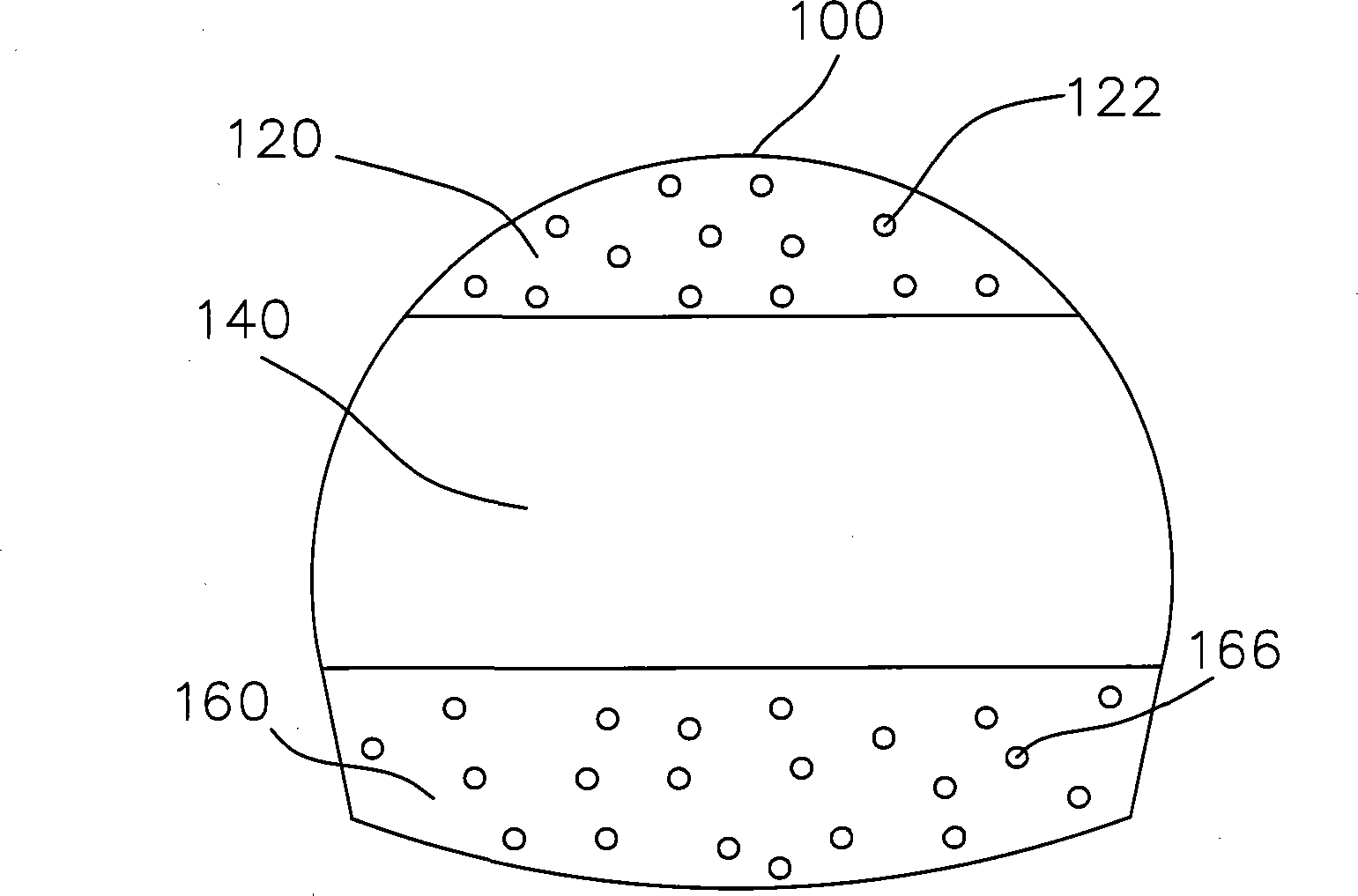

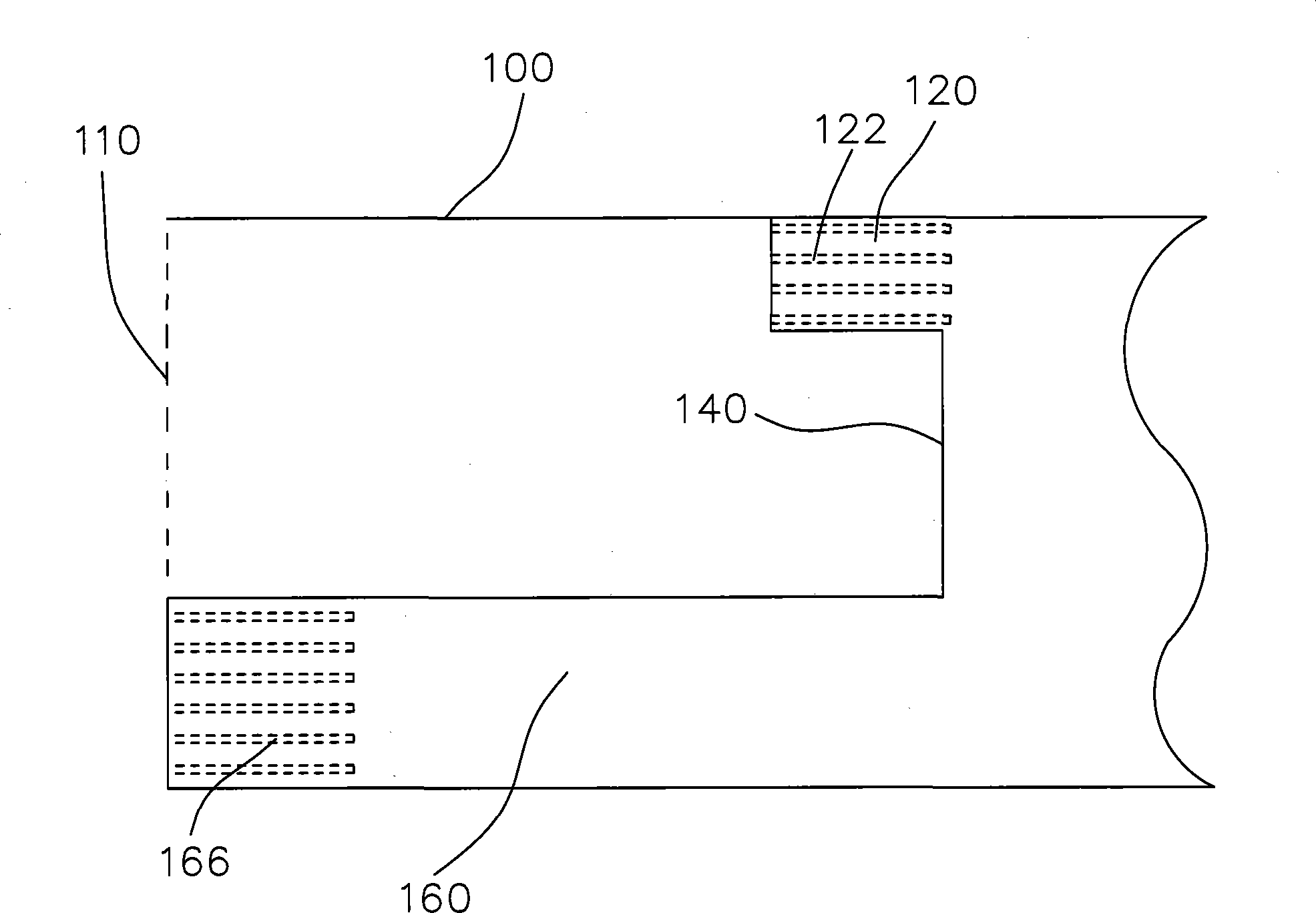

[0037] Step S100: Divide the tunnel 100 to be excavated (indicated by the tunnel excavation outline in the figure) from top to bottom into controlled blasting zone 1 120 , mechanical cutting zone 140 and controlled blasting zone 2 160 . Among them, the controlled blasting area 120 roughly corresponds to the vault area of the tunnel, the mechanical cutting area 140 roughly corresponds to the upper step area of the tunnel, and the controlled blasting area 160 roughly corresponds to the lower step area and the inverted arch area of the tunnel.

[0038] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com