Patents

Literature

35results about How to "Avoid crushed situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

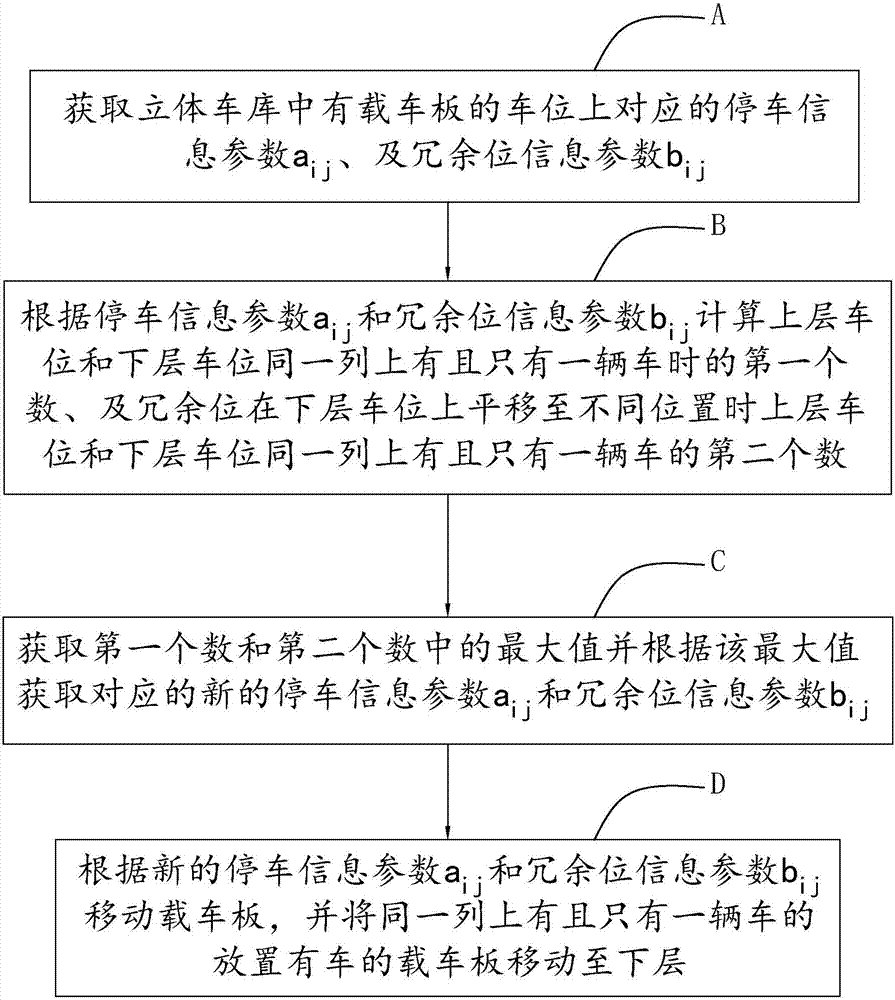

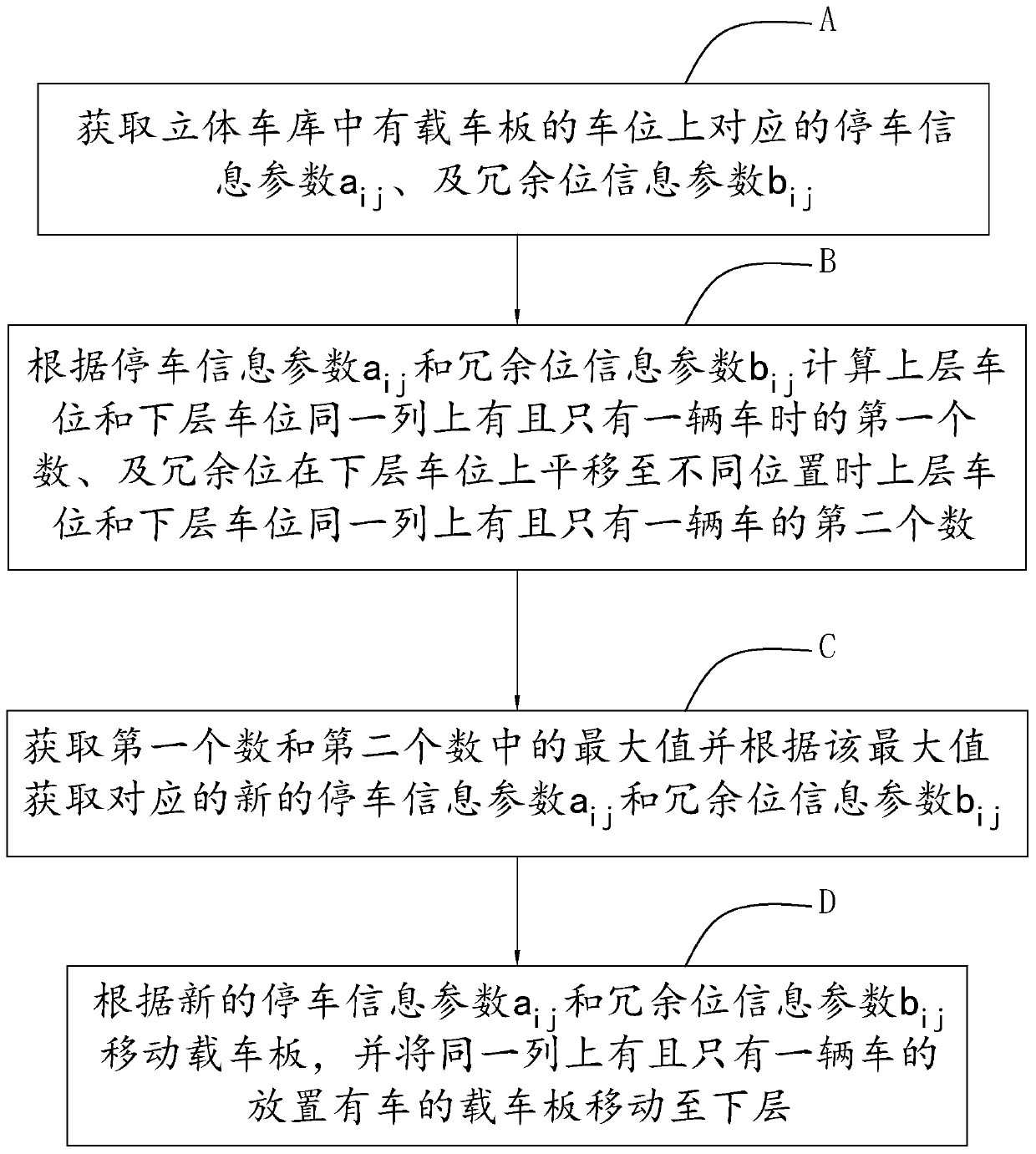

Two-layer up and down going and transversely moving type stereo garage vehicle pick-up peak hour management method

ActiveCN107256403AImprove pick-up efficiencyAvoid misuseDetection of traffic movementIndication of parksing free spacesComputer science

Owner:SHANGHAI CHANGYUE AUTOMATION MACHINERY

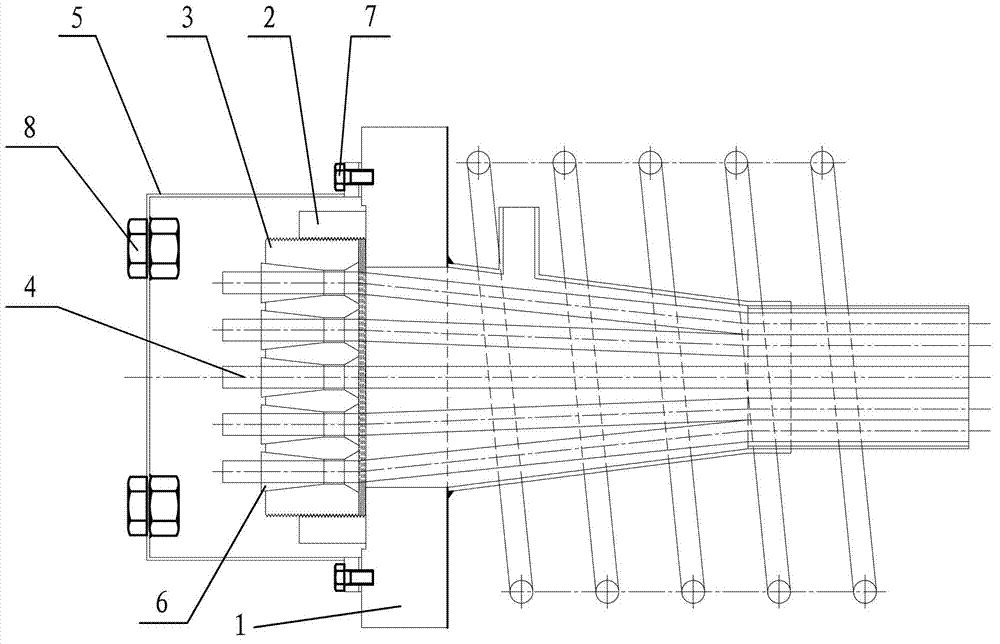

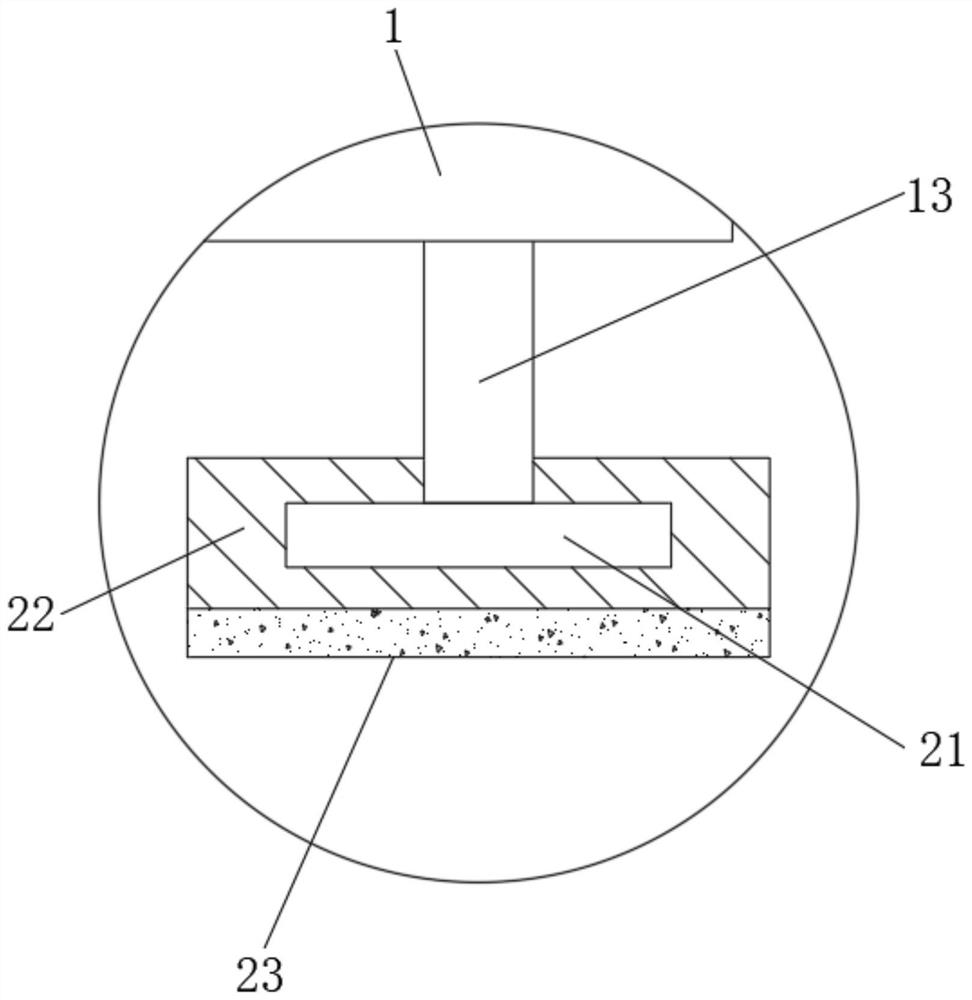

Large-tonnage low-retraction pres-stress anchor and tightening device thereof

InactiveCN102776830AEnsure structural safetyAvoid local weakeningBridge structural detailsBridge erection/assemblyStress concentrationReinforced concrete

The invention discloses a large-tonnage low-retraction pre-stress anchor. The large-tonnage low-retraction pre-stress anchor comprises a bearing plate, an anchor block and a bearing nut, wherein the anchor block is matched with the bearing nut in a threaded manner; the bearing nut is firmly adhered on the bearing plate; a protective cover is arranged on the bearing plate; the anchor block and the bearing nut are covered inside the protective cover; and the bearing plate is a steel plate. According to the large-tonnage low-retraction pre-stress anchor, the bearing plate adopts the steel plate after corrosion prevention and thermal treatment, and can improve rigidity characteristic of the bearing plate, thereby avoiding an occasion that the bearing plate is crushed by the supporting foot in a second large-tonnage tension process; simultaneously, the anchor is externally arranged on a reinforced concrete anchorage region, so that local weakening to the concrete section can be avoided by the anchor structure and the structural safety of the concrete anchorage region is ensured. The invention further discloses a tightening device for the anchor, and the supporting foot of the tightening device is of a sleeve structure, so that the contact area of the supporting foot and the bearing plate can be increased, the stress concentration is reduced, and the occasion that the bearing plate is crushed in the second large-tonnage tension process can be avoided.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

