Steel structure building construction method for one-step pre-burying of foundation bolts

An anchor bolt and construction method technology, which is applied in construction, building structure, construction material processing and other directions, can solve the problems such as non-reusable, difficult to guarantee the pre-embedded accuracy of anchor bolts, and difficult to guarantee the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

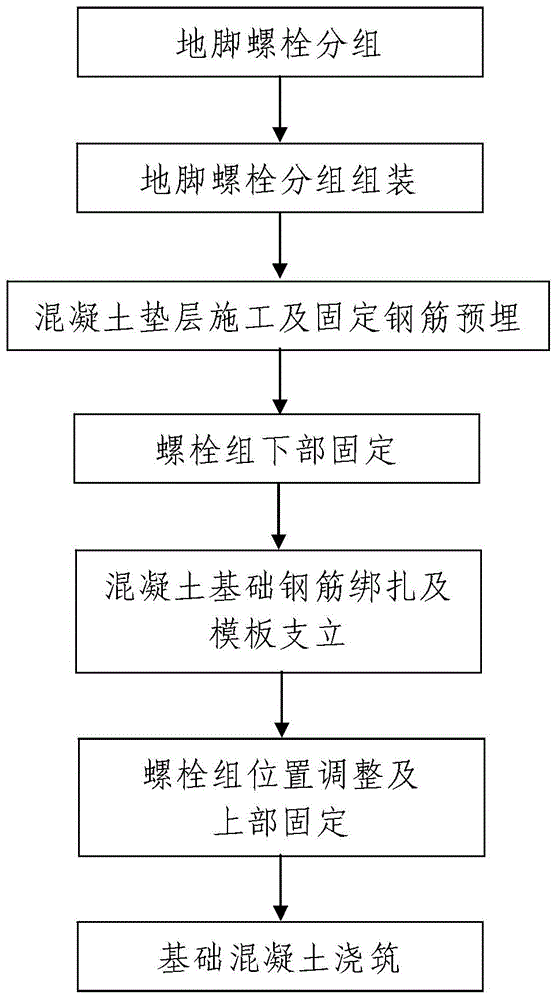

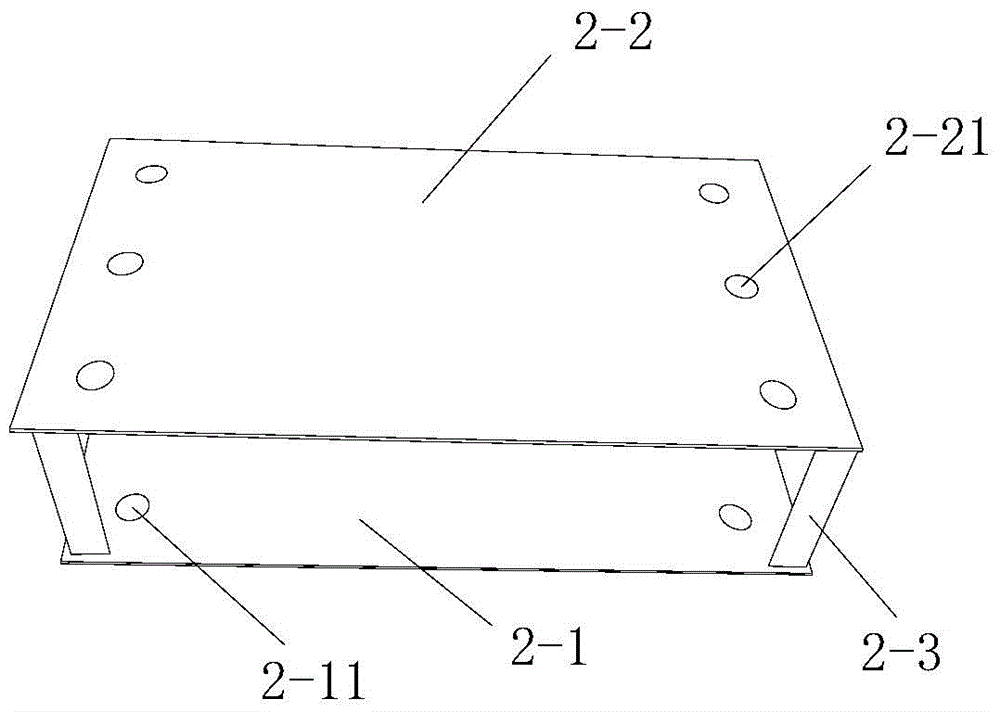

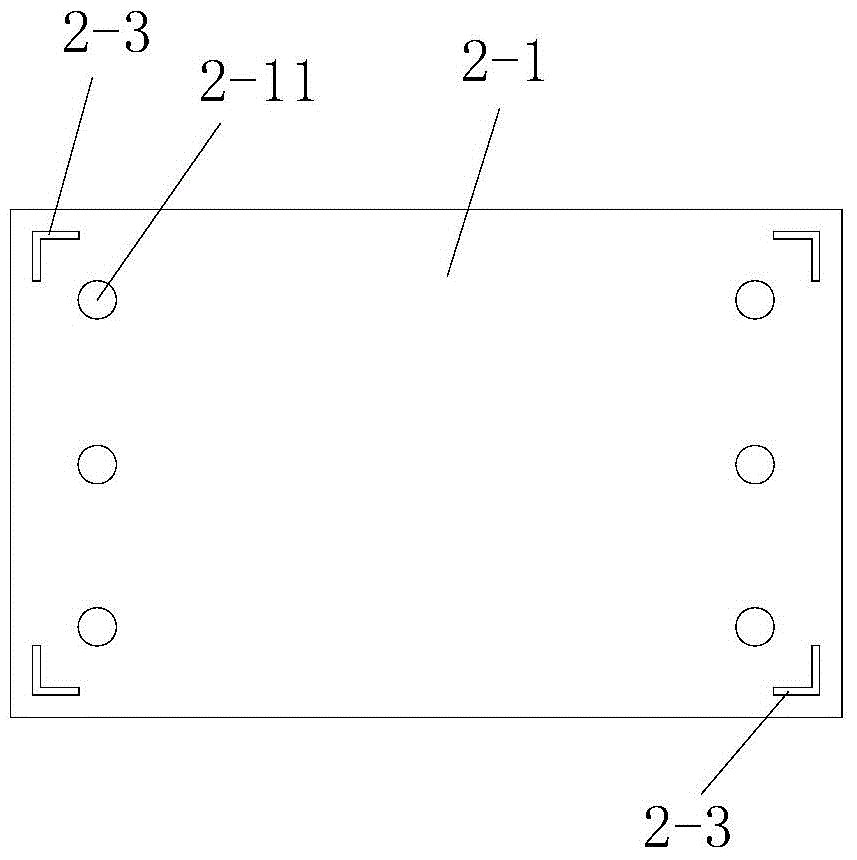

[0057] Such as figure 1 The shown one-time construction method of pre-embedded anchor bolts in steel structure buildings, the number of pre-embedded anchor bolts 1 is N, and the N anchor bolts 1 are all buried in the concrete foundation of the steel structure building to be constructed Inside, the diameters of the N anchor bolts 1 are not greater than 50mm and they are arranged vertically, wherein N is a positive integer and N≥4. A layer of concrete cushion is arranged at the bottom of the concrete foundation, and both the concrete foundation and the concrete cushion are arranged horizontally. The concrete foundation is a reinforced concrete structure and a reinforcement cage is arranged inside it. When constructing a plurality of said anchor bolts 1, the process is as follows:

[0058] Step 1. Grouping of anchor bolts: According to the embedding positions of the N anchor bolts 1 in the concrete foundation, the N anchor bolts 1 are divided into M groups, and the anchor bolts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com