Construction method for reverse construction of continuous wall encountering underground pipeline

A technology of underground pipelines and construction methods, which is applied in the field of construction, can solve the problems that the enclosure structure cannot be constructed normally, and achieve the effect of saving relocation costs and ensuring the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

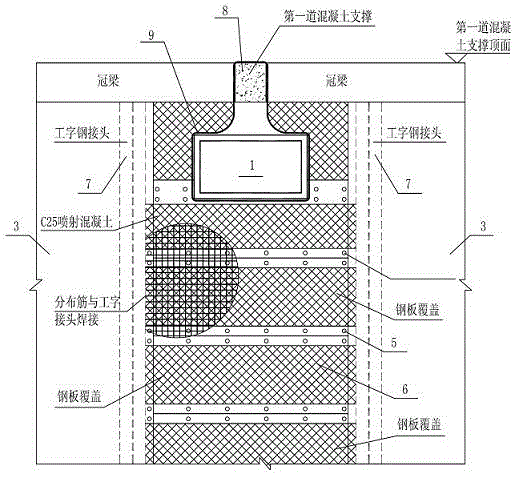

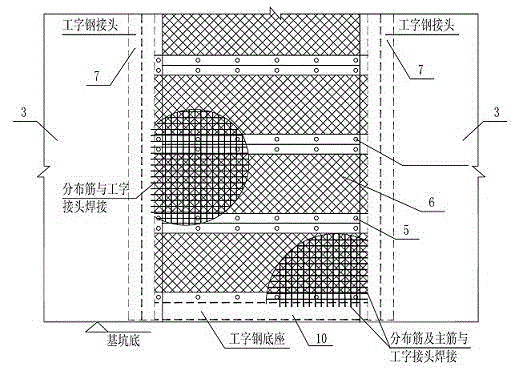

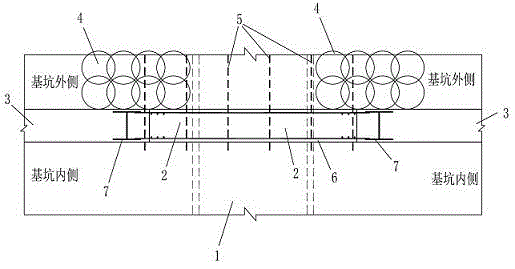

[0017] A construction method of the present invention for the reverse construction of a continuous wall when encountering an underground pipeline is: please refer to the plane image 3 , also known as the top view, which shows that when the diaphragm wall encounters the underground pipeline and the pipeline is difficult to relocate, in order to ensure the construction period, the design of the diaphragm wall in the pipeline range is adopted in the reverse form. First, according to the plane position of the pipeline 1 and the relationship between the pipeline 1 and the enclosure structure, the width of the inverse continuous wall 2 is determined. After the range of the inverse diaphragm wall 2 is determined, the wall width of the adjacent normal section diaphragm wall 3 is adjusted, and the adjacent diaphragm wall adopts the section steel joint 7; 3. Then, two rows of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com