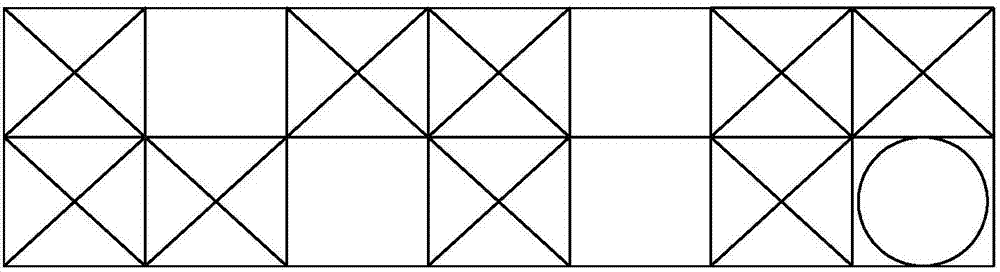

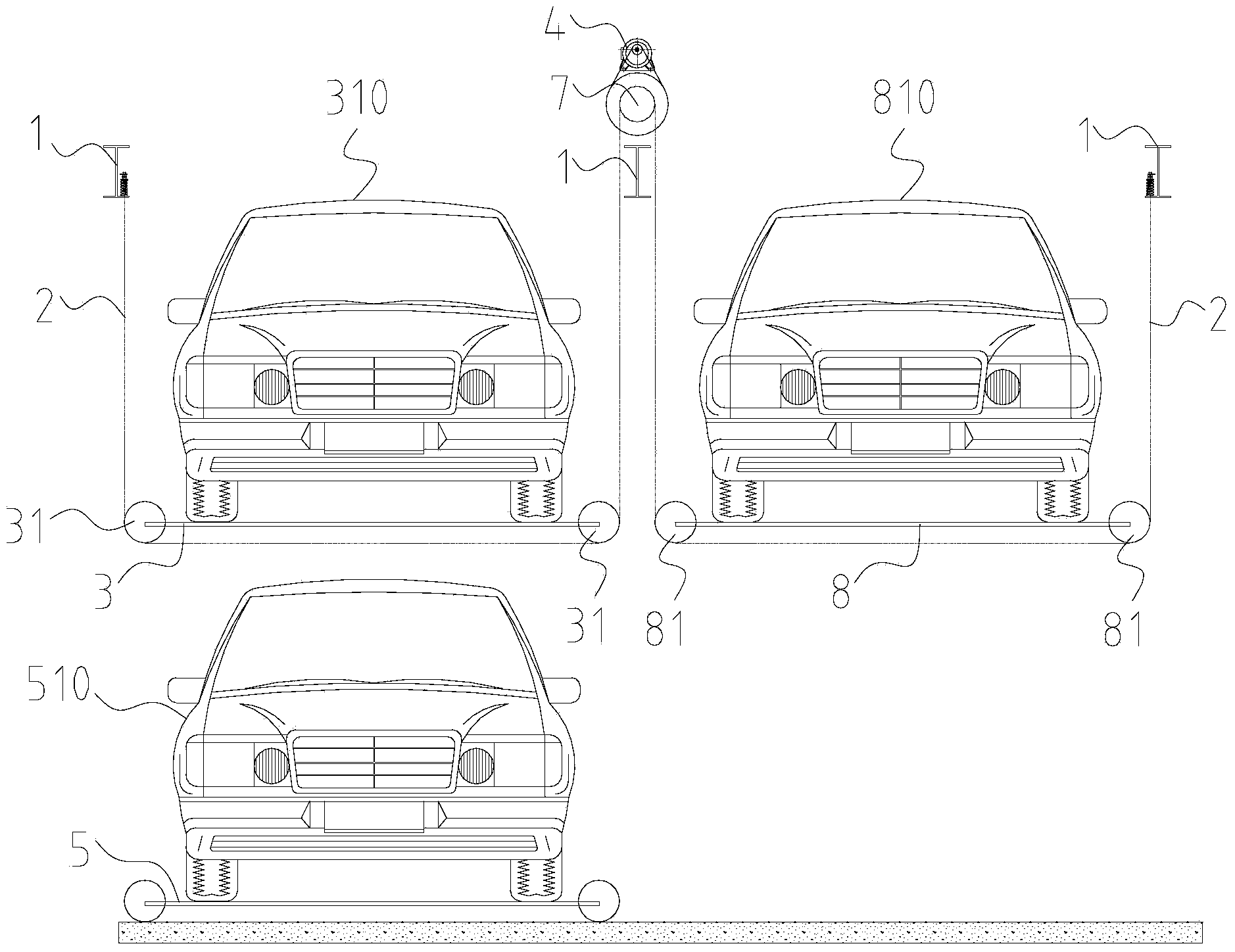

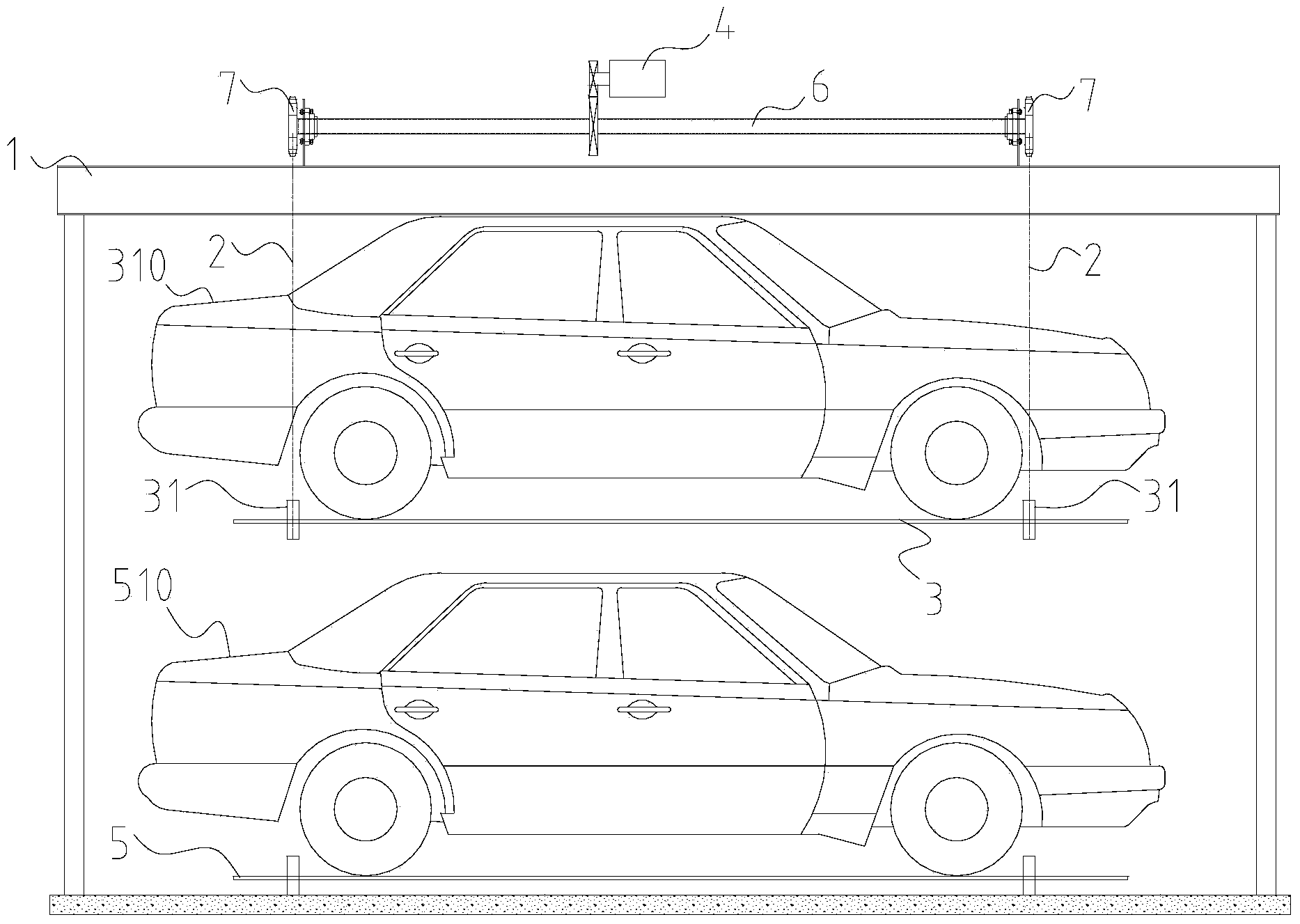

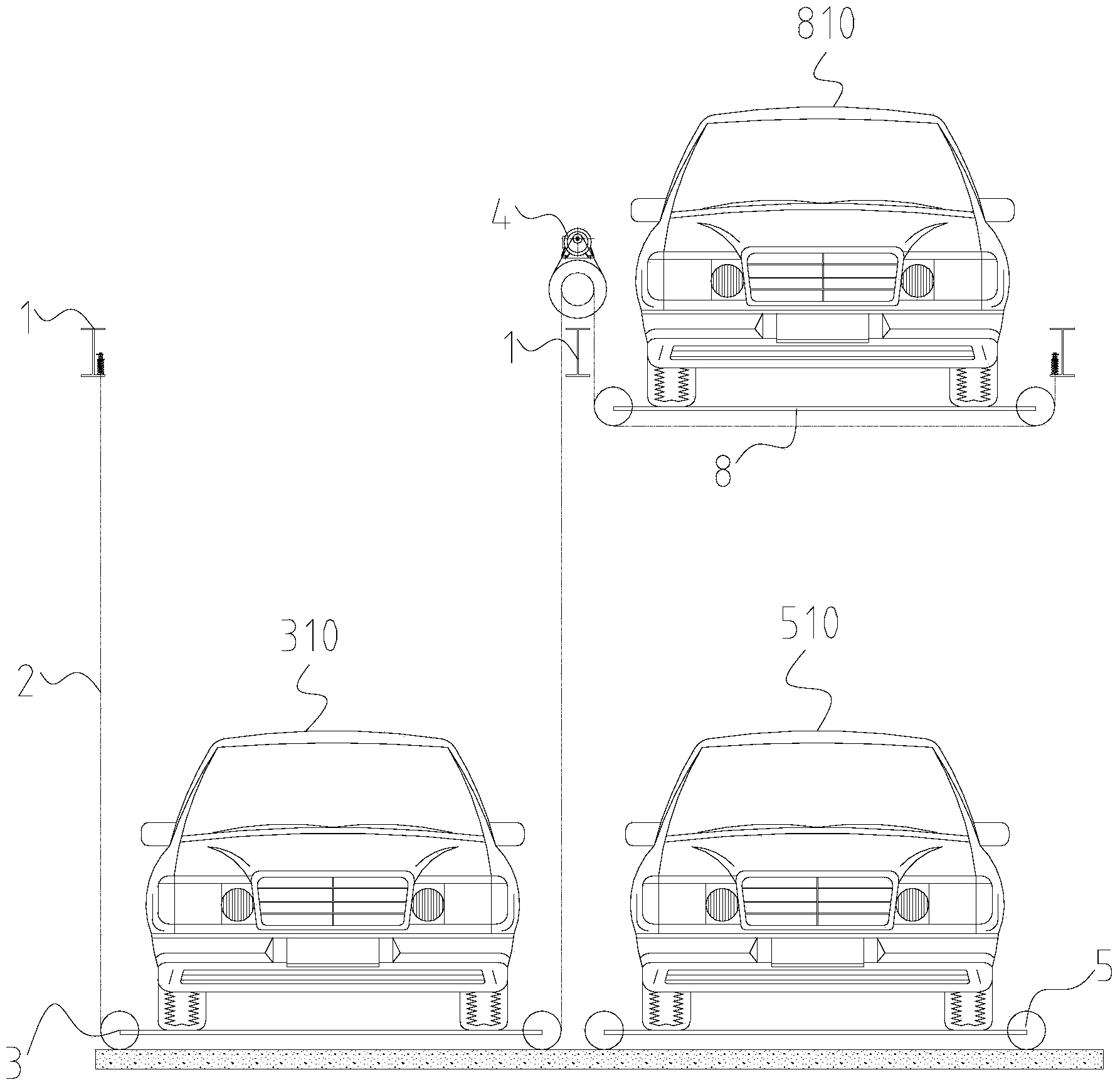

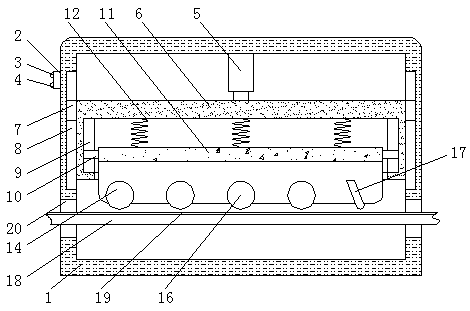

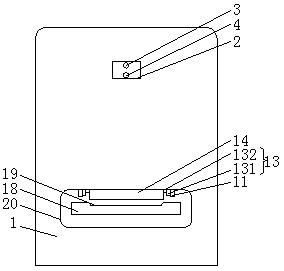

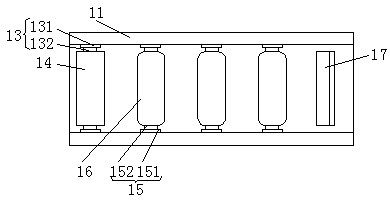

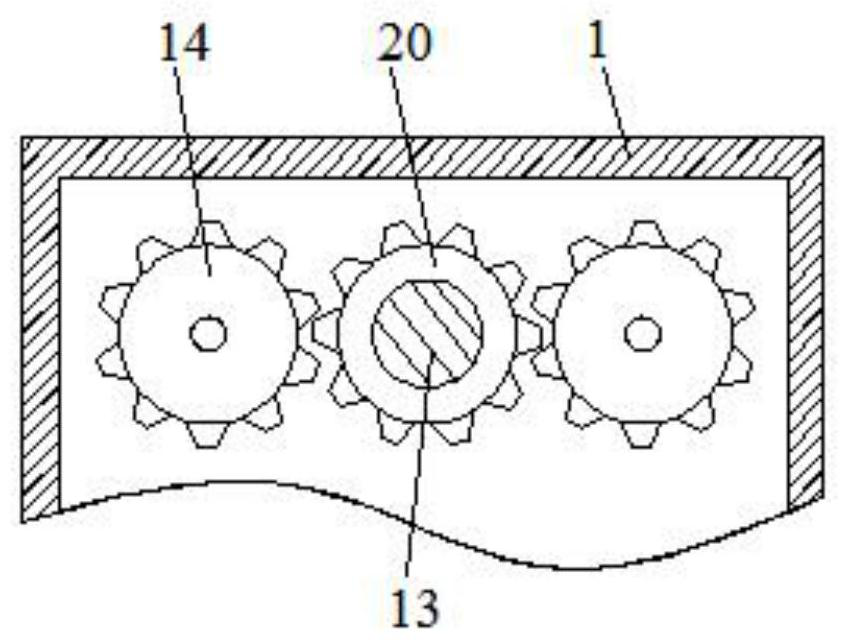

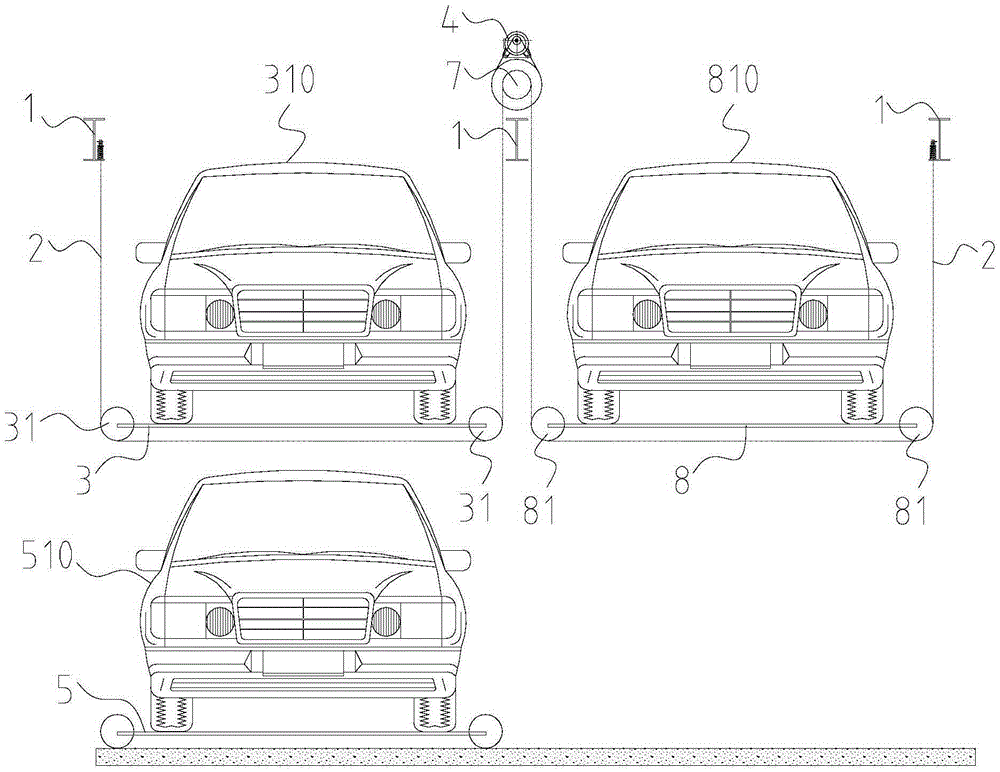

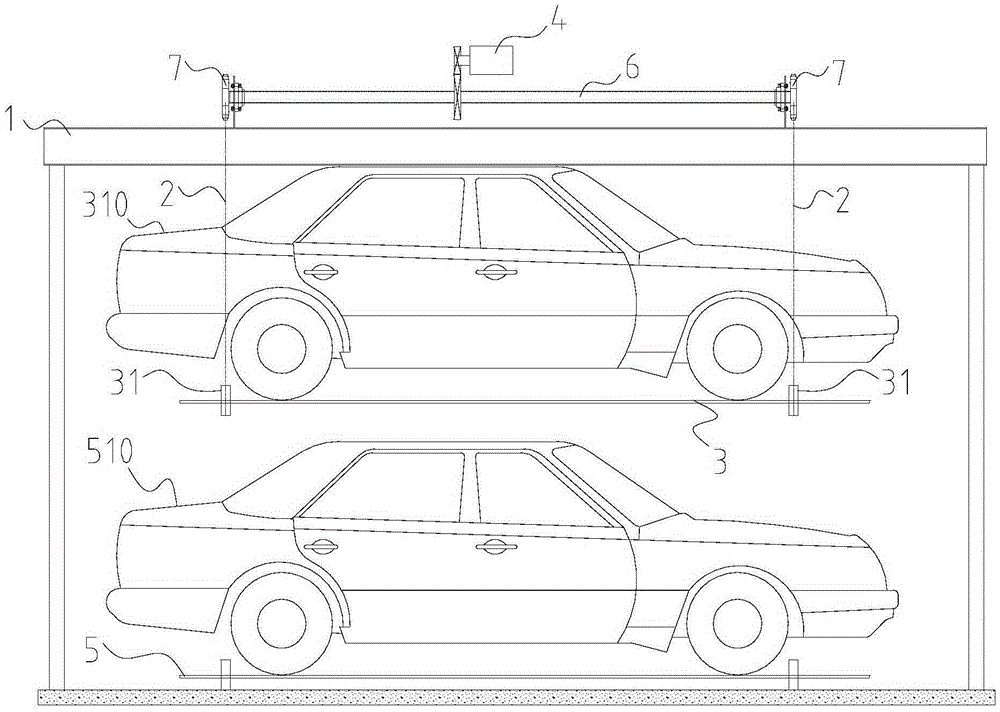

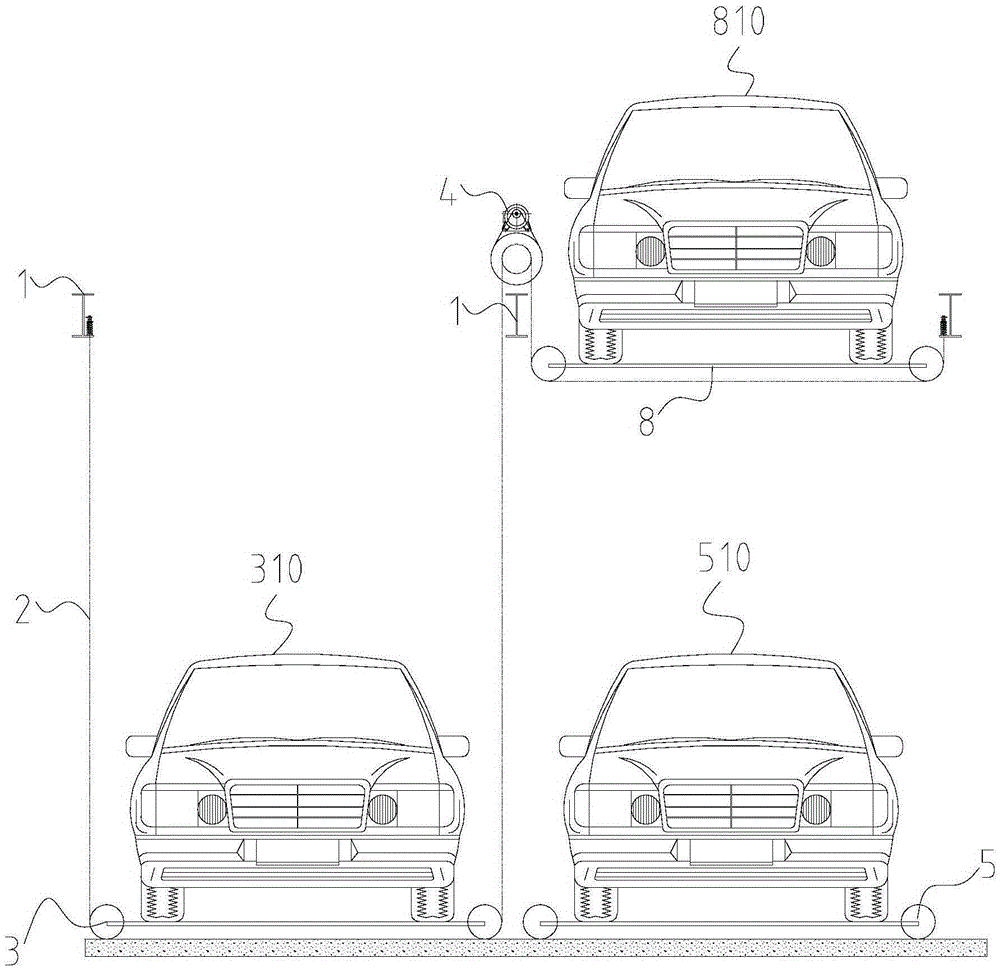

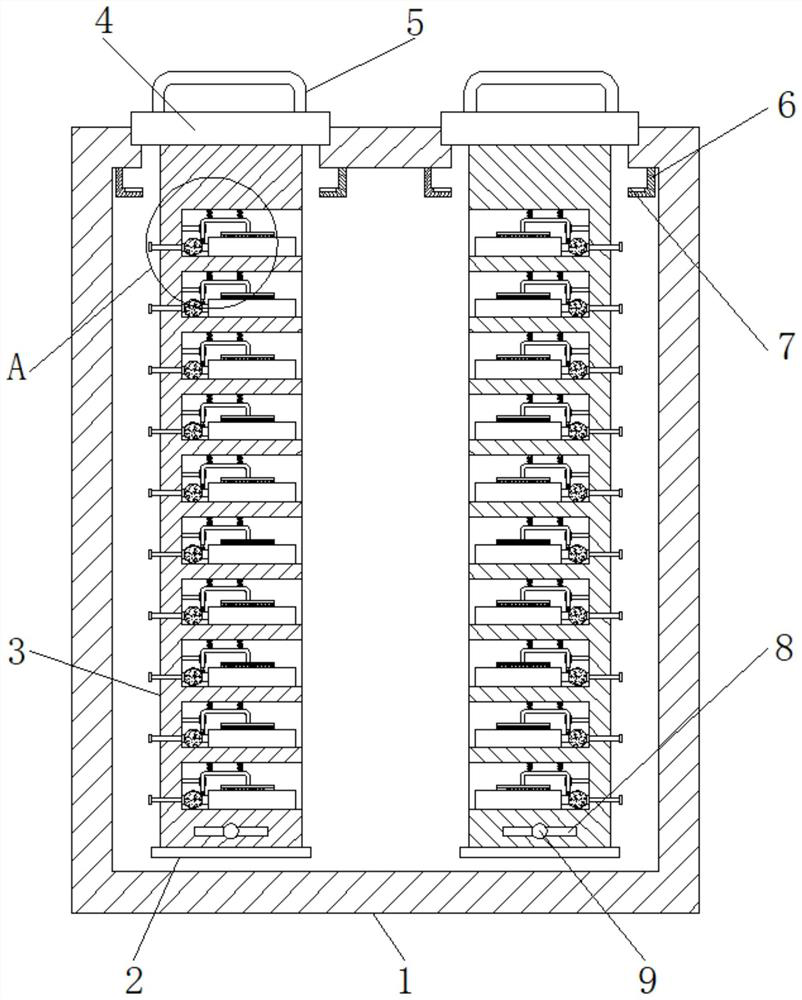

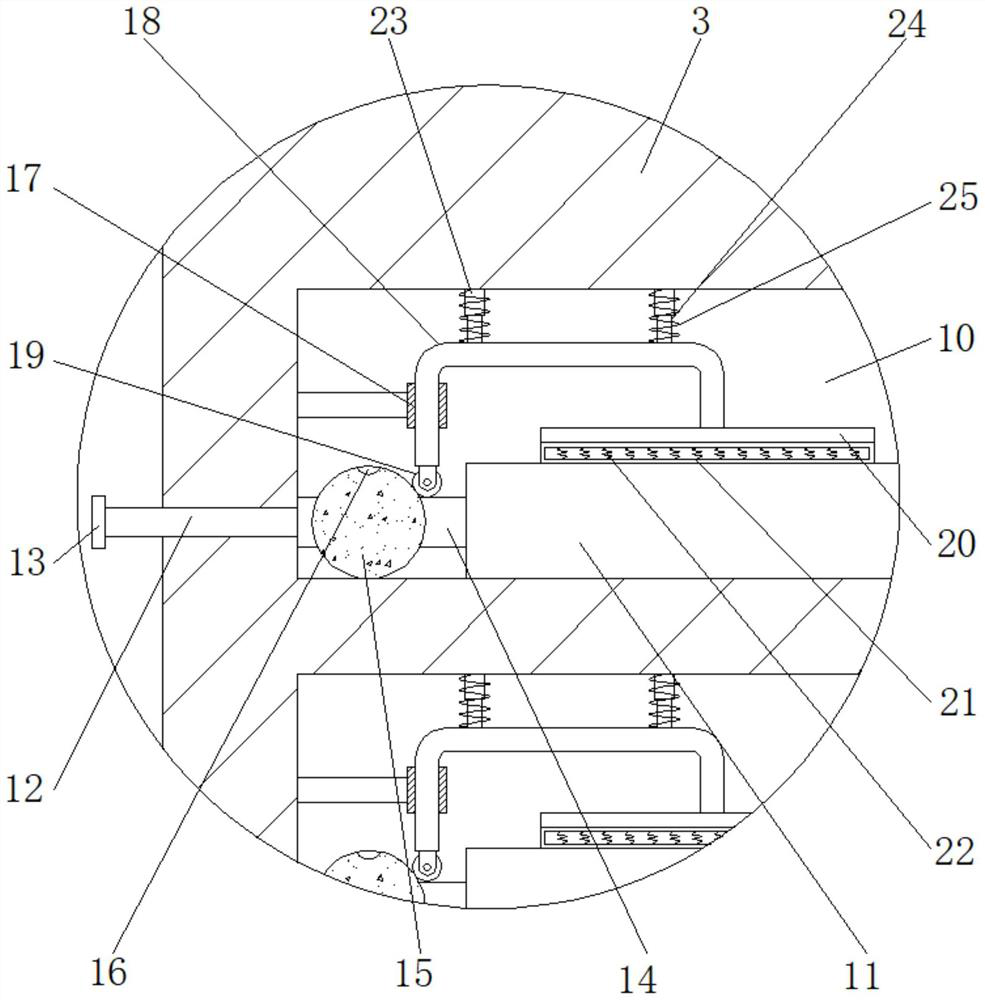

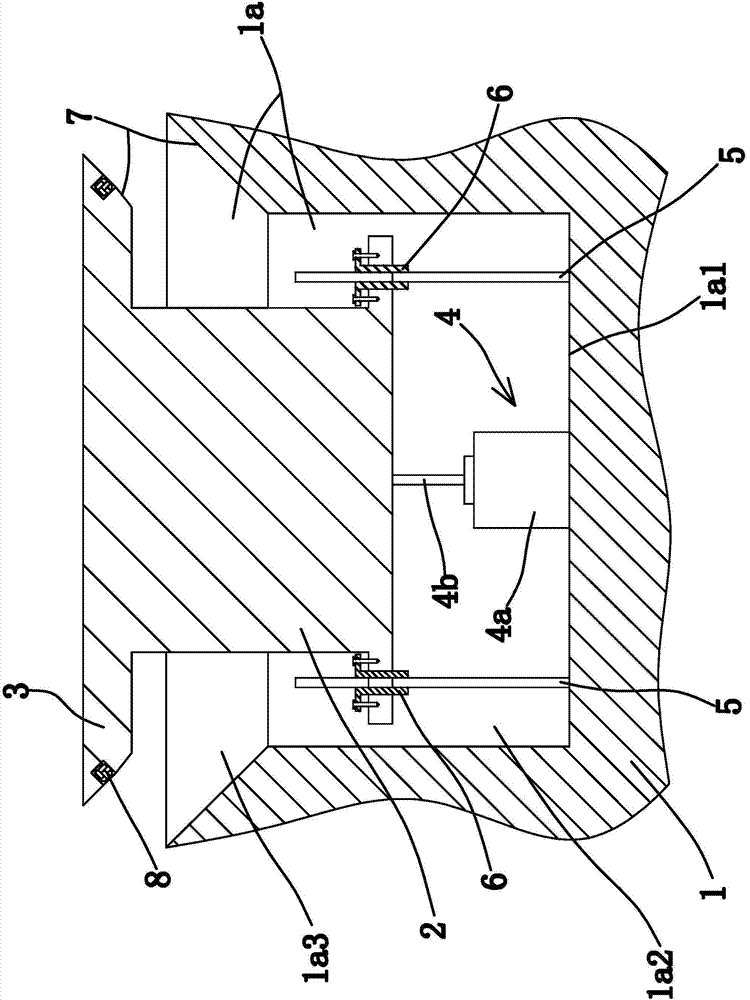

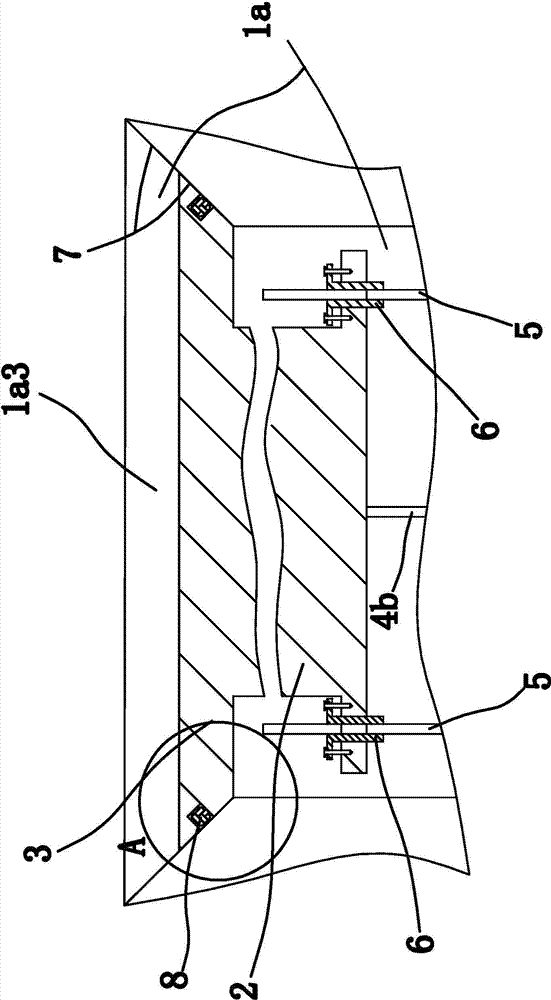

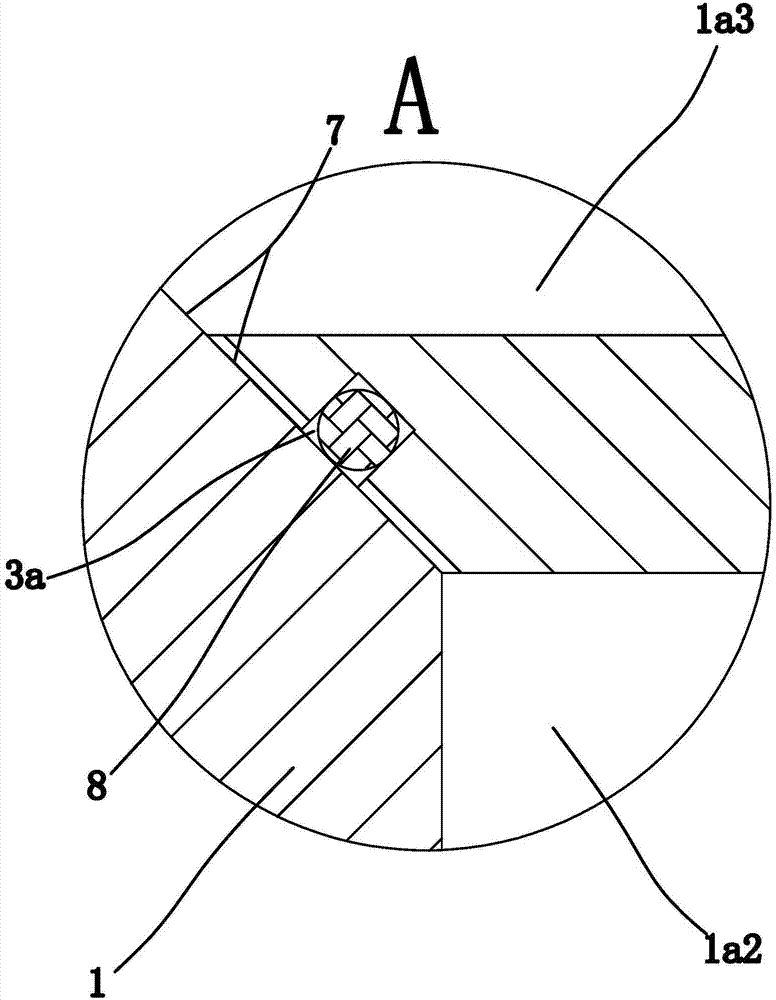

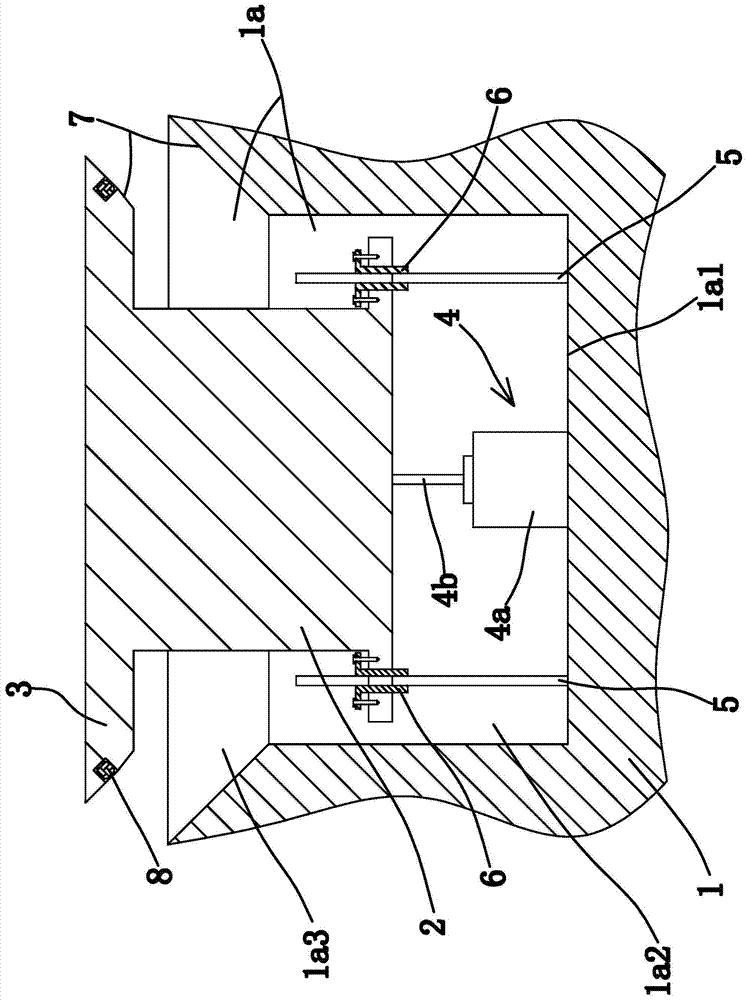

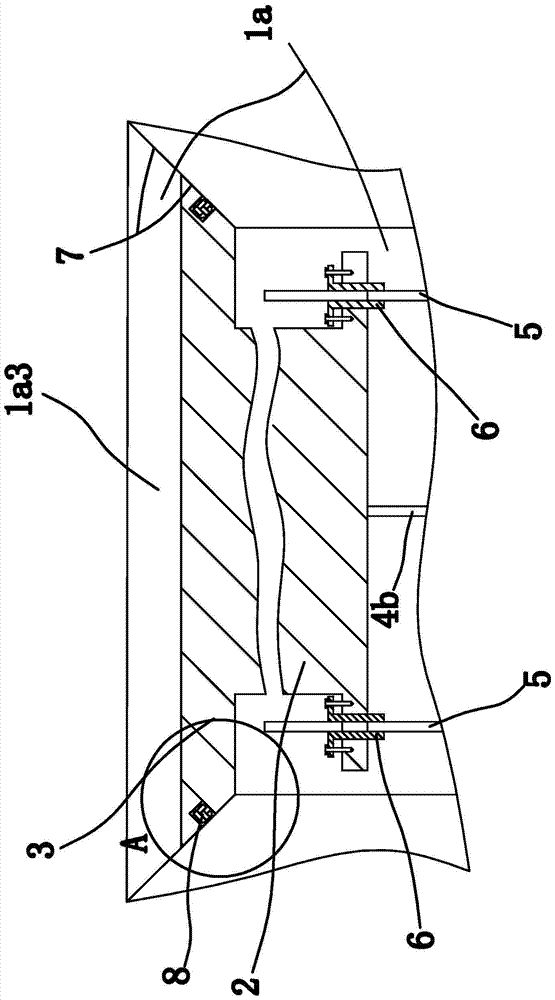

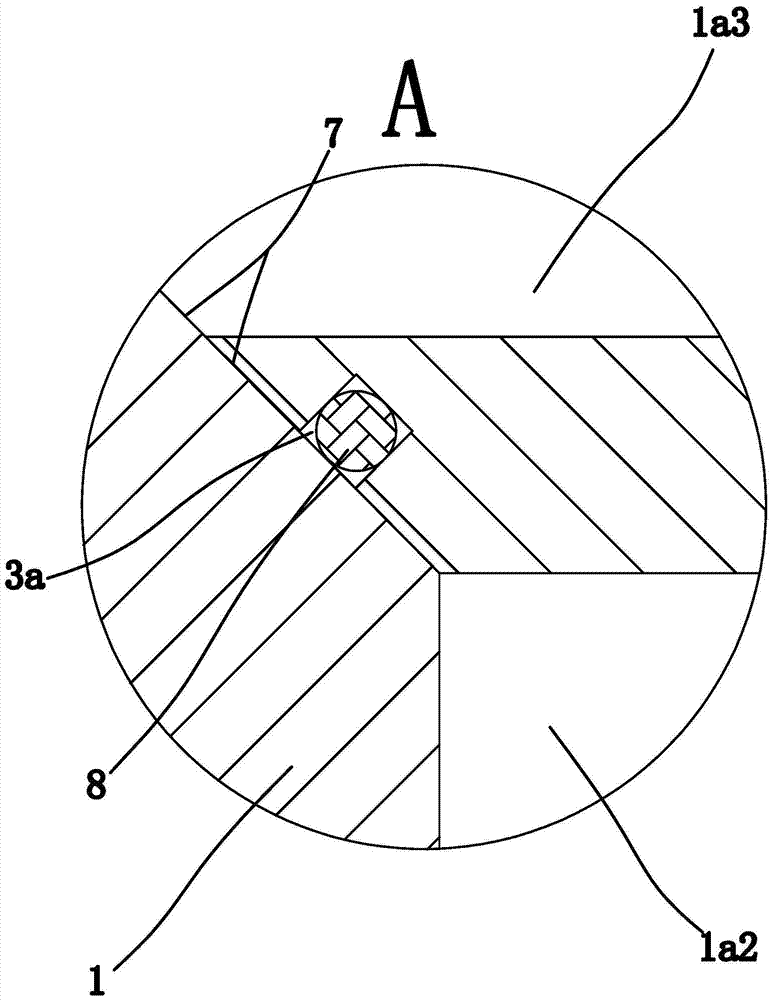

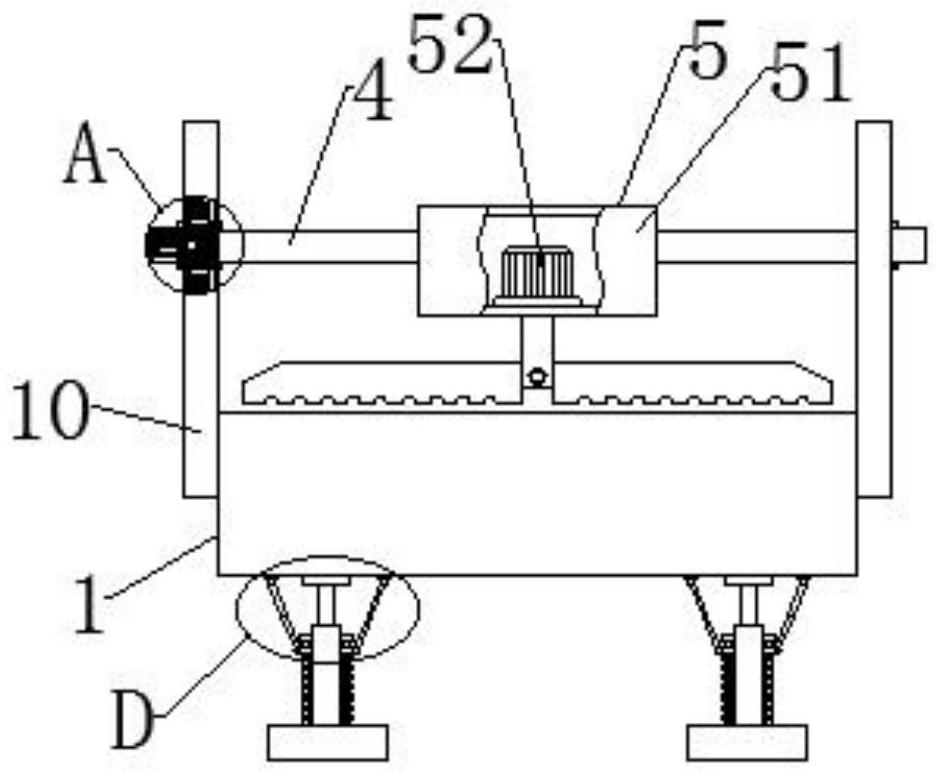

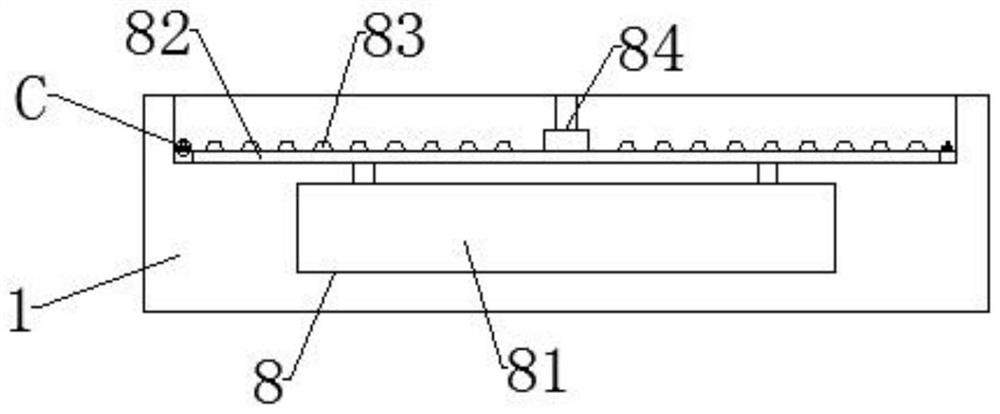

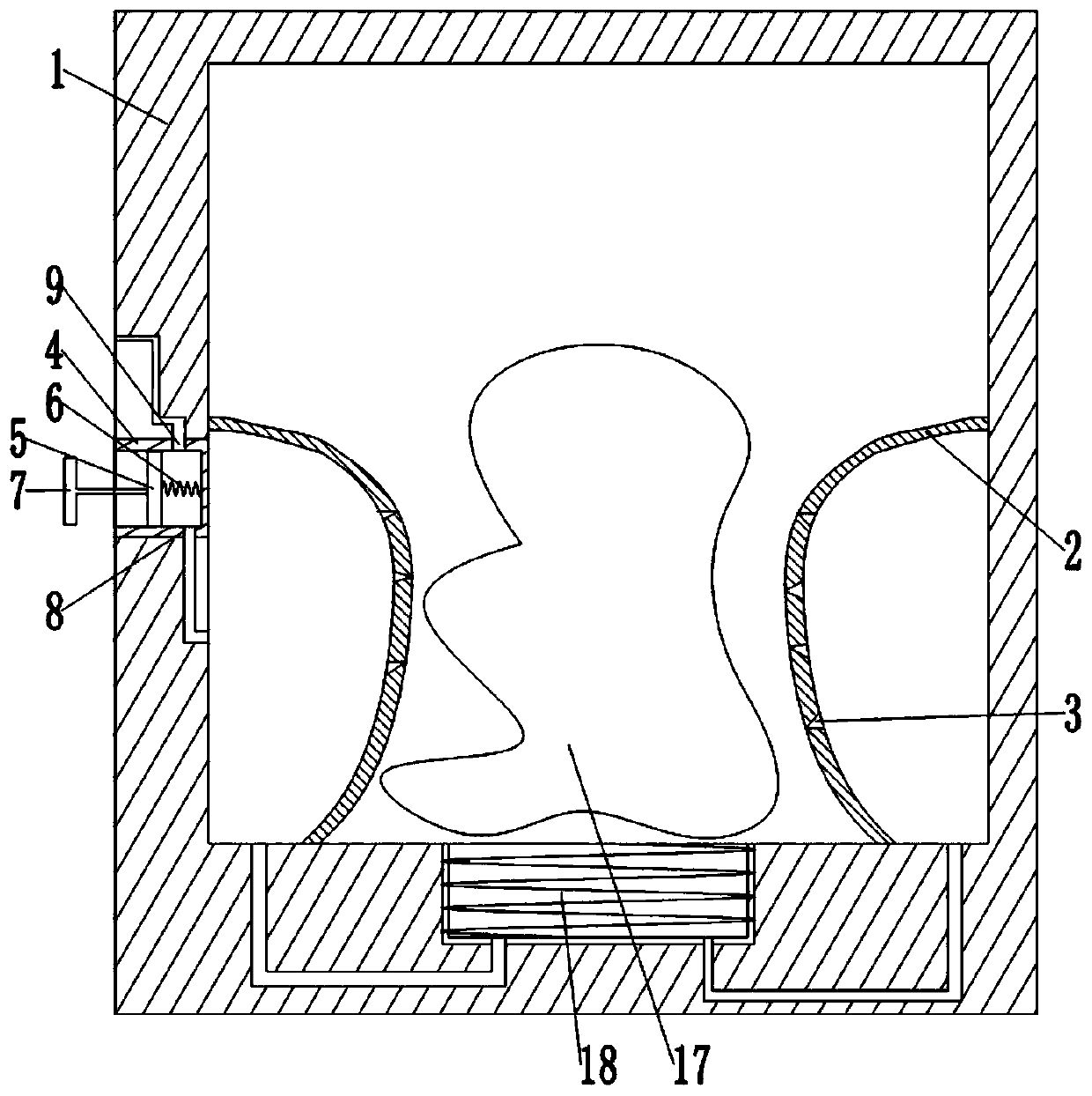

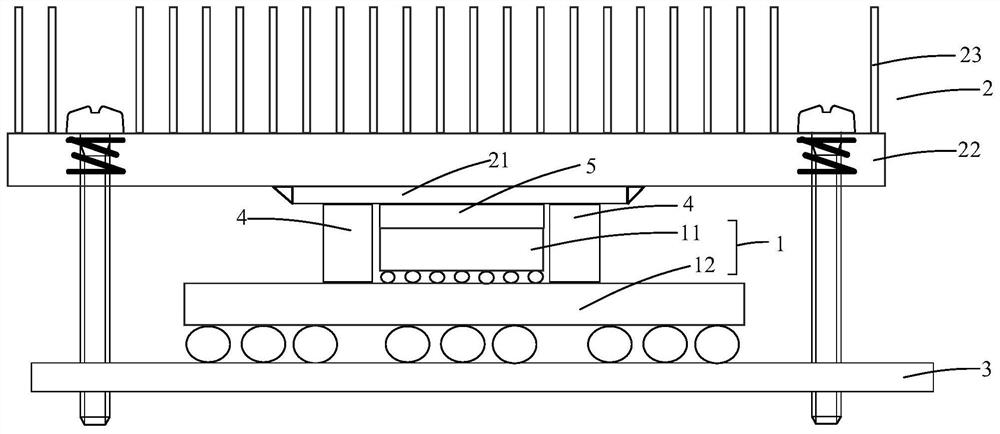

Stereoscopic parking equipment and control method thereof

The invention provides stereoscopic parking equipment and a control method thereof. The stereoscopic parking equipment comprises a garage frame (1), a left upper-layer car carrying plate (3) and a right upper-layer car carrying plate (8) arranged in the garage frame, a bottom-layer car carrying plate (5) arranged in a left-right transverse movement manner, a motor (4) capable of controlling forward and backward rotation, and a transmission sprocket set driven by the motor (4). The transmission sprocket set comprises driving sprockets (7), left driven sprockets (31) respectively mounted on the left and right sides of the right upper-layer car carrying plate (8), and transmission chains (2) connecting the driving sprockets (7), the left driven sprockets (31) and right driven sprockets (81). Compared with the prior art, the stereoscopic parking equipment has the advantages that lifting of the two upper-layer car carrying plates is realized only through one motor, motor number is reduced, manufacturing cost is saved, the motor is low in overall load, and energy consumption is further reduced. Besides, the control method is simple in step, convenient to operate and quite safe.

