Fence linkage block and production process thereof

A production process and technology of interlocking blocks, which is applied in the field of dam fence interlocking blocks, can solve the problems that the quality, quantity, strength and construction quality of block stones cannot meet the design requirements, and cannot meet the safety of dam slopes, etc. The effect of easy quality control, easy construction quality assurance and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

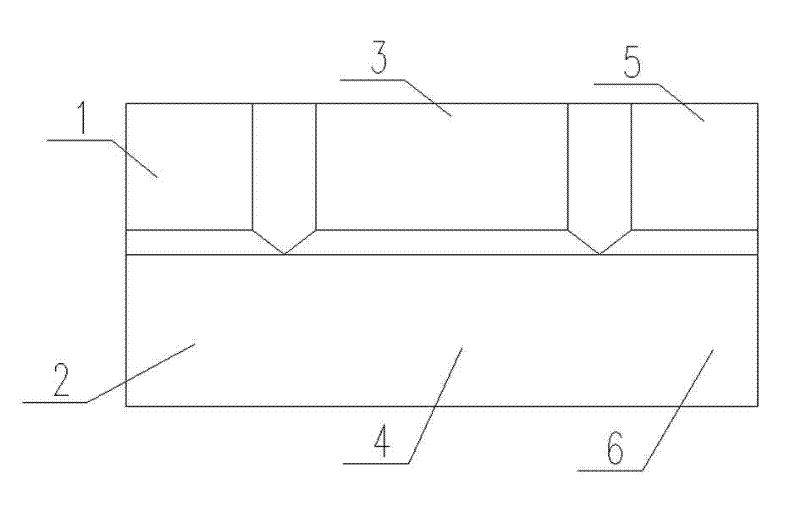

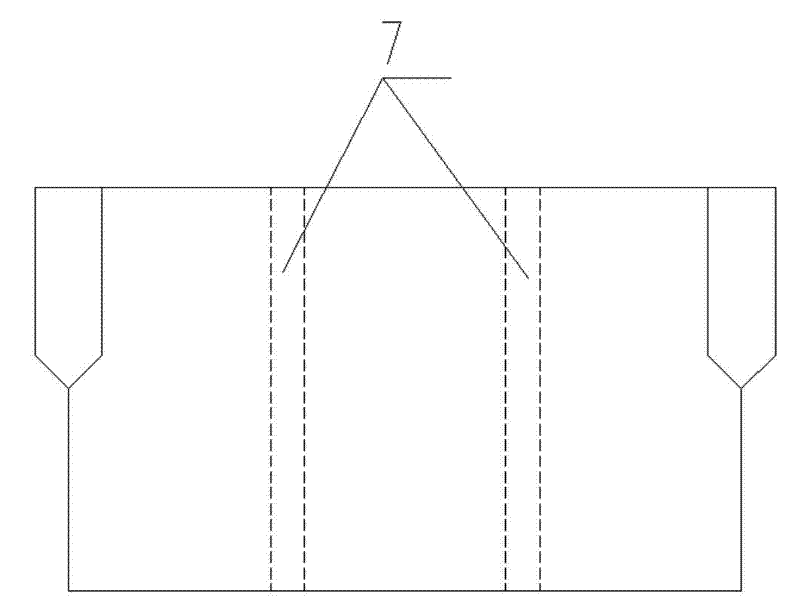

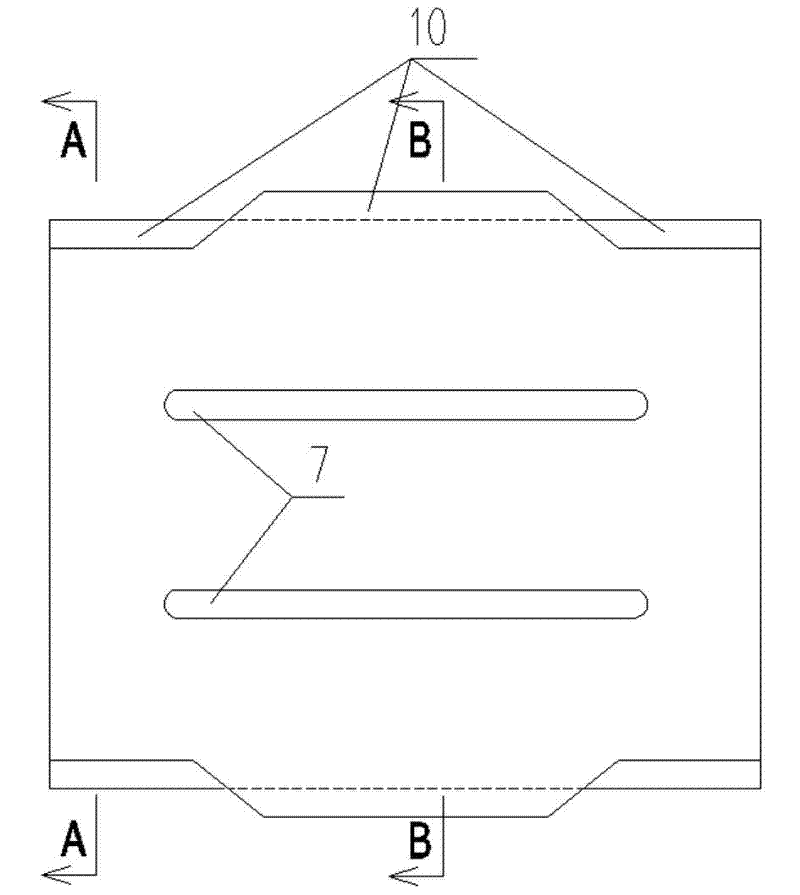

[0034] Embodiment 1: as figure 1 As shown in -8, the fence interlocking block, the outline of the fence interlocking block is a rectangular block, the left and right two symmetrical sides are planes, the front and rear two symmetrical sides are interlocking planes, the bottom surface is a plane, and the top surface is a plane; the fence interlocking block The block is provided with permeable fence water-permeable strip holes 7 from the top surface to the bottom surface; the interlocking surface includes a middle section and two end sections, the middle section is the upper part 3 convex and the lower part 4 concave / the upper part 3 concave and the lower part 4 convex, and the two end sections are the upper part 1 , 5 concave lower part 2, 6 convex / upper part 1, 5 convex lower part 2, 6 concave, the length of each section of the two end sections is 1 / 2 of the length of the middle section, and the corresponding middle section and two end sections on the same level The concav...

Embodiment 2

[0037] Embodiment 2, as Figure 9 As shown in -16, the difference from Example 1 is that the top surface of the fence interlocking block is a plane with roughening 8, and the roughening 8 is a protrusion arranged on the front side or rear side of the top of the fence interlocking block near the edge platform. Figure 11 In 11 places, protrusions and grooves appear alternately in the width and thickness directions, with the same shape, which are used for spatial interconnection, increasing stability and flood resistance.

[0038]The production process of the above-mentioned fence interlocking blocks includes molds that match the shape of the above-mentioned fence interlocking blocks. The production steps are: (1) selection and proportioning of concrete raw materials, viber consistency of 15-30s, and water-cement ratio of 0.40-0.45 , the sand rate is 35-40%; the cement is PO42.5 ordinary Portland cement, the coarse aggregate is crushed stone with a particle size between 5-10mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com