Electrochemical method of oil removal of wastewater produced in oil extraction by polymer flooding displacement

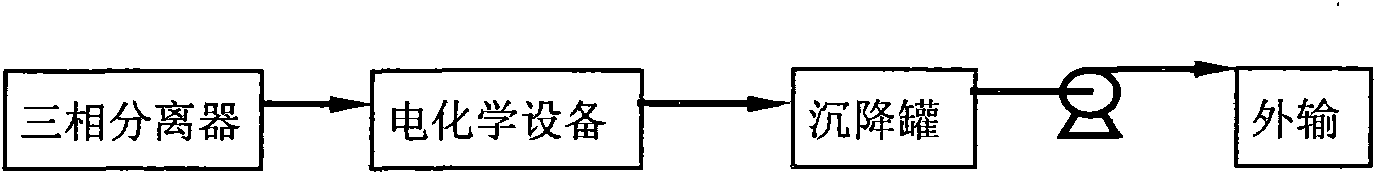

An oily sewage and polymer technology is applied in the electrochemical field of polymer flooding oil production sewage degreasing, which can solve the problems of unsuitable popularization and high cost, and achieve the effects of easy popularization and application, simple operation, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

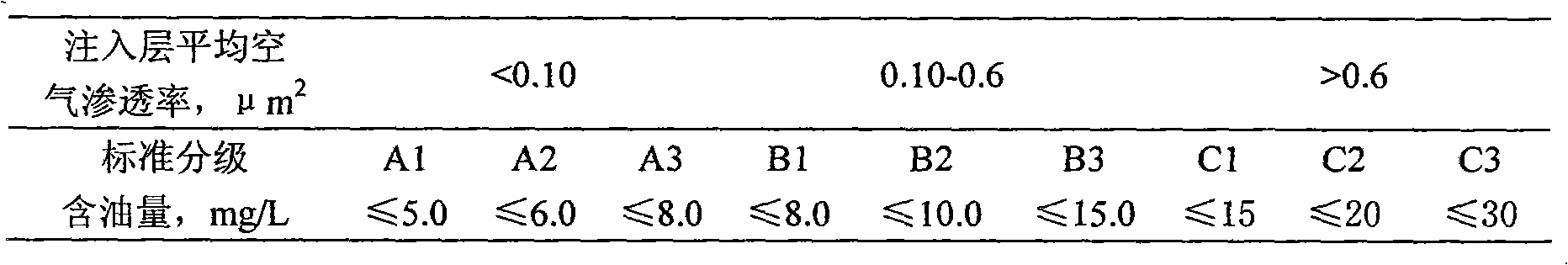

[0029] The scale of polymer flooding oil production sewage treatment in the oilfield sewage station is 238m 3 / h, using electrochemical methods for degreasing and purification treatment, the results of the three tests are shown in Table 2. Introduce unidirectional continuous direct current into the polymer flooding oil production sewage, the distance between each pair of cathode and anode electrodes is 0.50 mm, the anode is coated and sintered ruthenium, rhodium, iridium oxide on metal titanium, and the cathode material is stainless steel. The voltage between the negative and positive electrodes is 1V, the current is 9600A, and the current density is 50A / m 2 , the total electrode area is 192m 2 . All electrodes are divided into 10 groups, each group has 60 pairs of electrodes, a total of 600 pairs of electrodes. The electrodes in each group are connected in parallel, and the electrodes in each group are connected in series.

[0030] During the electrolysis process of polym...

Embodiment 2

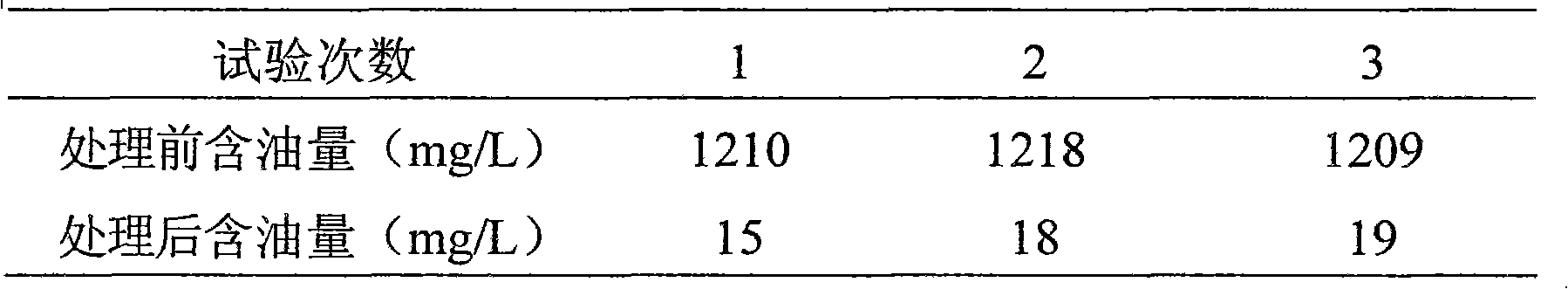

[0035] The scale of polymer flooding oil production sewage treatment in the oilfield sewage station is 238m 3 / h; The electrochemical method was used for oil removal and purification treatment, and the results of the three tests are shown in Table 3. Into the polymer flooding oil production sewage into regular diverted continuous direct current, the anode is graphite, the cathode material is titanium, the distance between each pair of cathode and anode electrodes is 15 mm, the voltage between each pair of cathode and anode electrodes is 20V, and the current is 9600A, the current density is 1000A / m 2 , the total electrode area is 9.6m 2 , 30 pairs of electrodes connected in parallel.

[0036] Table 3 Example 2 Experimental Results

[0037]

[0038] It can be seen from Table 3 that the oil content in the treated sewage is less than 30mg / L, which can basically meet the oil content requirements of reinjected sewage.

Embodiment 3

[0040] The scale of polymer flooding oil production sewage treatment in the oilfield sewage station is 238m 3 / h; The electrochemical method was used for oil removal and purification treatment, and the results of the three tests are shown in Table 4. Introduce unidirectional pulsed direct current into the polymer flooding oil production sewage, the voltage between each pair of cathode and anode electrodes is 5.12V, the current is 9600A, 10 pairs of electrodes are connected in parallel, and the total electrode area is 3.2m 2 , the current density is 3000A / m 2 , the distance between each pair of cathode and anode electrodes is 50 mm, the gap between each pair of cathode and anode electrodes is filled with fast ion conductors, the anode is conductive ceramics, and the cathode material is conductive film.

[0041] Table 4 Example 3 Experimental Results

[0042]

[0043] The experimental data in Table 4 shows that the oil content in the treated sewage is less than 30 mg / L, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com