Tunnel underground river water burst blockage construction method

A technology of underground river gushing and construction method, applied in the field of tunnel engineering, can solve the problems of personal accident, high cost, difficult handling, etc., and achieve the effect of ensuring the construction period, reducing the construction cost and improving the construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

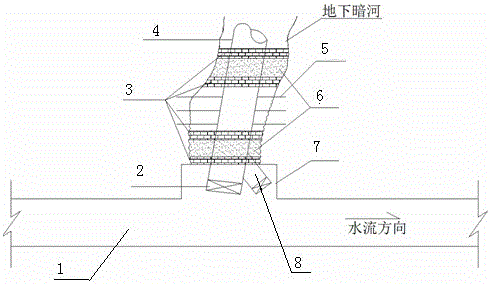

[0017] In the first step, the intersection of the underground river and the diversion tunnel 1 is expanded and excavated to 3.5m×2m, so that the valve can be installed, and the valve will not encroach on the size of the concrete lining of the diversion tunnel after installation. At the same time, inserting ribs 5 are arranged circumferentially on the cave wall above the water surface line of the underground river. The inserting ribs are Φ25mm, and the insertion length is 2m into the rock for 1.7m. , as the anchor point of the diversion steel pipe.

[0018] The second step is to install the diversion steel pipe. The diversion steel pipe 4 is a steel pipe with an inner diameter of 600mm and a wall thickness of 4mm. The length of the diversion steel pipe is 7.5m. Gate valve 2. The bottom of the diversion steel pipe is 30cm away from the water surface line of the underground river, and the diversion steel pipe is transported to the installation working surface in sections, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com