Owner:SJEC CORP

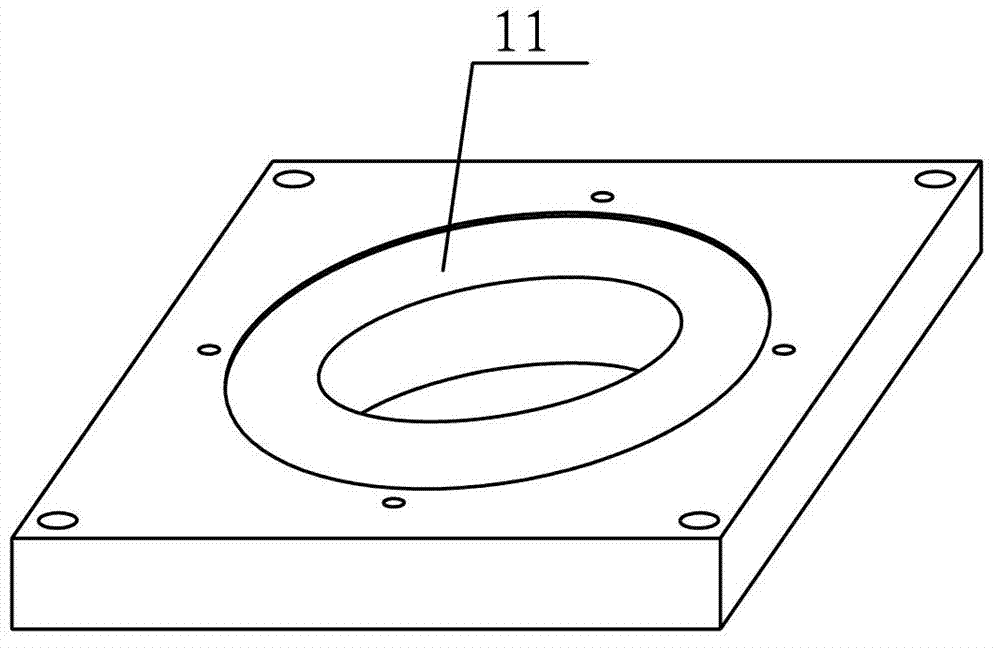

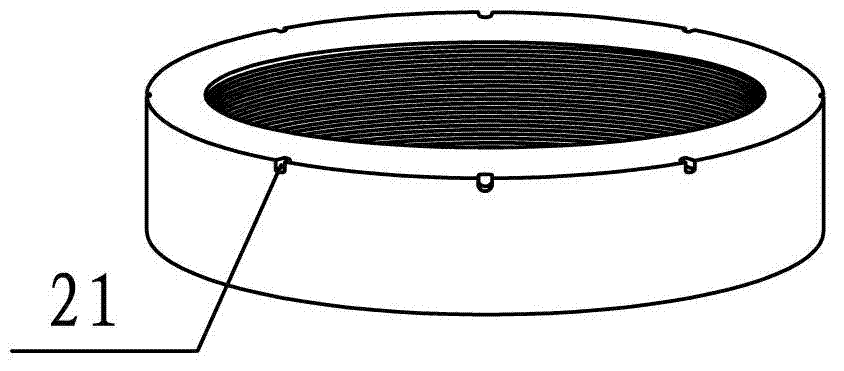

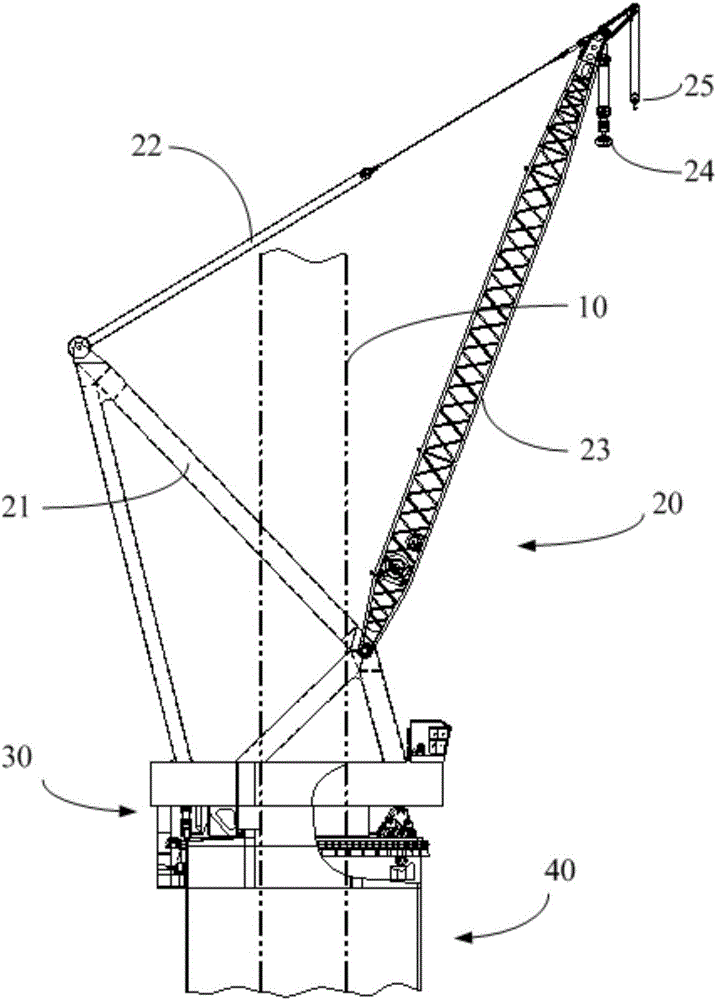

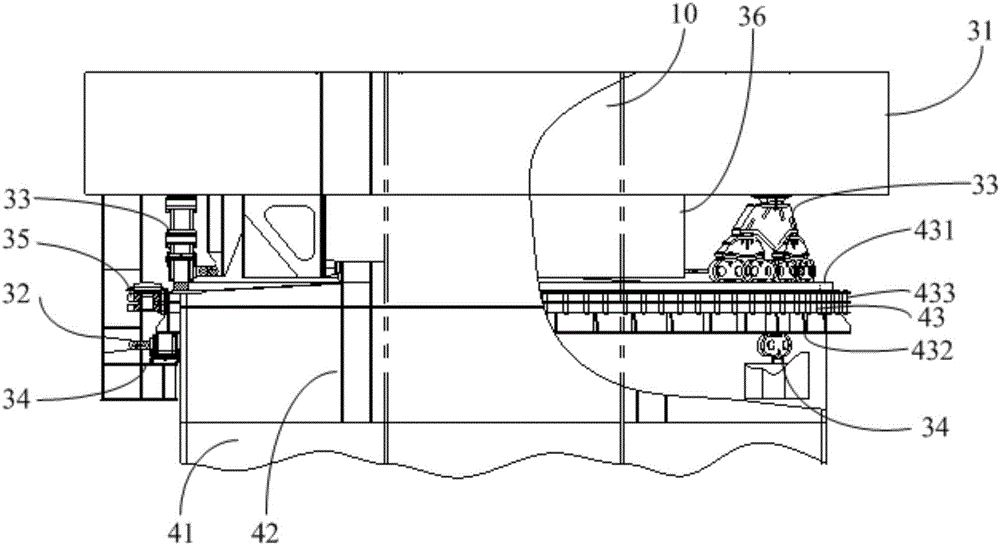

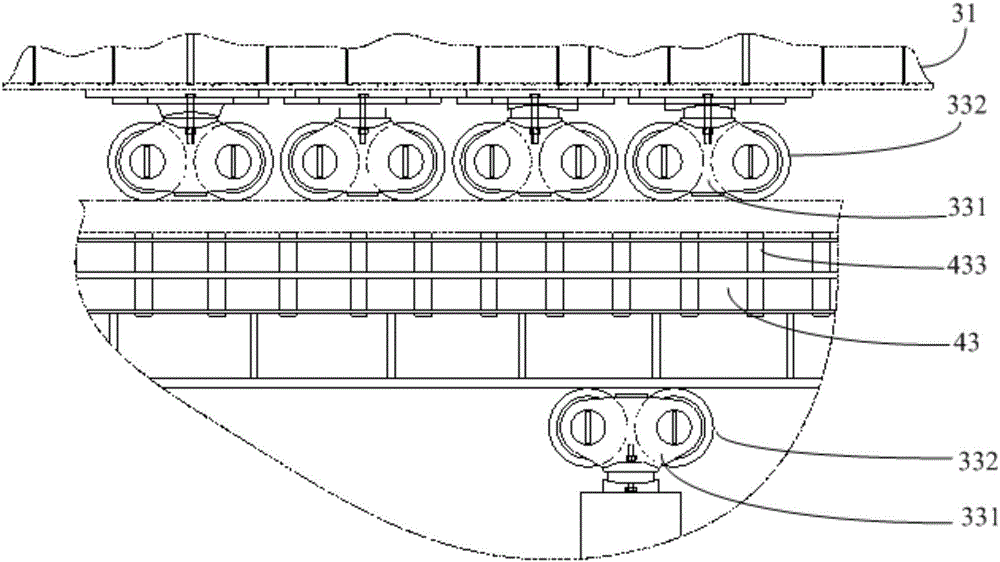

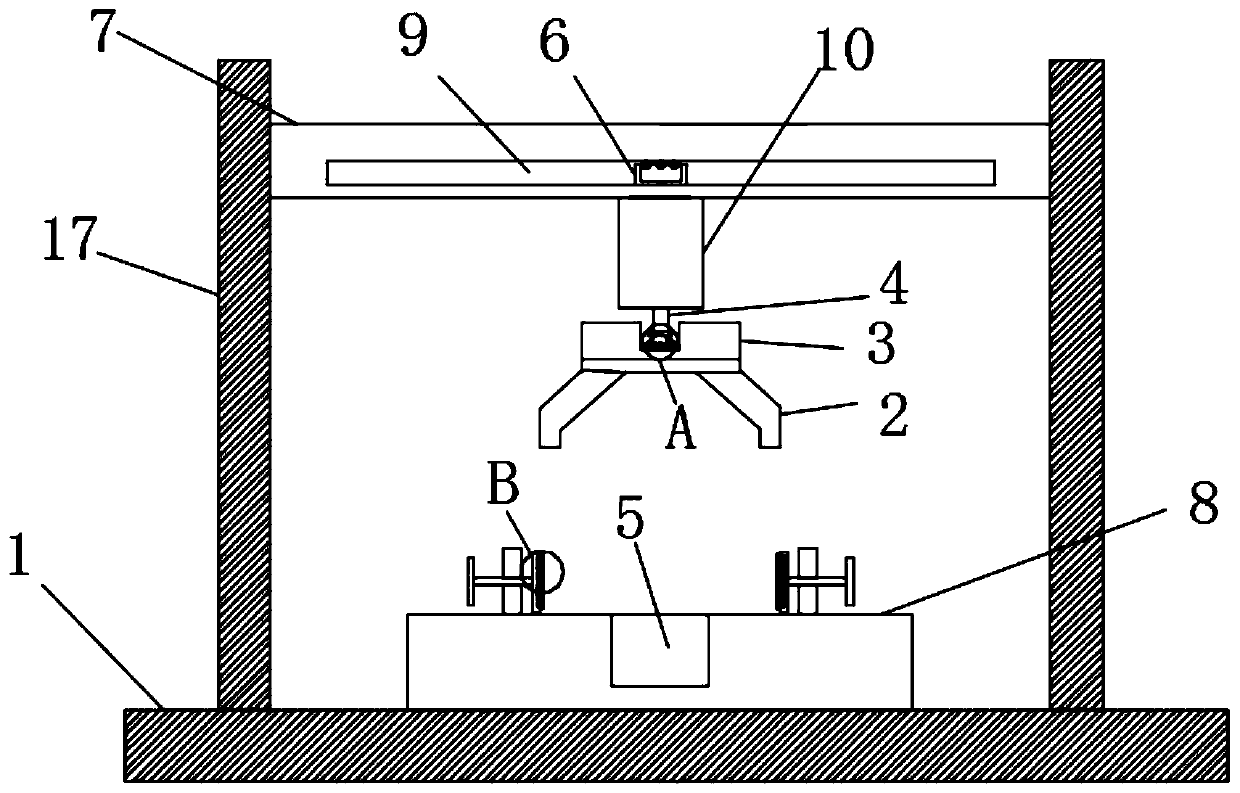

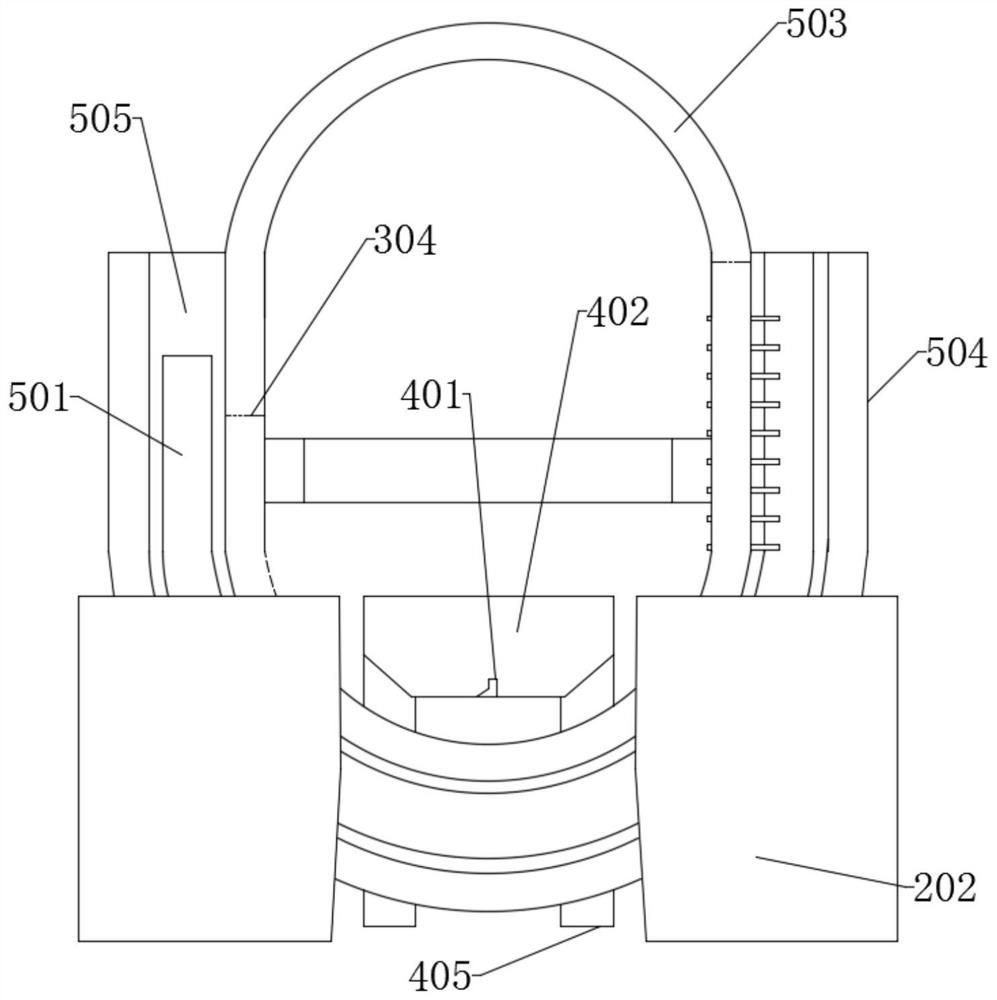

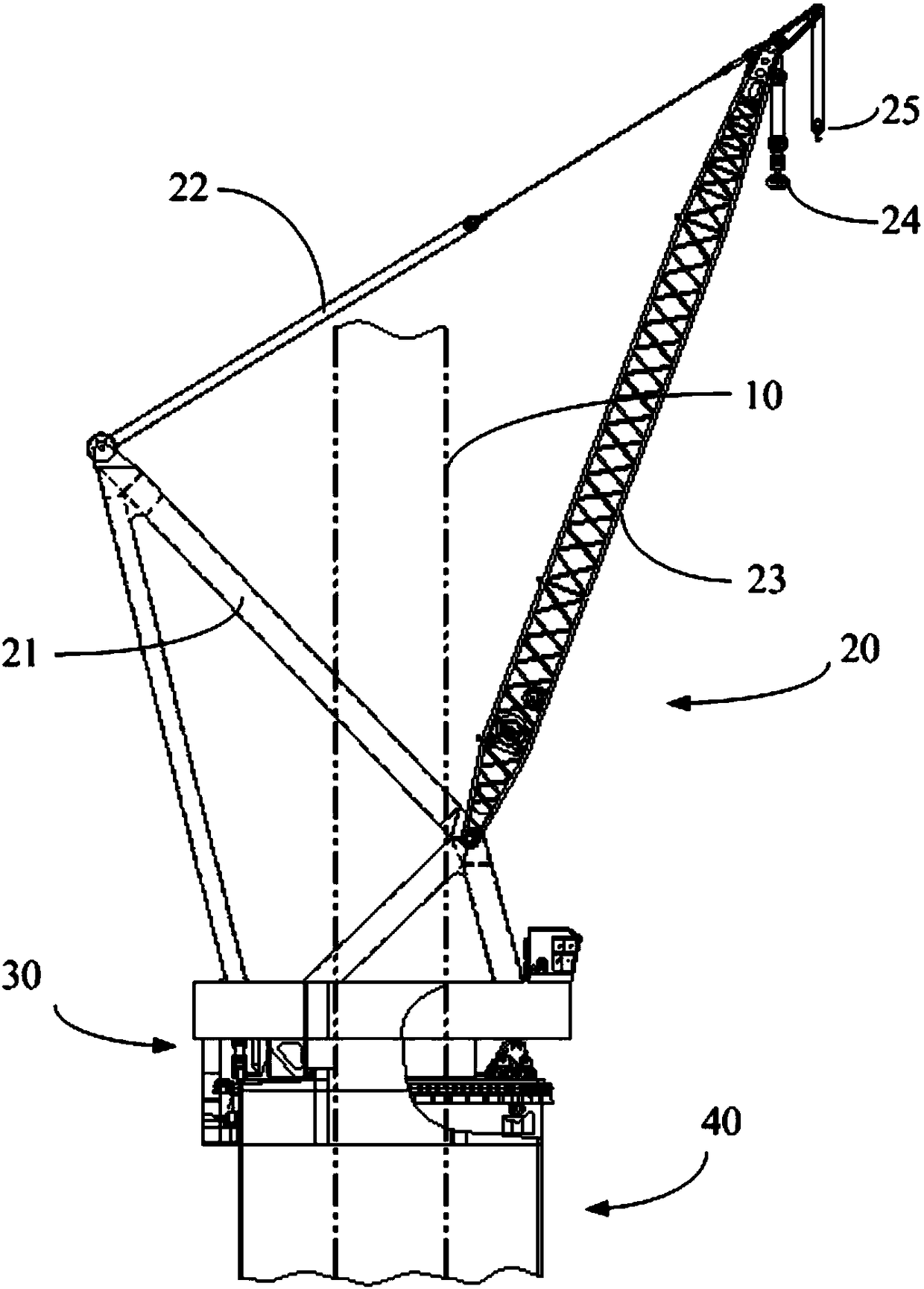

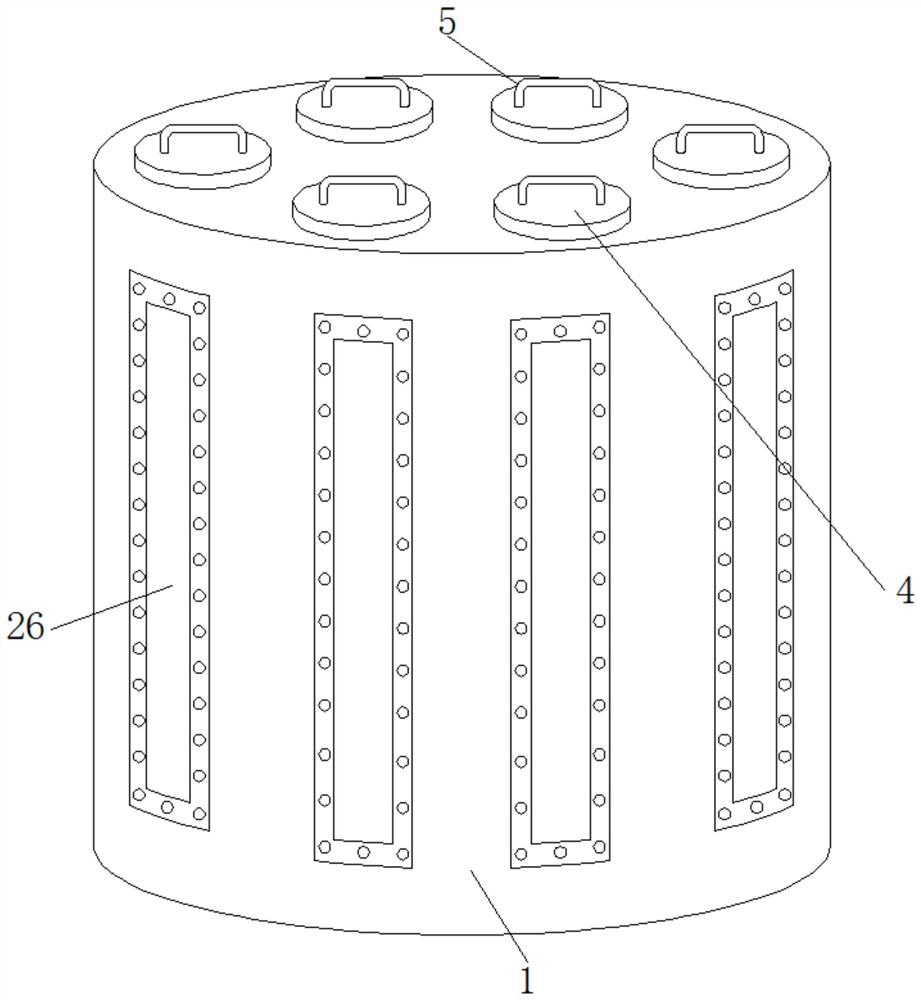

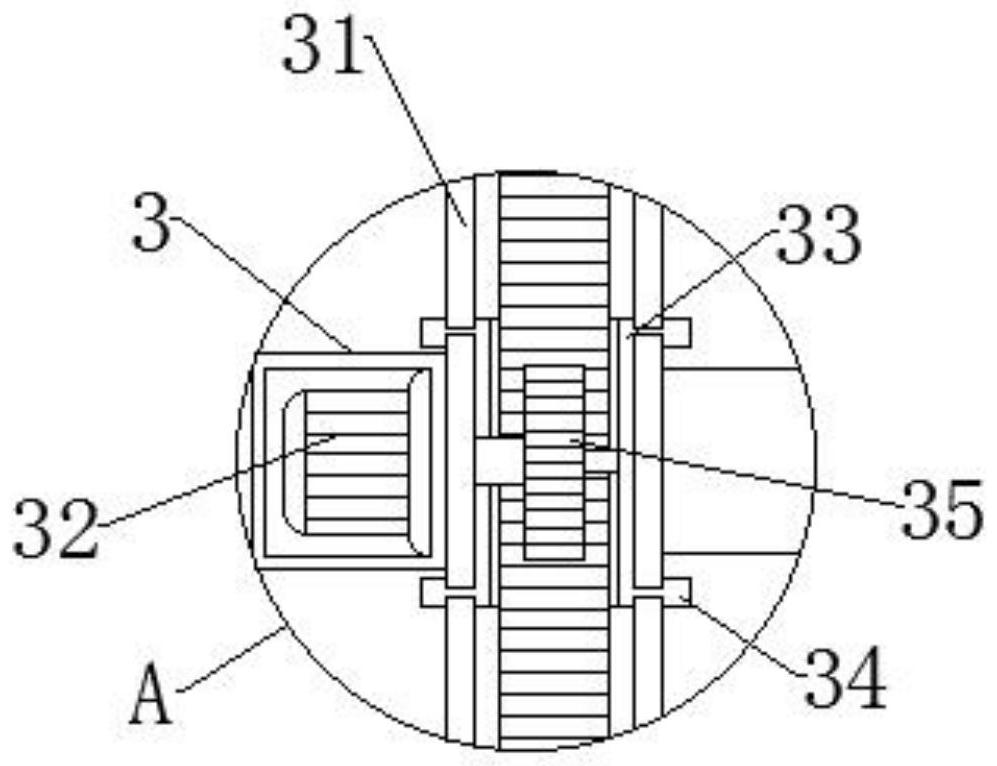

Pile-around revolving crane

The invention discloses a pile-around revolving crane and belongs to the field of cranes. The pile-around revolving crane comprises a lifting mechanism, a revolving platform and a base. The revolving platform is arranged at the upper end of the base, the lifting mechanism is arranged on the revolving platform, the base comprises a fixed base, a cylindrical supporting column and a revolving supporting ring, one end of the cylindrical supporting column is connected to the fixed base, and the other end of the cylindrical supporting column is connected to the revolving supporting ring. The revolving platform comprises a rotary table, a forward roller assembly and a backward roller assembly. The forward roller assembly is arranged on the rotary table, and the backward roller assembly is arranged on the rotary table through a backward roller supporting base. The forward roller assembly and the backward roller assembly each comprise a roller support and a roller, wherein the roller support is rotationally connected to the rotary table or the backward roller supporting base, and the roller rolls on the upper and lower surfaces of the revolving supporting ring along with rotation of the revolving platform. Due to the fact that the revolving plane of each roller support is parallel to the revolving axis of the revolving platform, when the surface of the revolving supporting ring is not flat, the roller supports will revolve to enable the rollers to press the revolving supporting ring.

