Foundation strengthening treatment method

A technology of foundation reinforcement and flushing holes, which is applied in infrastructure engineering, soil protection, construction, etc., to achieve the effects of ensuring safety, reducing engineering costs, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described by the following examples. This example is only used to further illustrate the present invention, but it cannot be interpreted as limiting the protection scope of the present invention. Essential improvements and adjustments belong to the protection scope of the present invention.

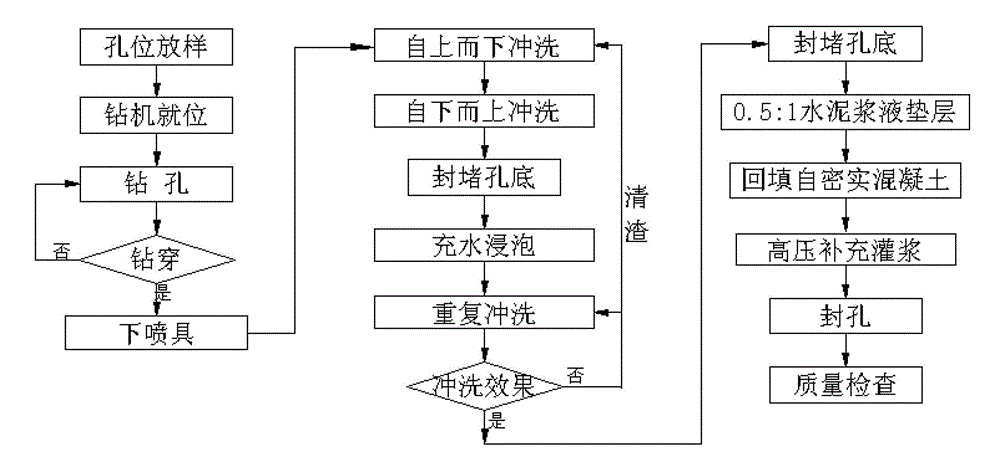

[0027] to combine figure 1 , figure 1 It is the technical process of the method of the present invention. Ground stabilization treatment techniques including drilling, flushing, backfilling, high pressure supplementary grouting and quality inspection steps.

[0028] (1) drilling

[0029] The drilling diameter of the main flushing hole is not less than φ300mm. The formation of the flushing channel can be formed by drilling from low elevation to high elevation, or from high elevation to low elevation. The direction of the hole can refer to geological survey data or actual drilling The slag return situation is determined, and the azimuth and apex a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com