Shield/TBM online state monitoring system

A condition monitoring system and monitoring system technology, applied in measurement devices, instruments, etc., can solve the problems of occupation of testing personnel and equipment, secondary pollution of collected samples, and inability to collect data, so as to reduce the number and labor intensity, and avoid engineering The effect of risk occurrence and avoiding distortion of test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention is further explained in conjunction with the drawings and specific embodiments:

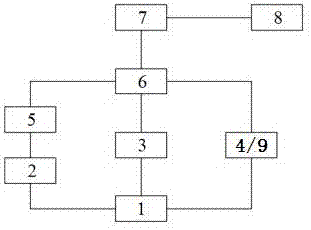

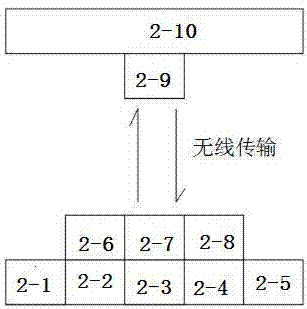

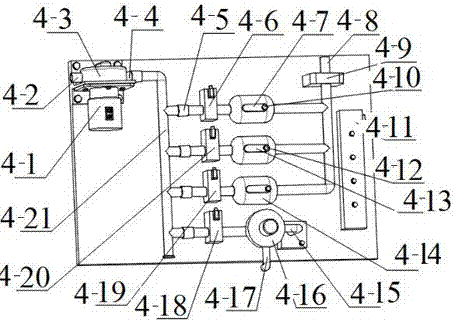

[0017] Such as figure 1 As shown, a shield / TBM online status monitoring system, the shield / TBM online status monitoring system has a mechanical signal acquisition instrument 2 and an oil parameter signal acquisition instrument; the mechanical signal acquisition instrument 2 is pasted on Multiple on the shield / TBM1; multiple mechanical signal acquisition devices 3 are corresponding to the hydraulic pump station, main propulsion cylinder, and shield settings; the mechanical signal acquisition device 3 corresponding to the hydraulic pump station is located in the connection between the motor and the hydraulic pump The mechanical signal acquisition device 3 corresponding to the main propulsion cylinder is located at the end of the main propulsion cylinder; the mechanical signal acquisition device 3 corresponding to the shield is located at the top, bottom and left and right ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com