Modified thixotropic slurry and preparation method thereof

A technology of thixotropic mud and preparation method, which is applied in the field of thixotropic mud and can solve the problems such as the inability to effectively combine the surrounding soil and the inability to form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

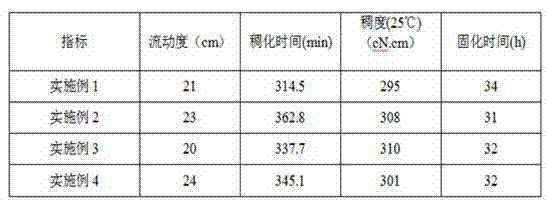

Embodiment 1

[0085] A modified thixotropic mud comprising the following components in parts by mass:

[0086] Sodium bentonite with a colloidal value of 90-100 100

[0087] water 1100

[0089] Lime paste 100

[0090] Polyacrylamide 0.8

[0091] Ferric silicate sulfate 0.8

[0092] Aluminum chloride 0.4

[0093] Glucose 2

[0094] Sodium rosinate 0.4.

[0095] According to the proportion of the above-mentioned modified thixotropic mud, it is prepared as follows:

[0096] (1) Add 1056 parts of water into the mixing tank;

[0097] (2) Slowly add bentonite into the mixing tank and stir evenly;

[0098] (3) Dissolve sodium carbonate with 40 parts of water to obtain sodium carbonate solution, then add sodium carbonate solution into the mixing tank, stir evenly, then add flocculant and stir evenly to obtain ordinary thixotropic mud;

[0099] (4) Dissolve the retarder with 4 parts of water, and stir well to obtain the retarder solution;

[0100] (5) Add the r...

Embodiment 2

[0103] A modified thixotropic mud comprising the following components in parts by mass:

[0104] Sodium bentonite with a colloidal price of 80-90 100

[0105] water 980

[0106] Sodium carbonate 9.5

[0107] Lime paste 90

[0108] Polyacrylamide 0.6

[0109] Ferric silicate sulfate 0.6

[0110] Aluminum chloride 0.3

[0111] Glucose 1.6

[0112] Sodium rosinate 0.3.

[0113] According to the proportion of the above-mentioned modified thixotropic mud, it is prepared as follows:

[0114] (1) Add 953 parts of water into the mixing tank;

[0115] (2) Slowly add bentonite into the mixing tank and stir evenly;

[0116] (3) Dissolve sodium carbonate with 19 parts of water to obtain a sodium carbonate solution, then add the sodium carbonate solution into the mixing tank, stir evenly, then add flocculant and stir evenly to obtain ordinary thixotropic mud;

[0117] (4) Dissolve the retarder with 8 parts of water, and stir well to obtain the retarder solution;

[0118] (5) Add t...

Embodiment 3

[0121] A modified thixotropic mud comprising the following components in parts by mass:

[0122] Sodium bentonite with a colloidal price of 70-80 100

[0123] water 920

[0124] Sodium carbonate 12.5

[0125] Lime paste 75

[0126] Polyacrylamide 0.4

[0127] Ferric silicate sulfate 0.4

[0128] Aluminum chloride 0.2

[0129] Glucose 1.0

[0130] Sodium rosinate 0.25.

[0131] According to the proportion of the above-mentioned modified thixotropic mud, it is prepared as follows:

[0132] (1) Add 862 parts of water into the mixing tank;

[0133] (2) Slowly add bentonite into the mixing tank and stir evenly;

[0134] (3) Dissolve sodium carbonate with 50 parts of water to obtain sodium carbonate solution, then add sodium carbonate solution into the mixing tank, stir evenly, then add flocculant and stir evenly to obtain ordinary thixotropic mud;

[0135] (4) Dissolve the retarder with 8 parts of water, and stir well to obtain the retarder solution;

[0136] (5) Add the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com