Loess strata subway tunnel earth pressure balance shield construction method

A technology of earth pressure balance shield tunneling and construction methods, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as difficult selection of shield machines, various types of loess strata, and deformation of loess strata, etc., to achieve Good synchronous grouting effect, effective ground settlement, and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

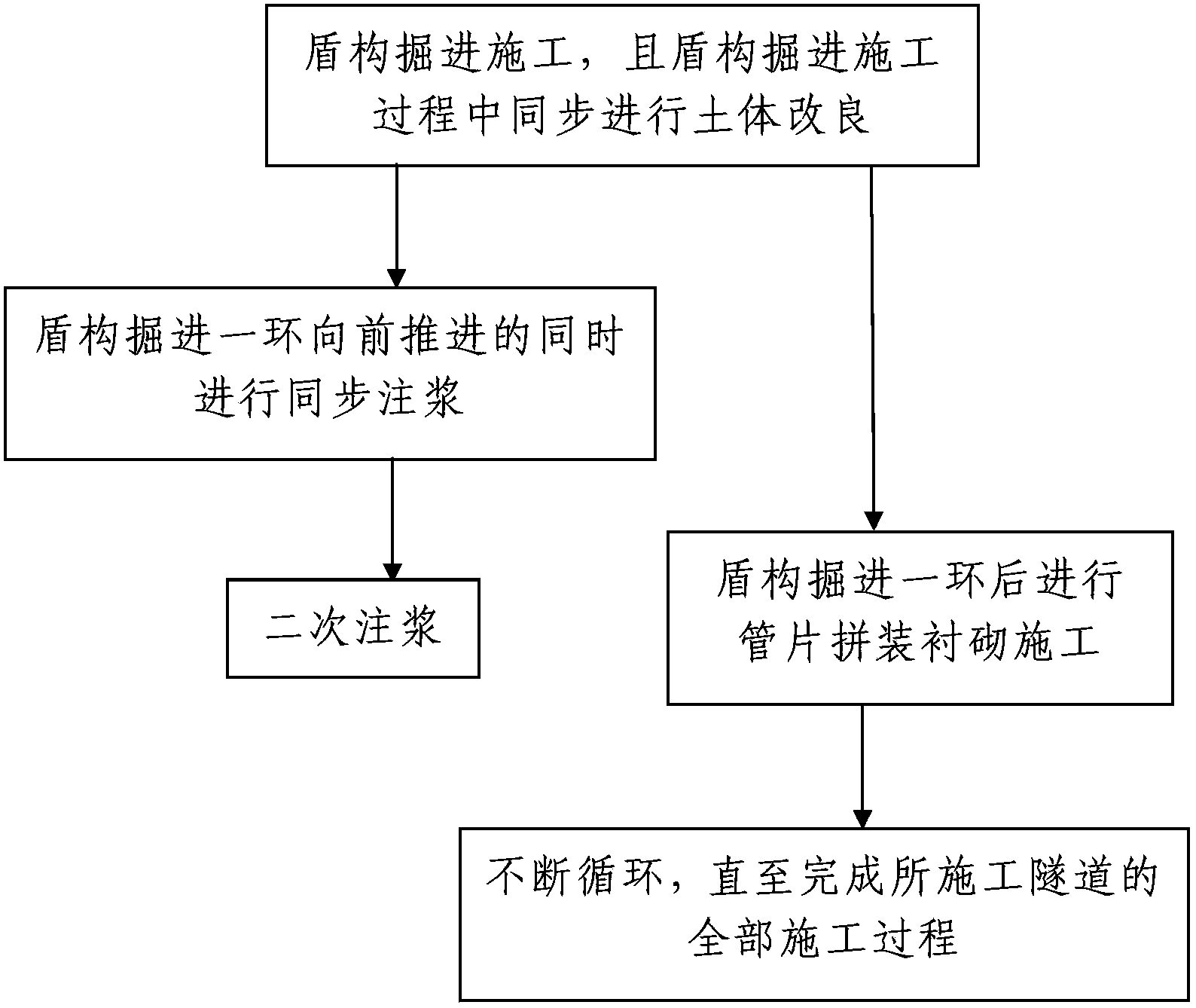

[0034] like figure 1 A method for constructing an earth pressure balance shield for a loess stratum subway tunnel shown, is characterized in that the method comprises the following steps:

[0035] Step 1. Shield tunneling construction: use an earth pressure balance shield machine to carry out shield tunneling construction on the constructed subway tunnel from front to back. During the shield tunneling construction process, the construction quality of shield spiral unearthing, shield tail sealing, synchronous grouting and secondary grouting shall be strictly controlled.

[0036] During shield excavation construction, the excavation speed is not greater than 10cm / min, the thrust of the earth pressure balance shield machine during excavation (referring to the total thrust of the shield machine) is not greater than 15000KN, and the earth pressure balance shield machine The internal pressure of the soil silo is maintained at 1 bar to 2 bar; the cutter head of the earth pressure ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com