Owner:WUHAN MARINE MACHINERY PLANT

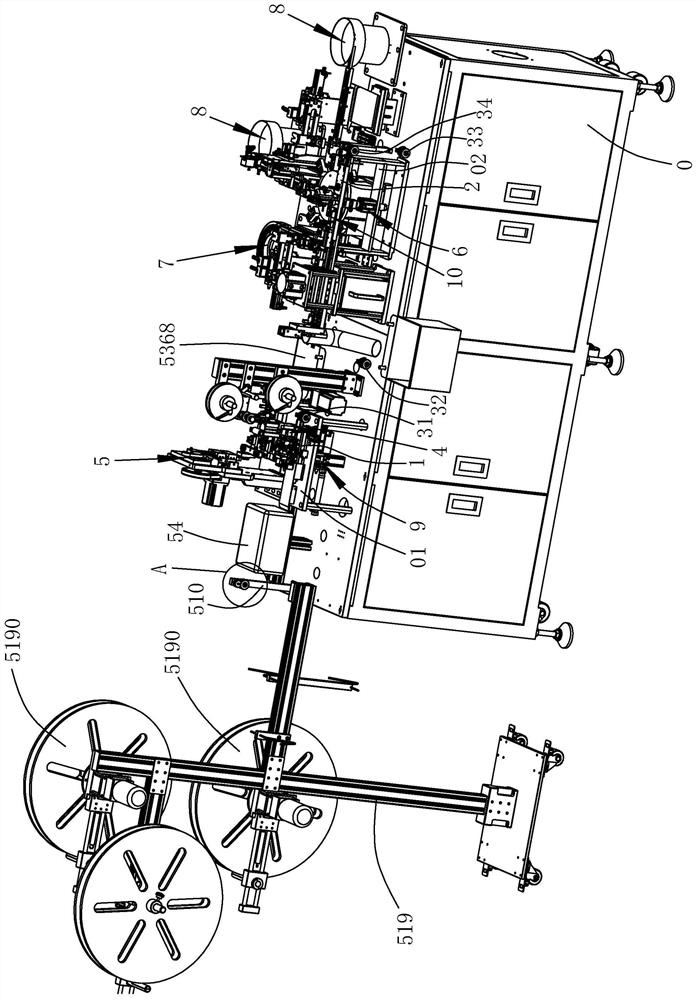

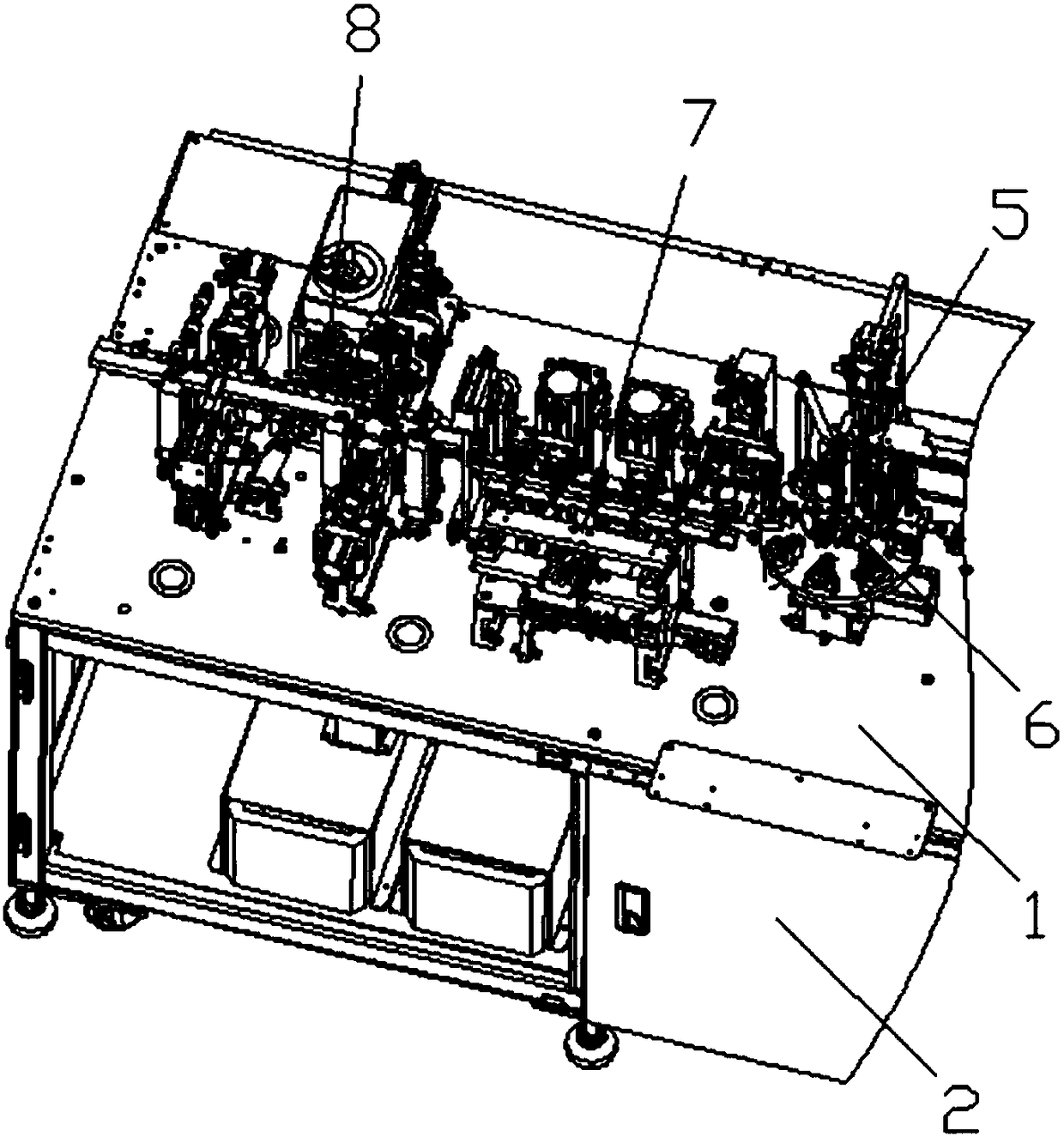

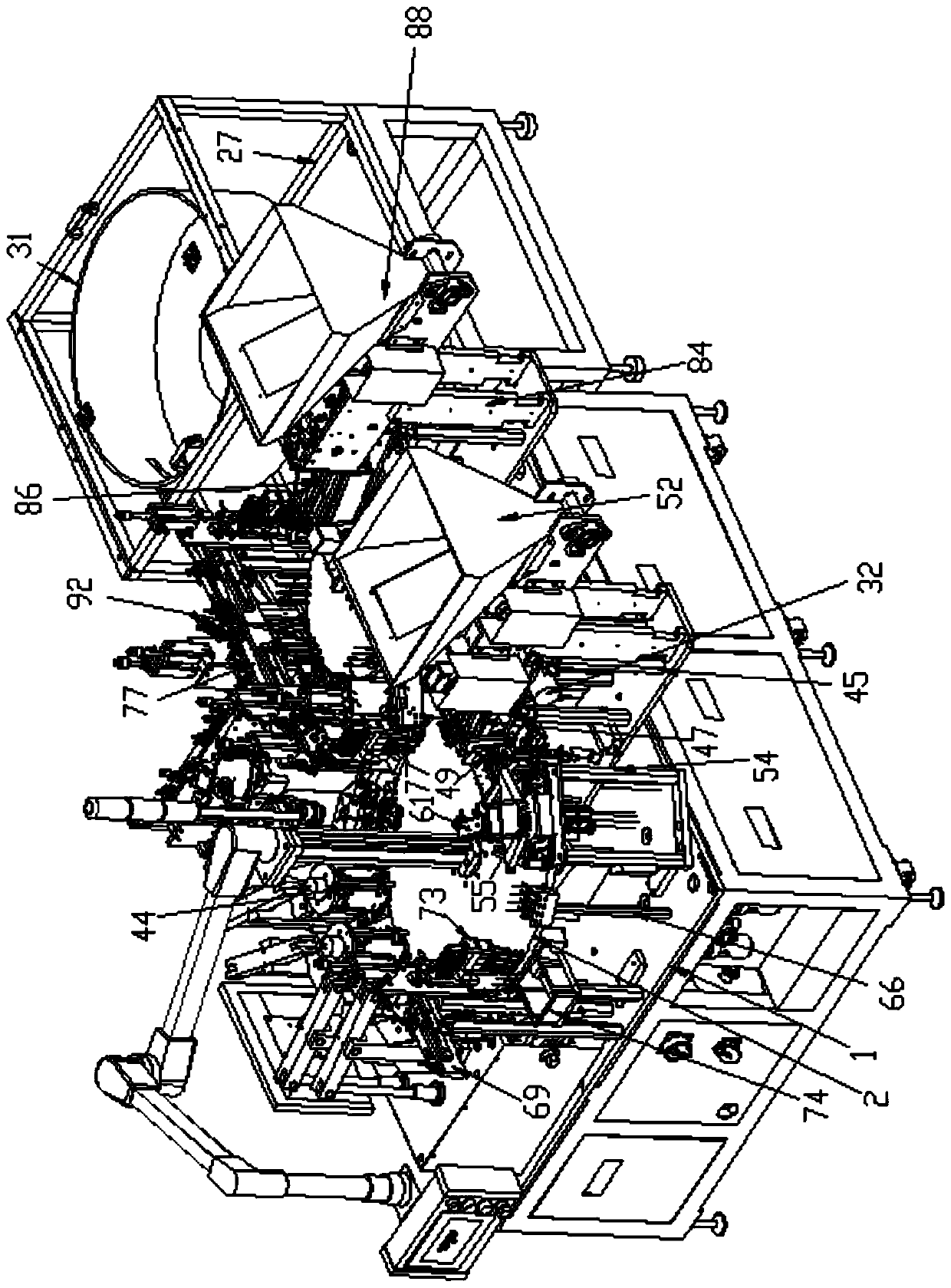

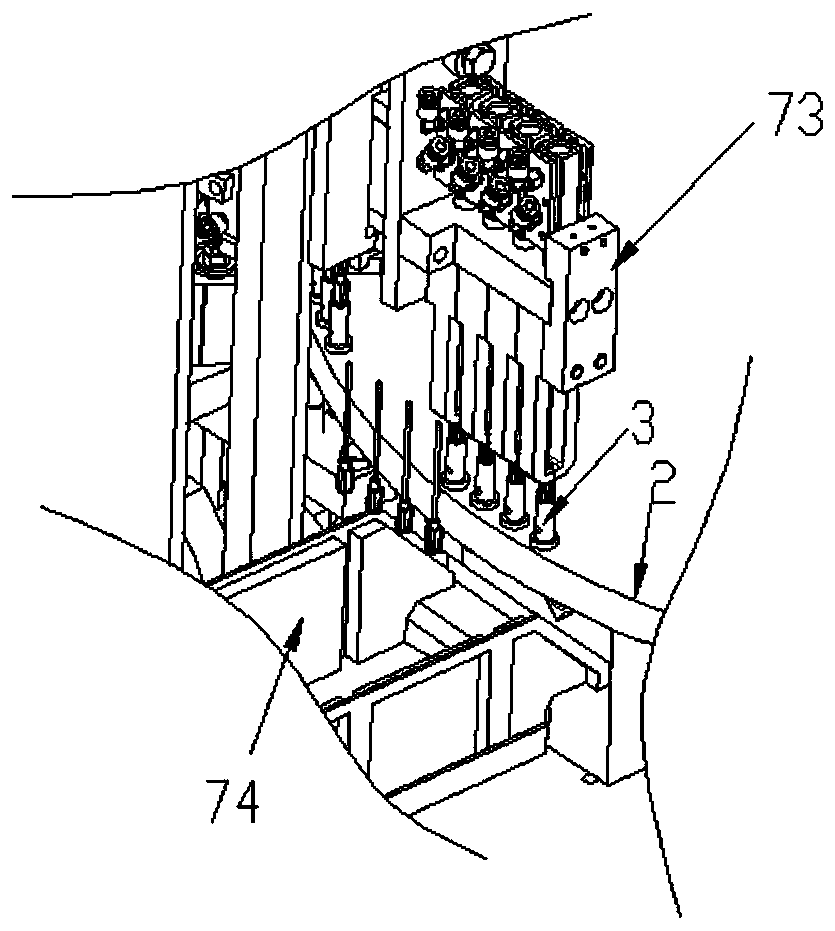

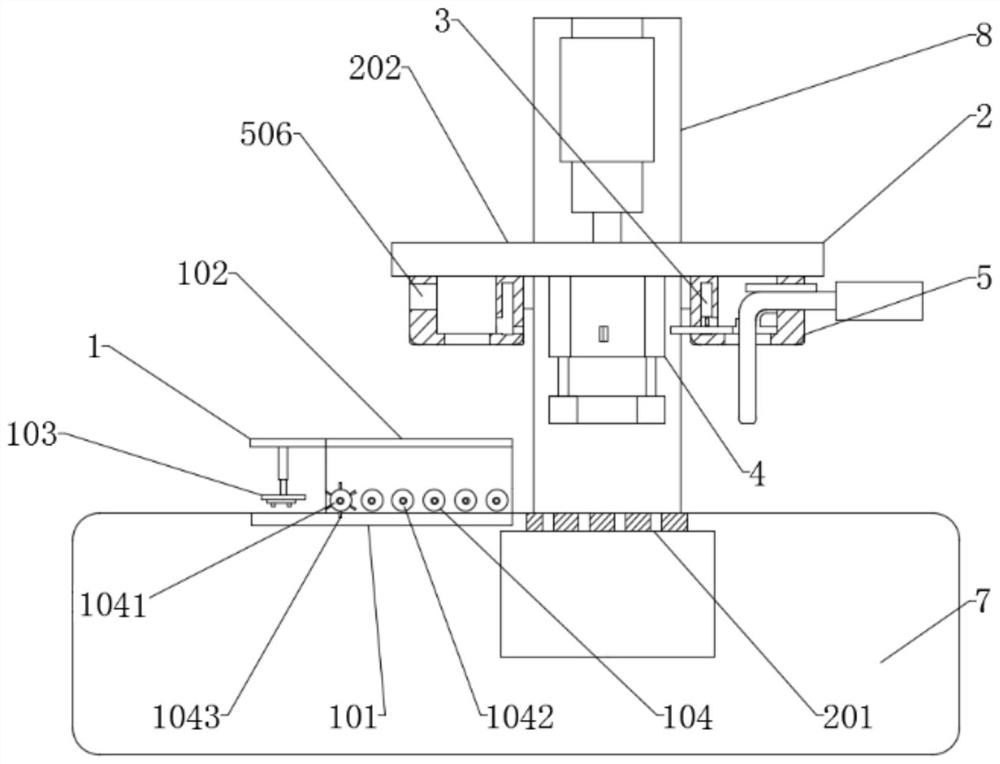

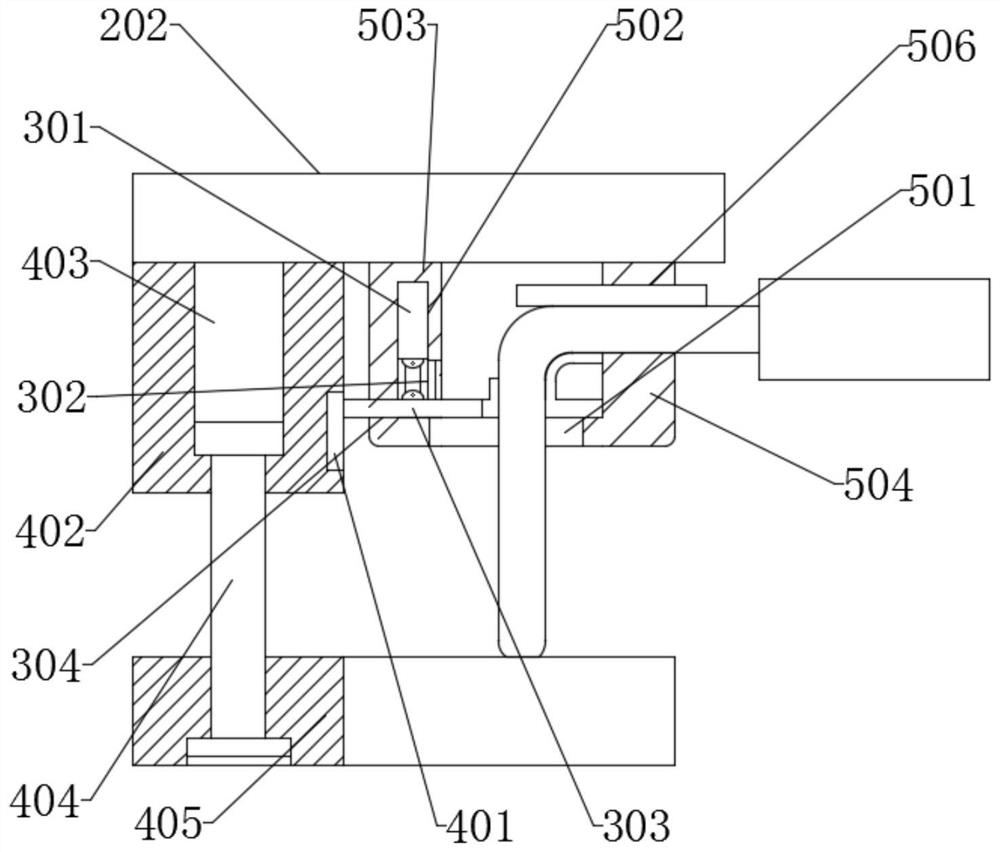

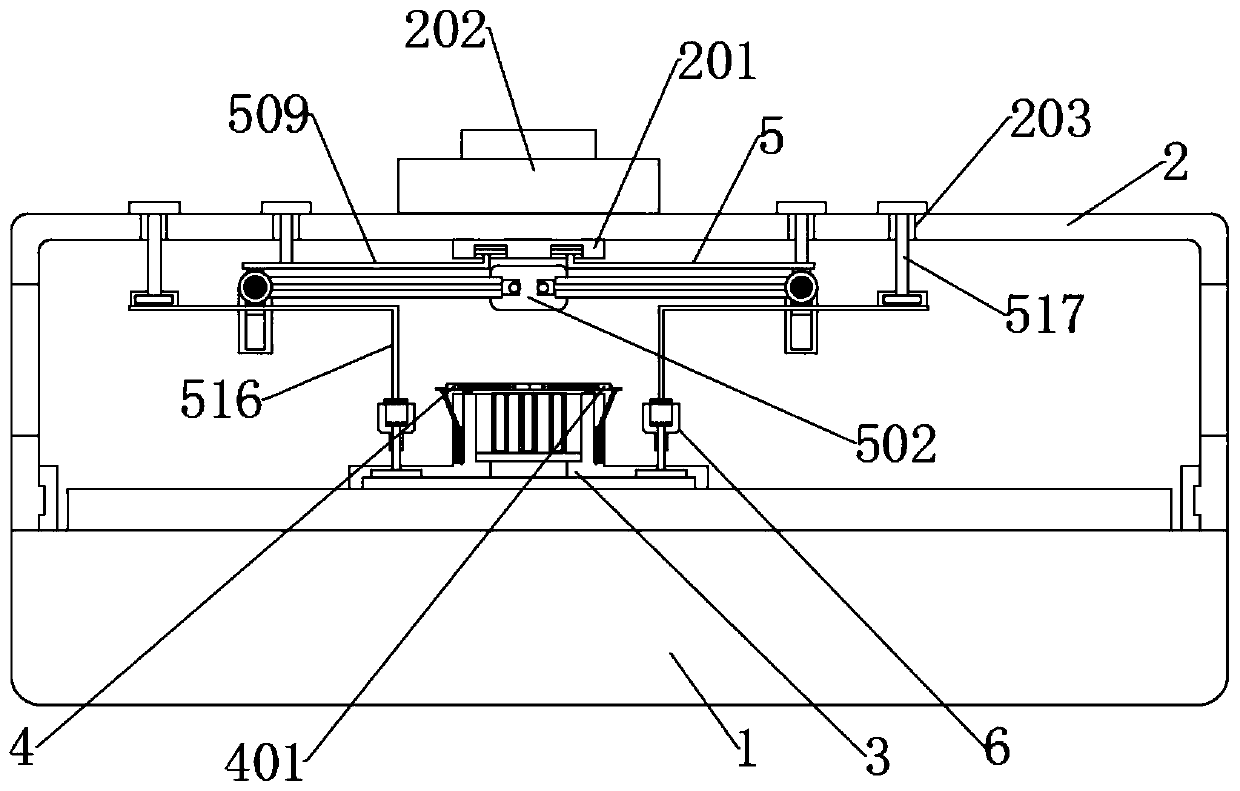

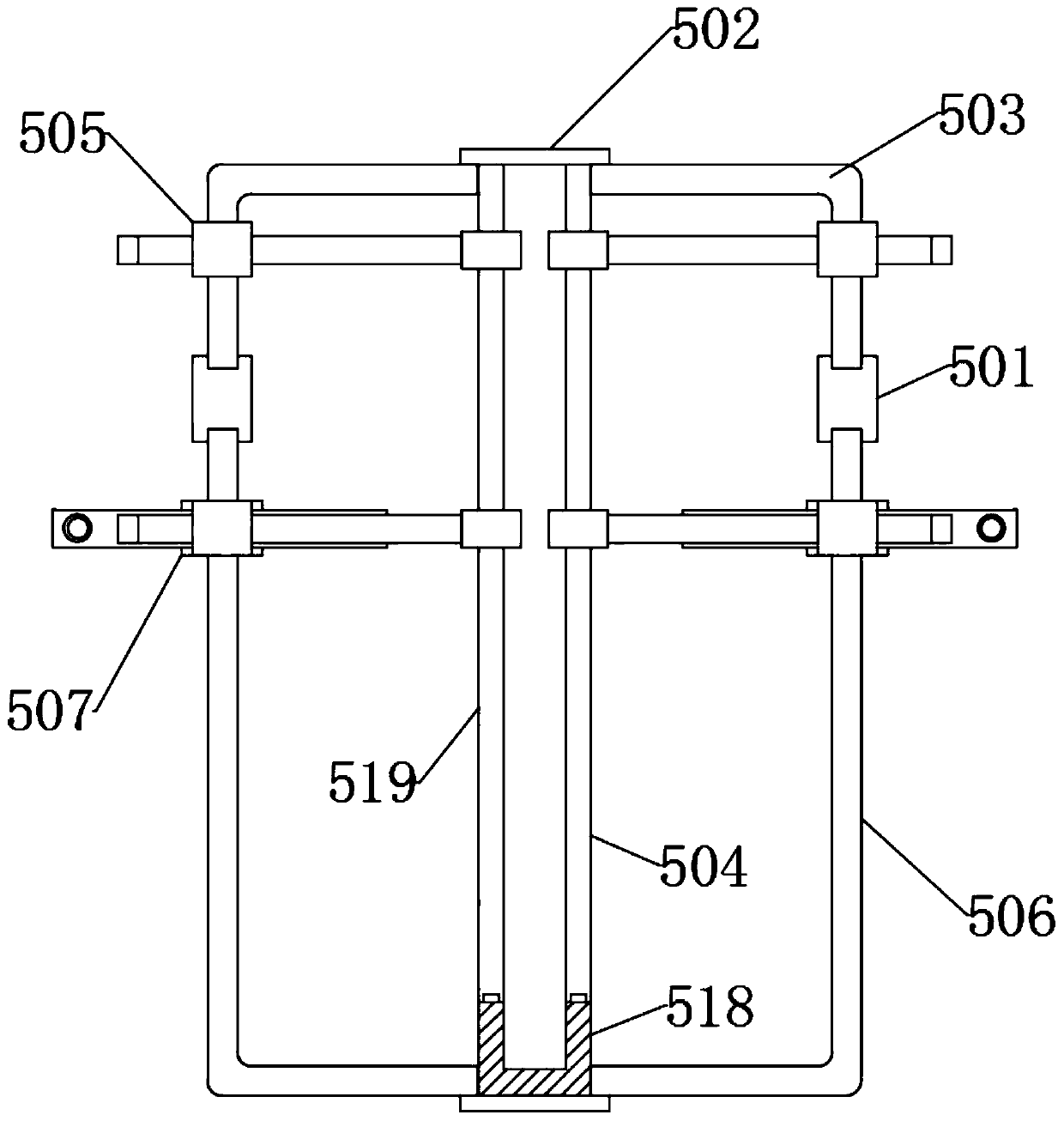

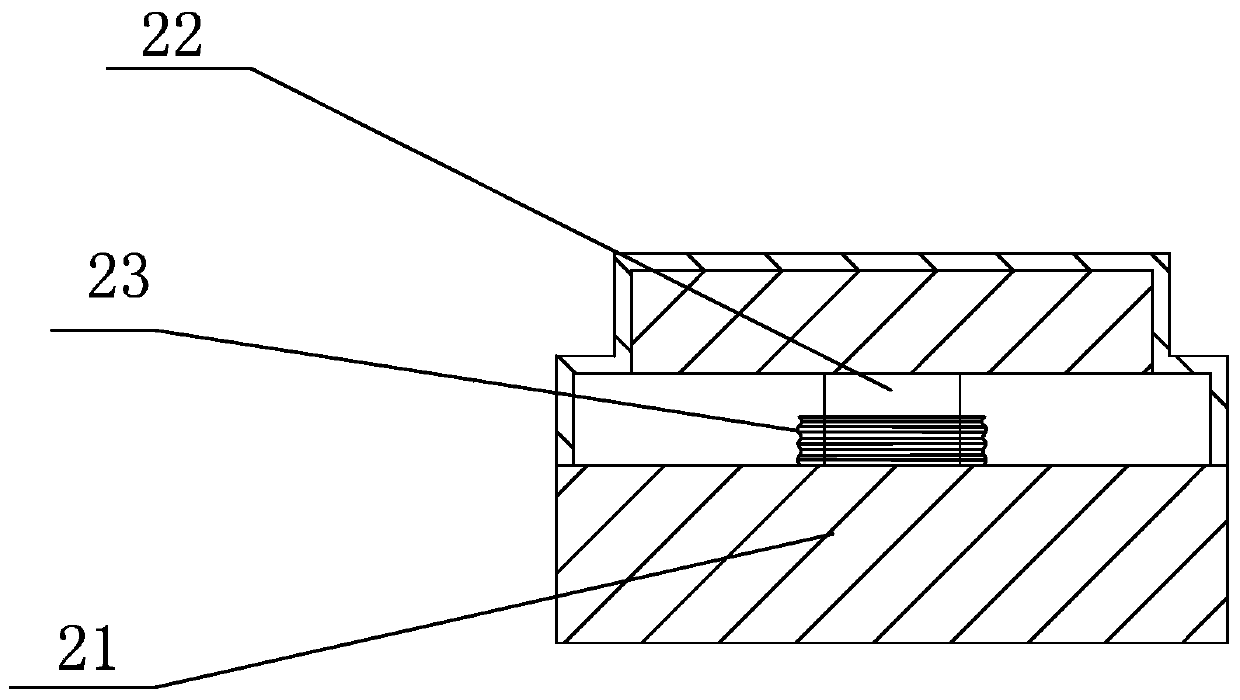

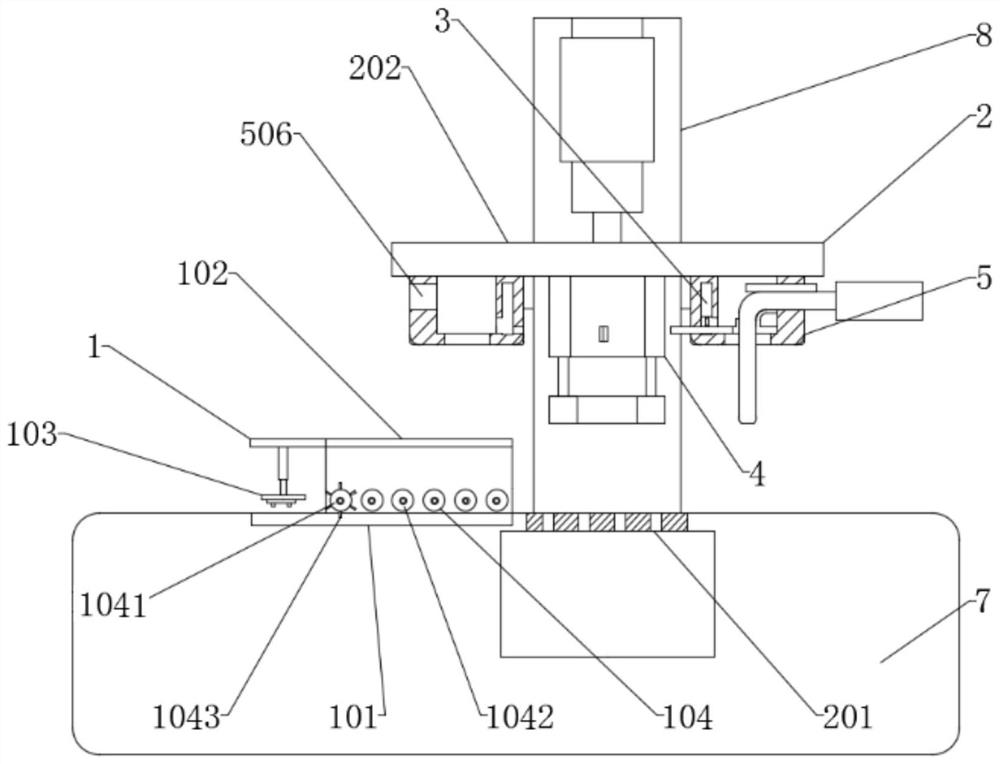

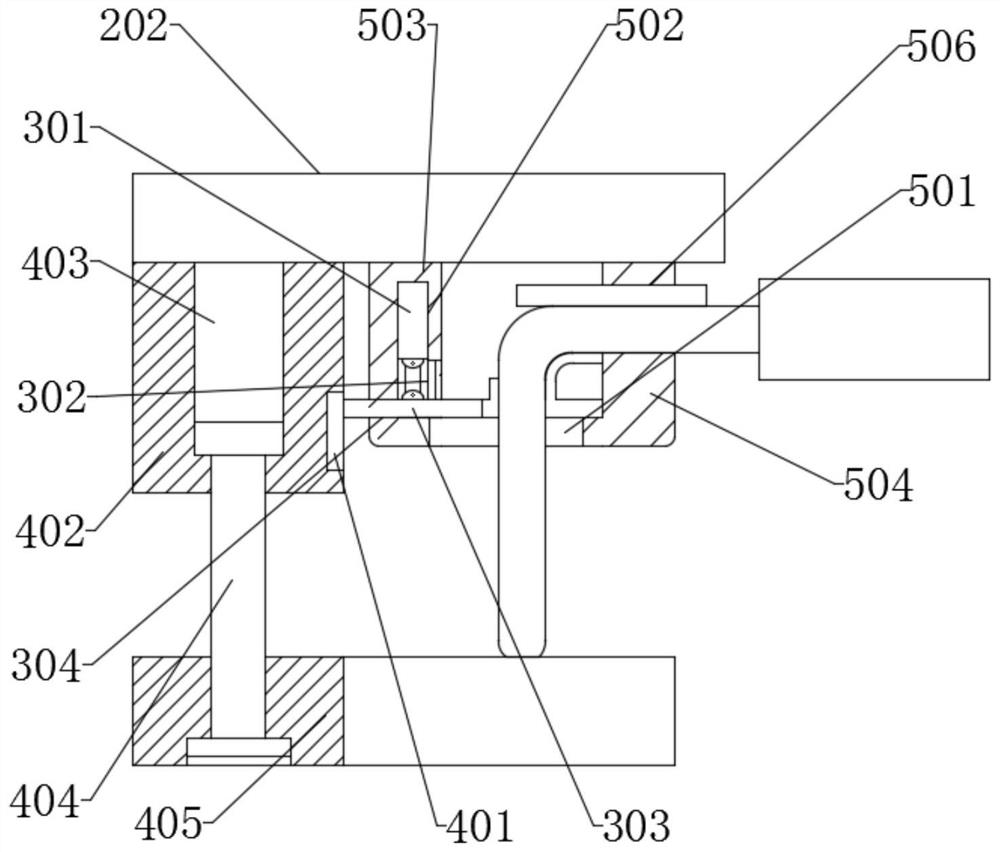

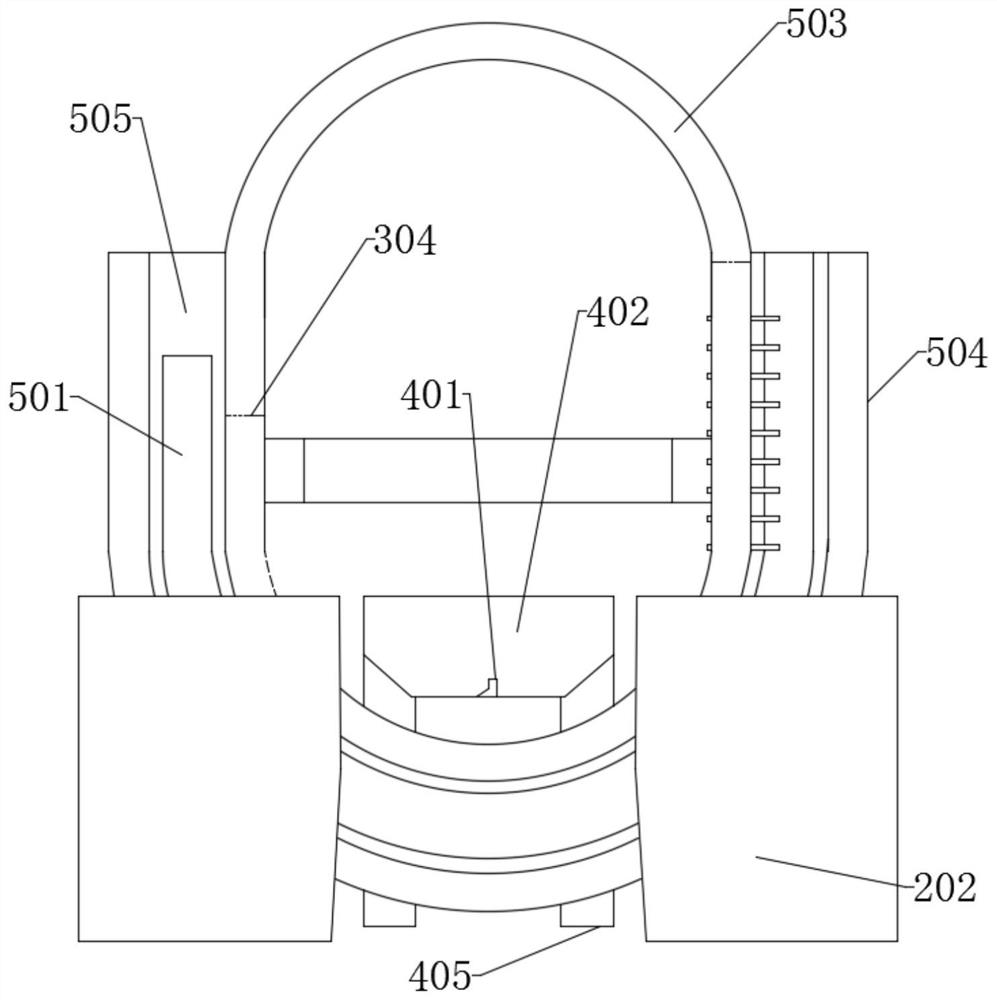

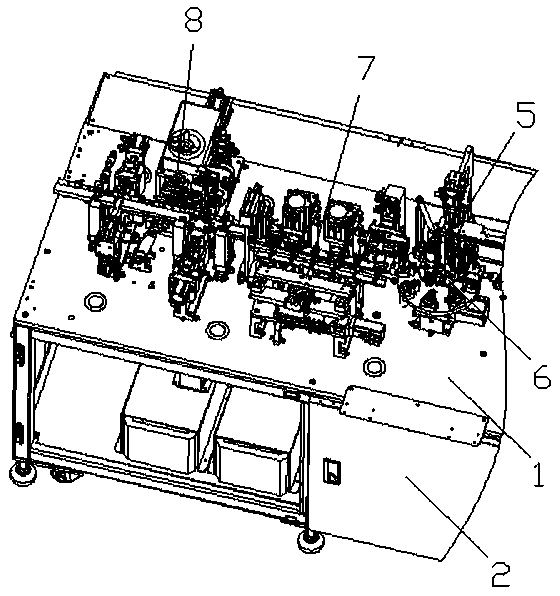

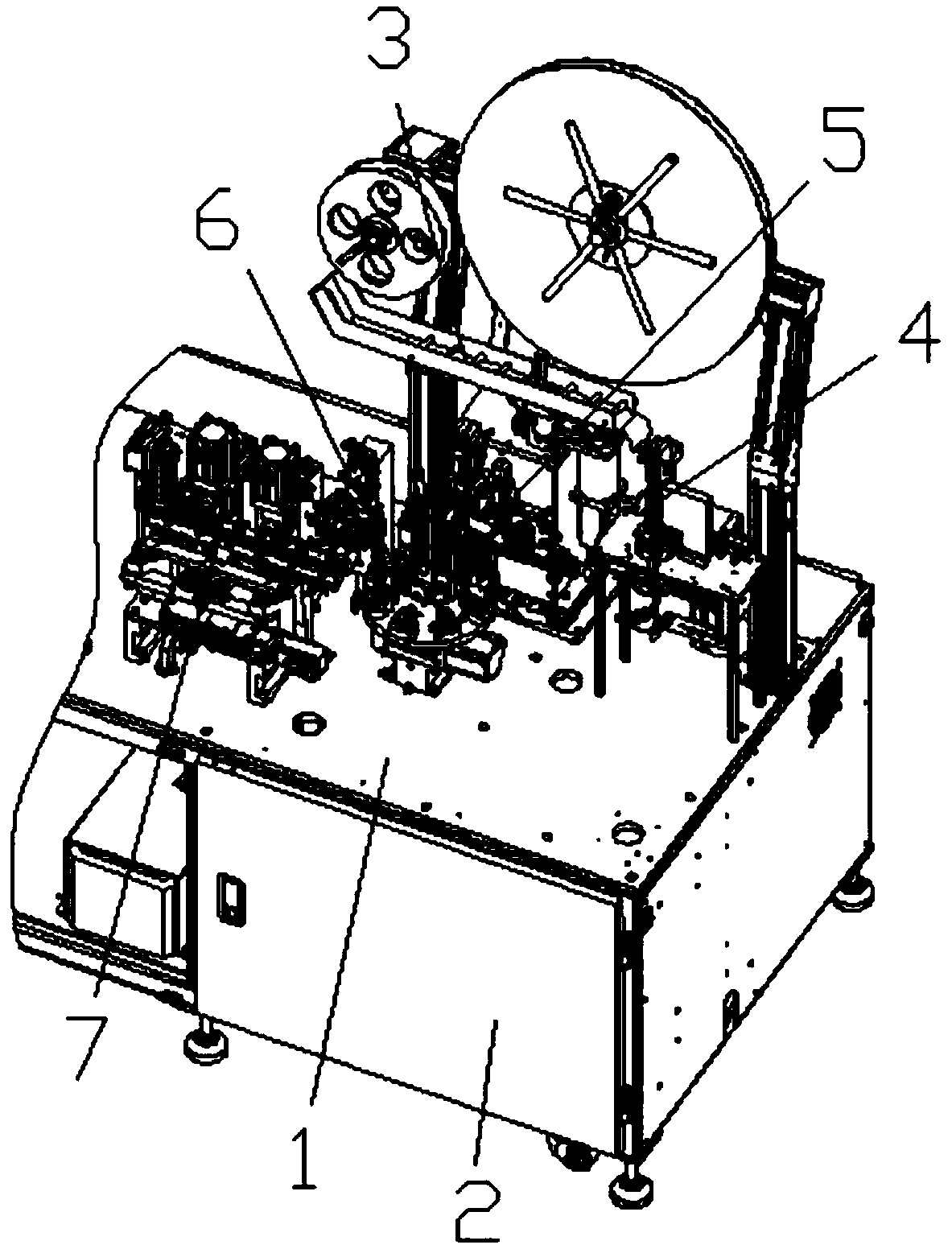

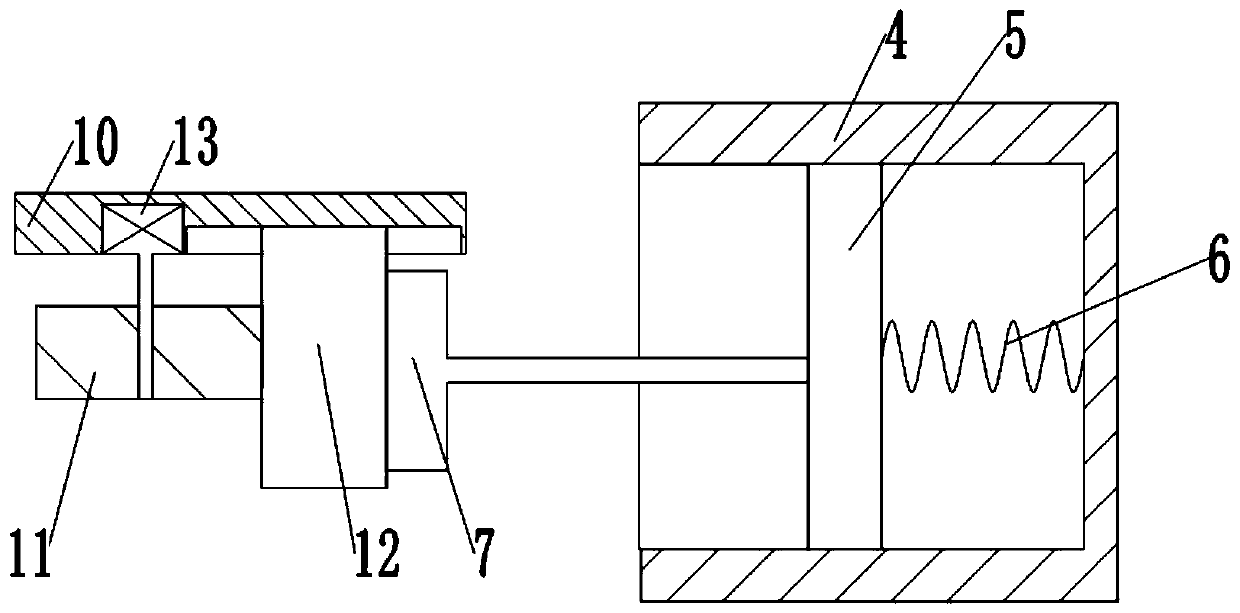

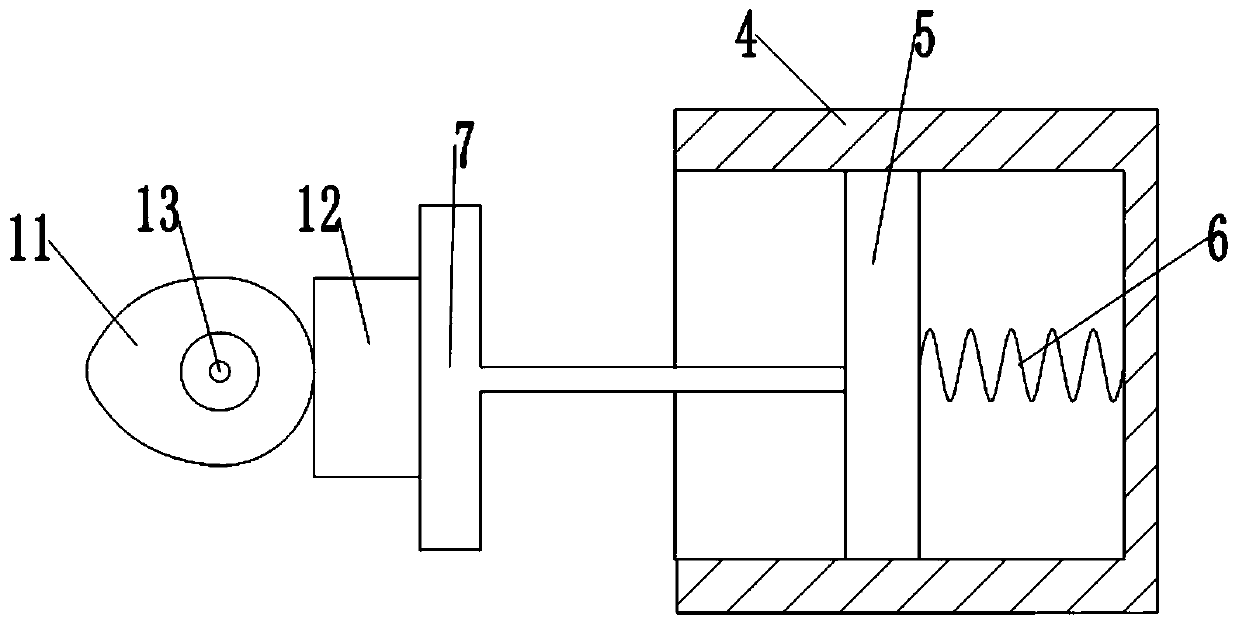

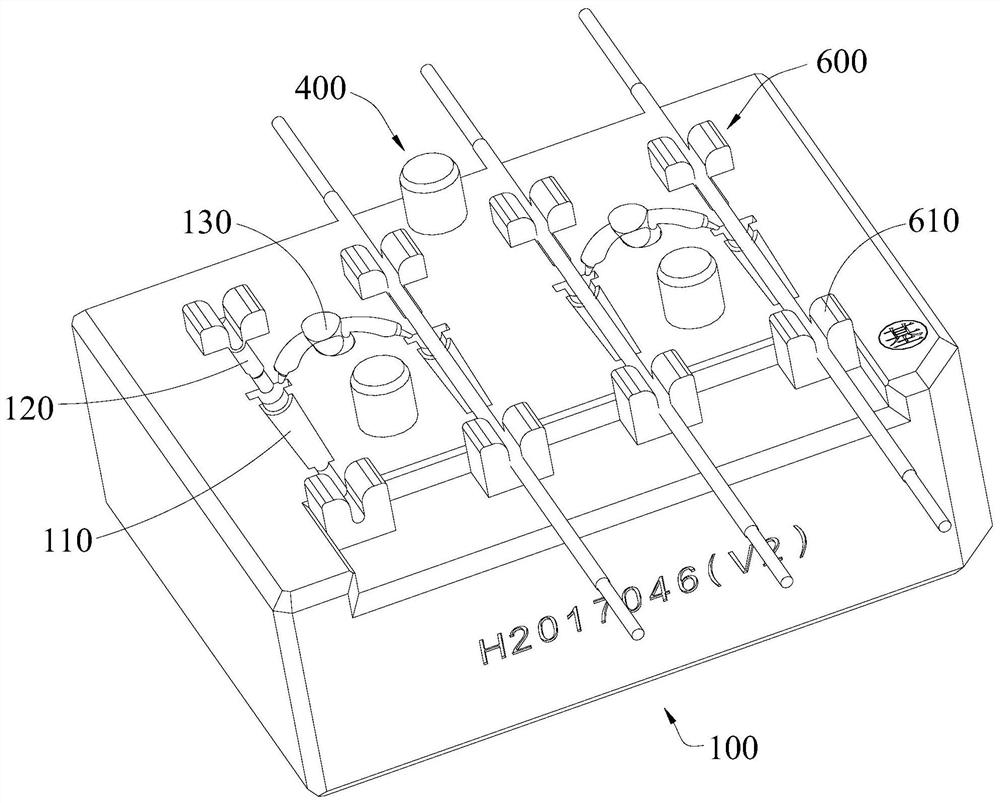

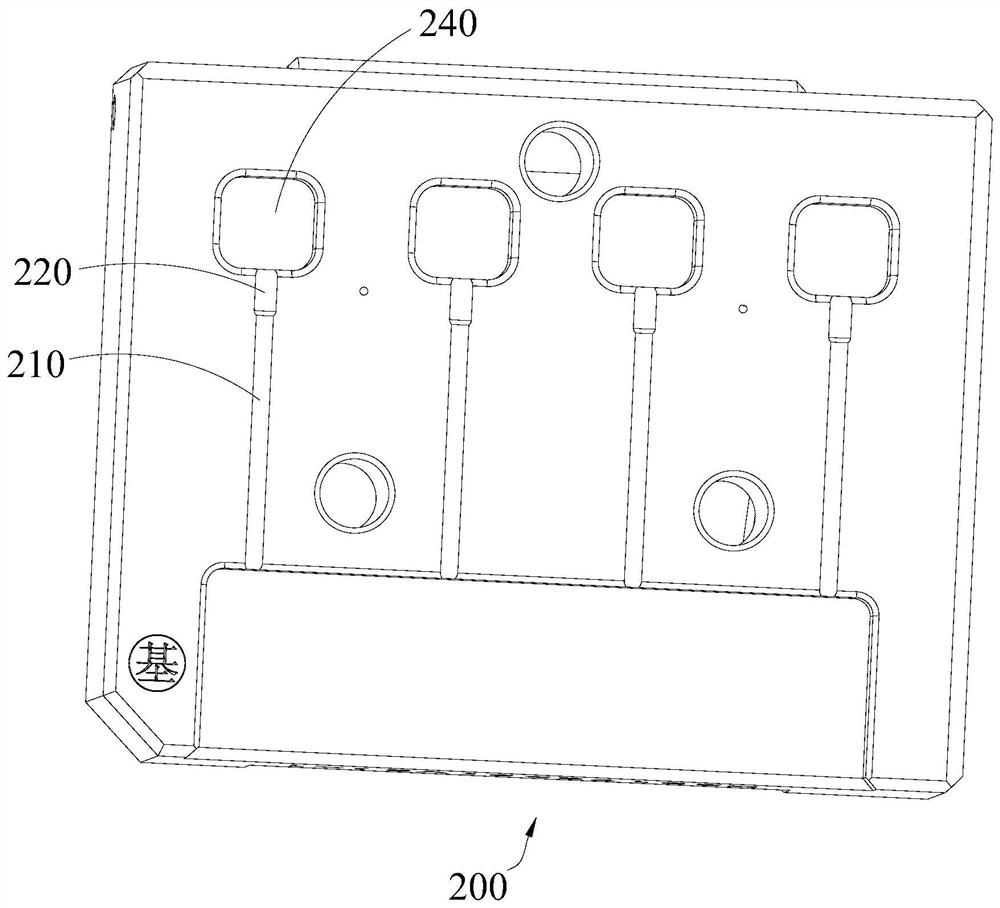

Miniature touch switch assembling machine

ActiveCN112542337AAvoid elasticImprove assembly efficiencyAssembly machinesElectric switchesAssembly machineTouch switch

The invention relates to a miniature touch switch assembling machine. The machine comprises a first guide rail, a base material belt turn-over wheel set and a second guide rail; the first guide rail is provided with a first material belt channel; the base material belt turn-over wheel set is used for turning over a base material belt; and the second guide rail is provided with a second material belt channel on the lower side. The miniature touch switch assembling machine further comprises an elastic sheet feeding device, an elastic sheet base fixing device, an upper cover base clamping device,an upper cover feeding device, and a button feeding device; the elastic sheet feeding device is arranged beside the first guide rail and used for cutting off an elastic sheet from an elastic sheet material belt and placing the elastic sheet on a base; the elastic sheet base fixing device is arranged on the first guide rail and used for fixing the elastic sheet and the base together; the upper cover base clamping device is arranged below the second guide rail. the upper cover feeding device is used for providing an upper cover for the upper cover base clamping device; the button feeding deviceis arranged beside the upper cover base clamping device and is used for providing a button for the upper cover base clamping device; the first guide rail and the second guide rail are provided with afirst material belt feeding device and a second material belt feeding device respectively, wherein the first material belt feeding device and the second material belt feeding device drive the base material belt to move along transmission paths. The assembling machine has the effects of being good in assembling quality and high in assembling efficiency.

