Karst-area underwater bridge pier drilled pile construction method

A construction method and technology of bored piles, which are applied in the direction of filling, drill bits, sheet pile walls, etc., can solve the problems of disproportionate economic benefits, inestimable total amount of grouting, and large karst caves, so as to reduce labor costs and ensure karst caves The effect of treatment effect and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

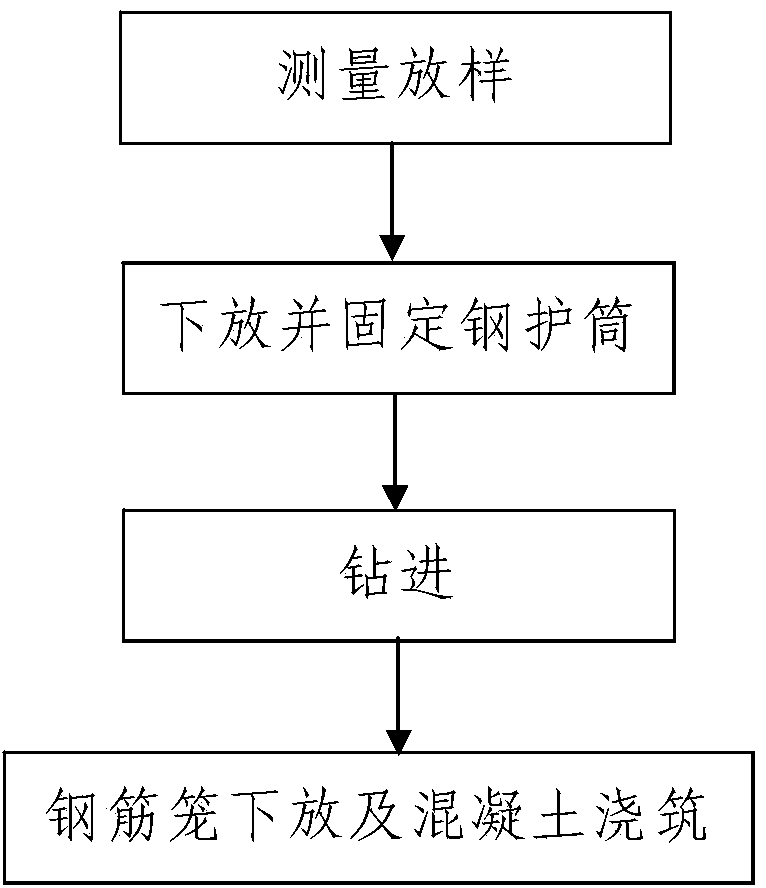

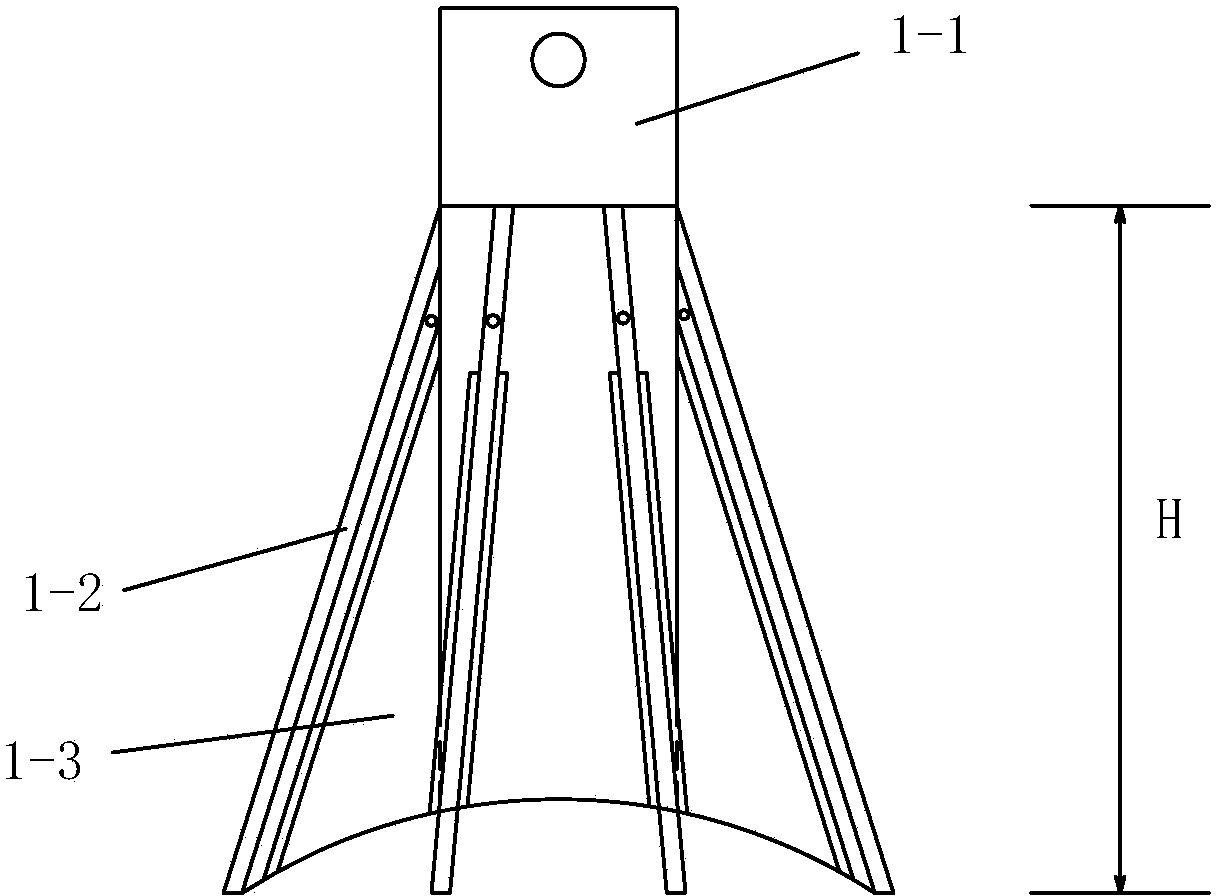

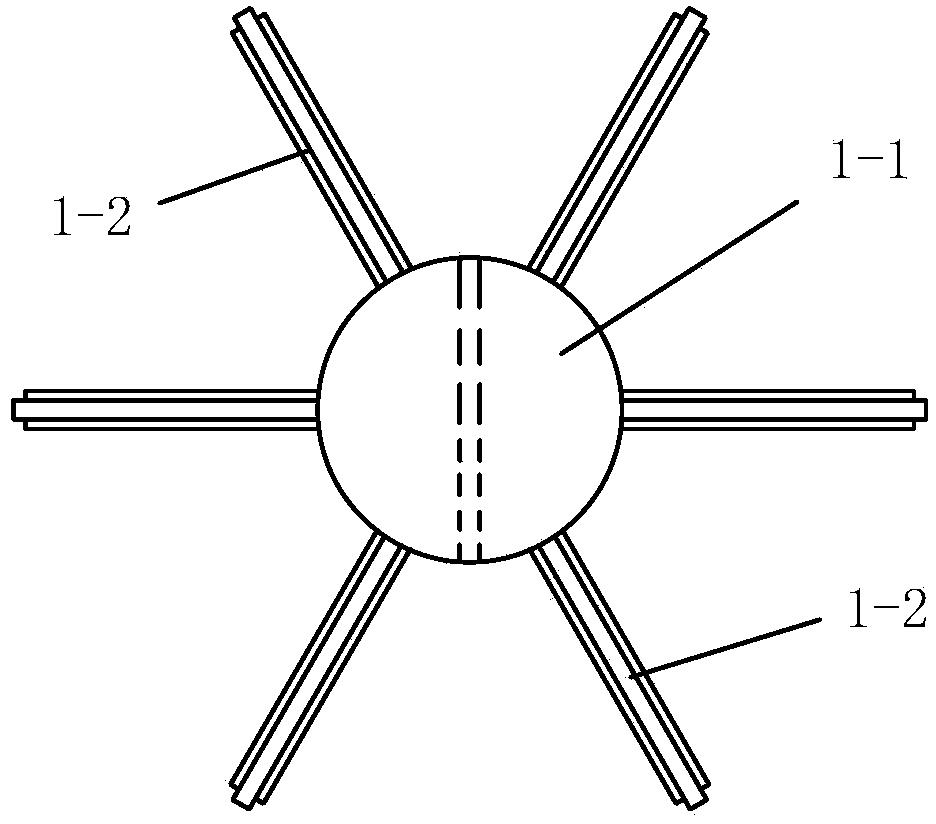

[0041] Such as figure 1 A method for constructing bored piles for piers in water for bridges in karst areas is shown. The constructed bored piles pass through one or more karst caves from top to bottom. The method includes the following steps:

[0042] Step 1. Measurement and stakeout: measure and stake out the pile positions of the currently constructed bored piles.

[0043] During actual construction, the measurement and setting out must be accurate, and the pile position deviation must meet the requirements. Lay out the wires as required. Once the piles are formed, if the pile position deviates greatly, the stress on some piles will change. The total station is used for laying out, repeated inspections during the laying out process, and compound multi-point control. Then correct the deviation to avoid large deviations, resulting in delays in the construction period and waste of funds.

[0044] After the completion of the survey and setting out, due to the extremely compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com