Combined lining formwork trolley for subway station

A technology for subway stations and formwork trolleys, applied in shaft linings, tunnel linings, underground chambers, etc., can solve the problems of large space occupation, poor use effect, and low construction efficiency, and achieve safe use, good integrity, and The effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

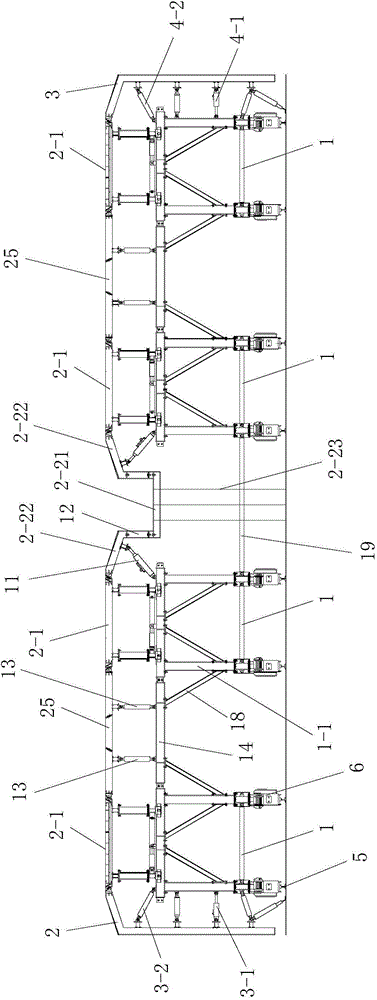

[0089] In this example, if image 3 As shown, the difference from Embodiment 1 is: between the first trolley and the trolley support top template 2-1 installed on the second trolley and between the third trolley and the fourth trolley The trolley support top formwork 2-1 installed on the trolley is connected through the grooved combined formwork, and the lower part of the first vertical formwork segment in the grooved combined formwork is passed through the first The two vertical formwork sections 12 are connected to the bottom connection formwork 2-21; the assembled formwork 25 is passed between the second trolley and the trolley support top formwork 2-1 mounted on the third trolley to connect.

[0090] In this embodiment, the structures and connections of other parts are the same as those in Embodiment 1.

Embodiment 3

[0092] In this example, if Figure 4 As shown, the difference from Embodiment 1 is that in this embodiment, the number of the longitudinally moving trolleys 1 is 5, that is, N=4. The 5 longitudinally moving trolleys 1 are respectively the first from left to right. One car, second car, third car, fourth car and fifth car. That is to say, the first trolley is the left trolley, and the fifth trolley is the right trolley. Between the first trolley and the trolley support top formwork 2-1 installed on the second trolley and between the fourth trolley and the trolley support top formwork installed on the fifth trolley 2-1 are connected through the single formwork 24, the second trolley and the trolley mounted on the third trolley support the top formwork 2-1 and the third trolley It is connected with the trolley support top formwork 2-1 installed on the fourth trolley through the grooved combined formwork, and the first vertical formwork section in the grooved combined formwork T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

| Horizontal width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com