Multi-node integral installation method for steel truss beam

A technology of overall installation and steel truss girders, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as high construction requirements, many construction nodes, and multi-section steel labor, so as to save construction period, speed up installation, The effect of ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

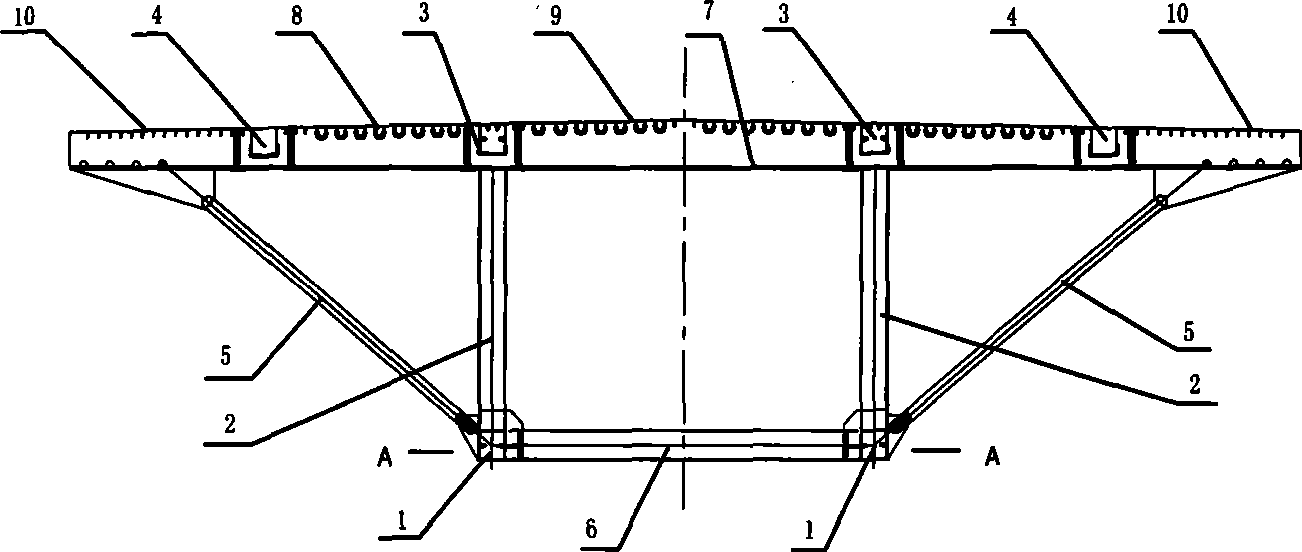

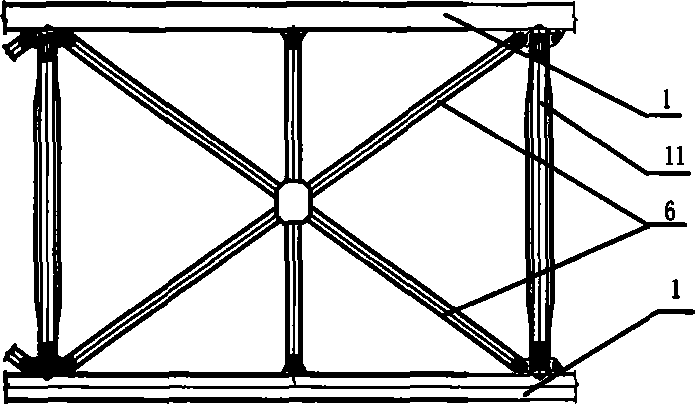

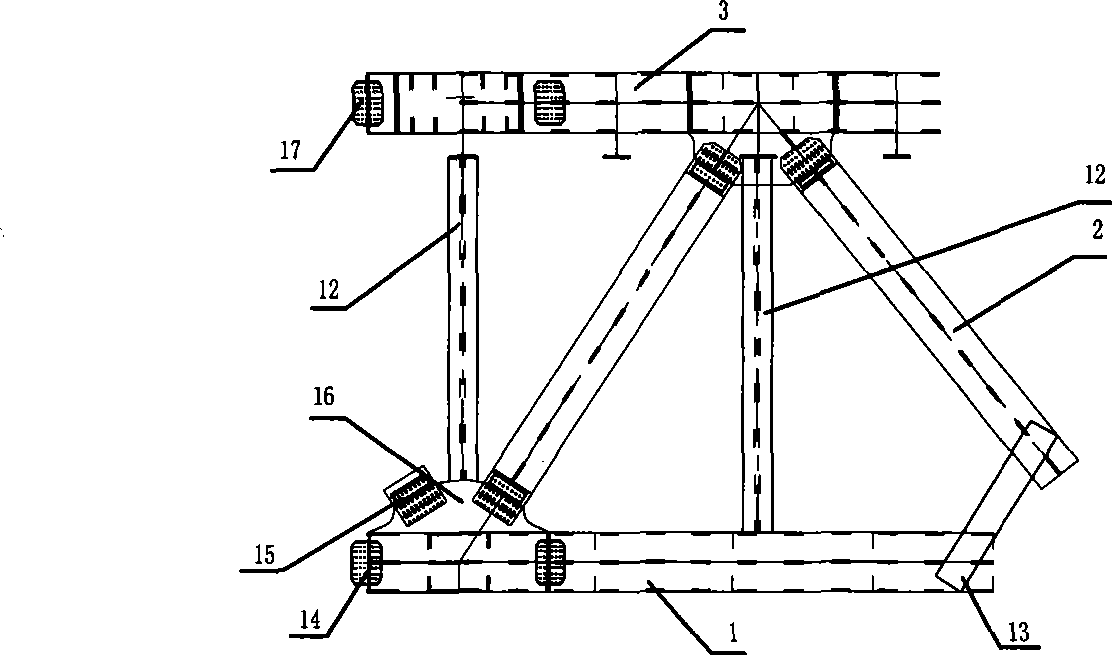

[0025] Below in conjunction with Chongqing Caiyuanba Yangtze River Bridge and with reference to the accompanying drawings, the present invention will be further described in detail.

[0026] A multi-node overall installation method for steel truss girders:

[0027] A. A standard section of steel truss girder is 16 meters long, consisting of lower chord 1, diagonal web 2, middle and upper chord 3, side upper chord 4, diagonal brace 5, lower beam 6, lower horizontal longitudinal joint 11, and bridge deck edge Block 8, bridge deck middle block 9, bridge deck side plate 10, and bridge deck beam 7 are assembled together to form a standard segment through joints at various points in the processing plant. In order to stabilize the structure of the standard segment, the A temporary vertical bar 12 is added in the middle of the oblique web bar 2 to connect with the lower chord 1, and the oblique web bar 2 to be docked is fixed with the temporary connecting plate 13 and the lower chord ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com