Owner:SHENZHEN GANGYUAN MICRO KEY TECH CO LTD

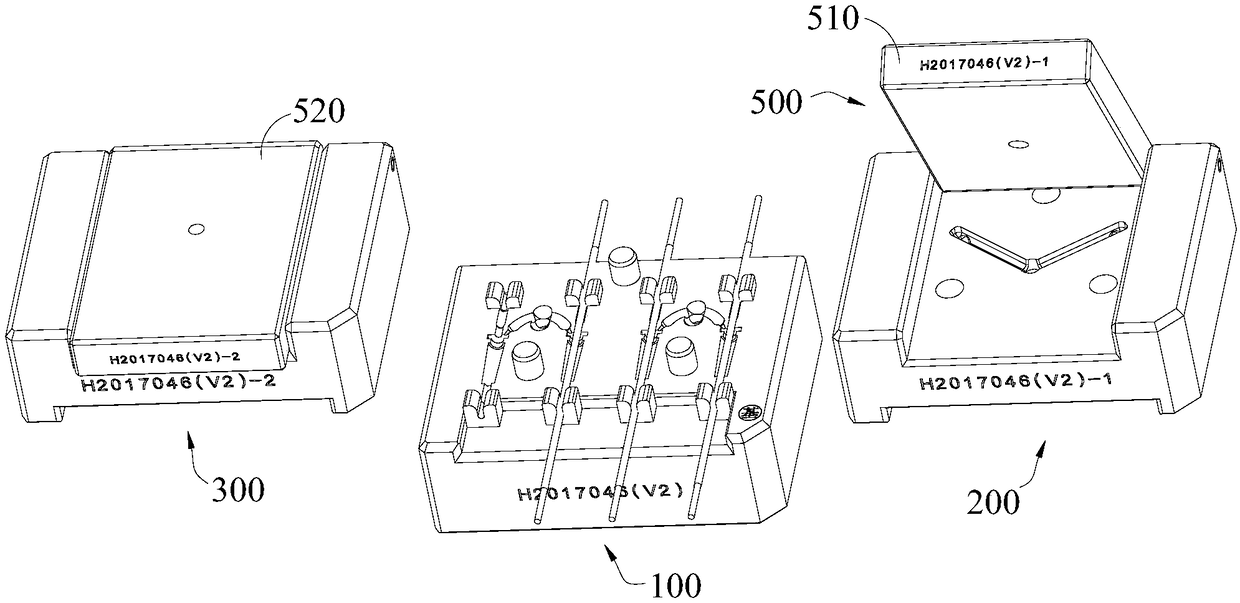

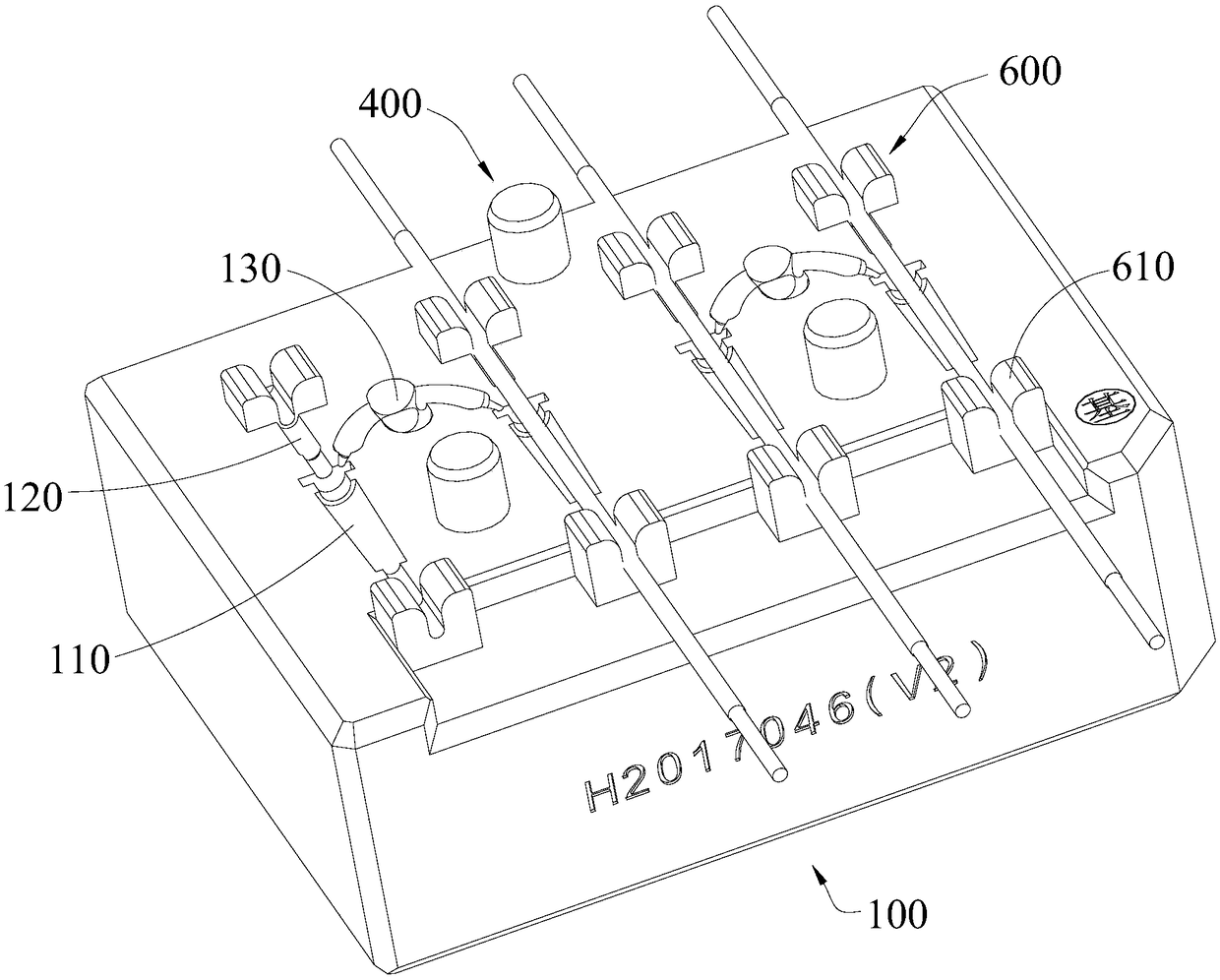

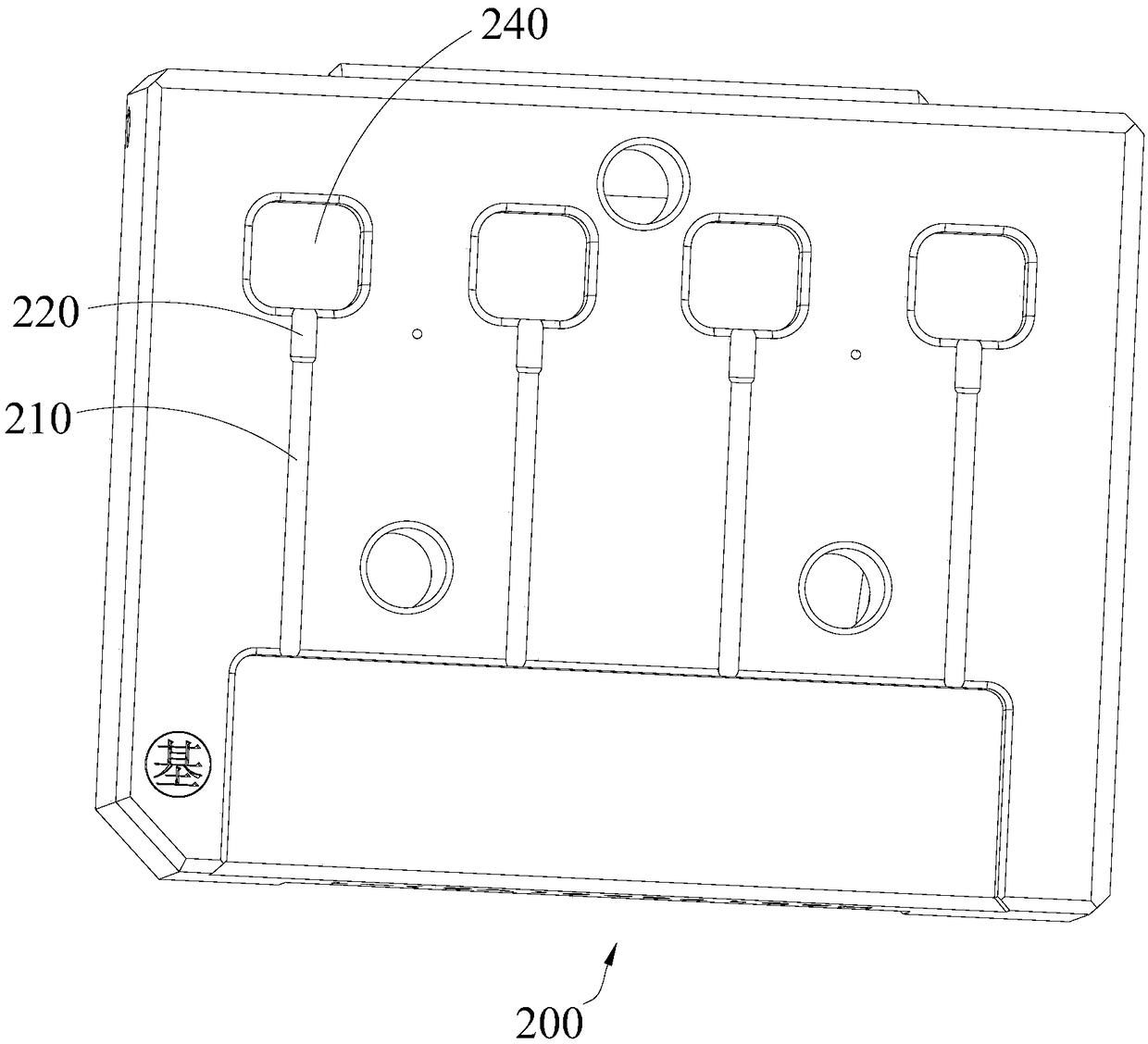

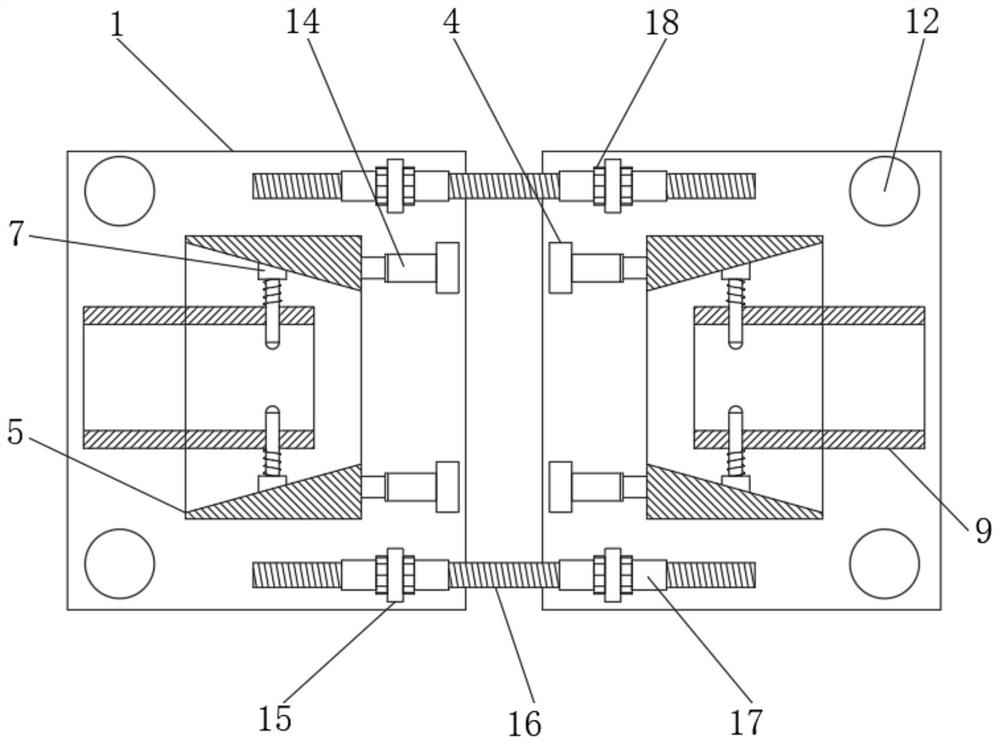

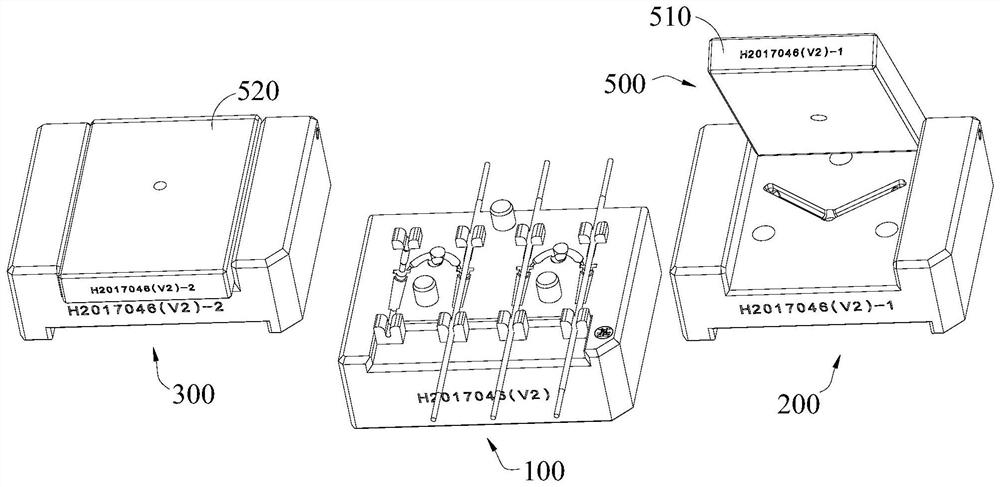

Ear handle outer mold injection molding module

ActiveCN109454826AIncrease productivityImprove injection molding efficiencyInjection molding machineMaterials science

The invention discloses an ear handle external mold injection molding module. The injection molding module comprises an injection molding bottom mold, an injection molding lower mold and an injectionmolding upper mold, wherein a first ear handle forming cavity and first position avoiding wire grooves are formed in the injection molding bottom mold, and the first ear handle forming cavity is in communication with the first avoiding wire grooves; the injection molding lower mold is provided with a wire containing half groove and second position avoiding wire grooves, and the wire containing half groove is in communication with the second position avoiding wire grooves; the injection molding upper mold is provided with a second ear handle forming cavity and third position avoiding wire grooves, and the second ear handle forming cavity is in communication with the third position avoiding wire grooves; when the injection molding lower mold is used for covering the injection molding bottommold, the first ear handle forming cavity is enabled to be in communication with the wire containing half groove; and when the injection molding upper mold is used for covering the injection molding bottom mold, the first ear handle forming cavity is enabled to be in communication with the second ear handle forming cavity. According to the injection molding module, one injection mold can be saved,and the cost of injection molding can be reduced. The situation of incomplete injection molding can also be avoided, so that the quality of the earphone wire can be improved, and the production efficiency of the ear handle injection molding is further improved.

Owner:雅刚电子(惠州)有限公司

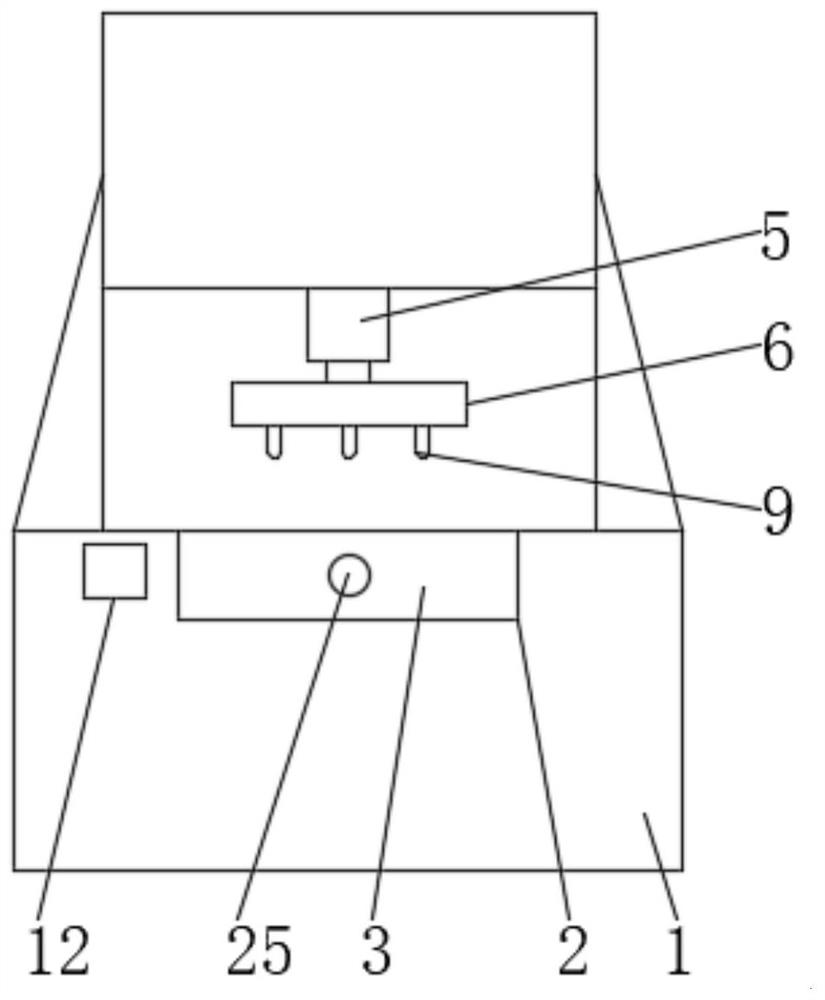

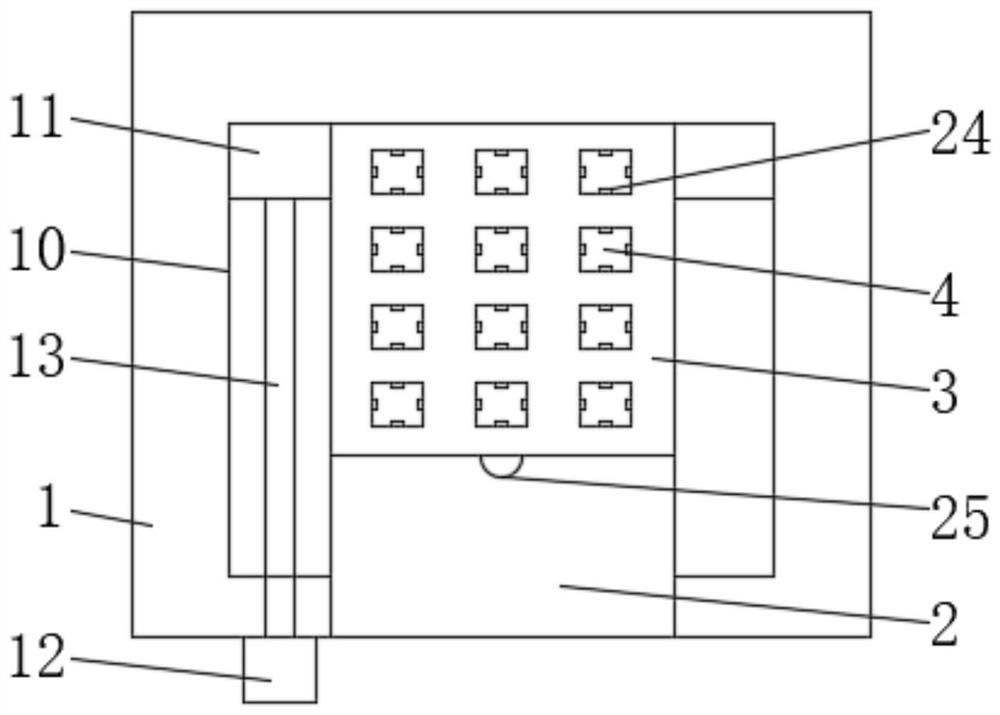

Touch control chip simulation pressing test jig

InactiveCN112881891AEasy to put inEasy to take outElectronic circuit testingComputer hardwareTest efficiency

The invention discloses a touch control chip simulation pressing test jig which comprises a test machine body. A sliding groove is formed in a machine table of the test machine body, a chip groove is formed in a plate, a buffer groove is formed in a lifting plate, a lifting block is arranged in the buffer groove in a sleeved mode, and a probe is installed on the lifting block. The chip can be conveniently put in or taken out by controlling the plate to move out of or move into the sliding groove; by controlling the magnetism of the electromagnet, the pressing rod can be controlled to be retracted into the cavity or moved out of the cavity, so that one end of the pressing rod can be conveniently controlled to press the chip, the chip is fixed in the chip groove, and the situation that the test is influenced by movement and dislocation of the chip is avoided; the laser lamp emits light rays along the probe to irradiate the chip, so that the probe and the chip can be positioned, and the condition that the probe and the chip are staggered is avoided; the plurality of probes are controlled to test the chips in the plurality of chip grooves, so that the test efficiency can be improved; and the first spring is used for buffering, so that the condition that the chip is crushed can be avoided.

Owner:张雪

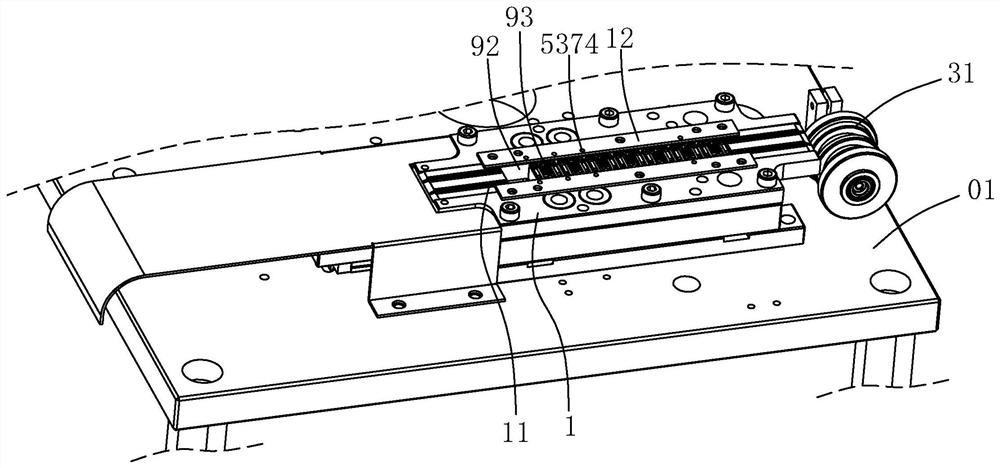

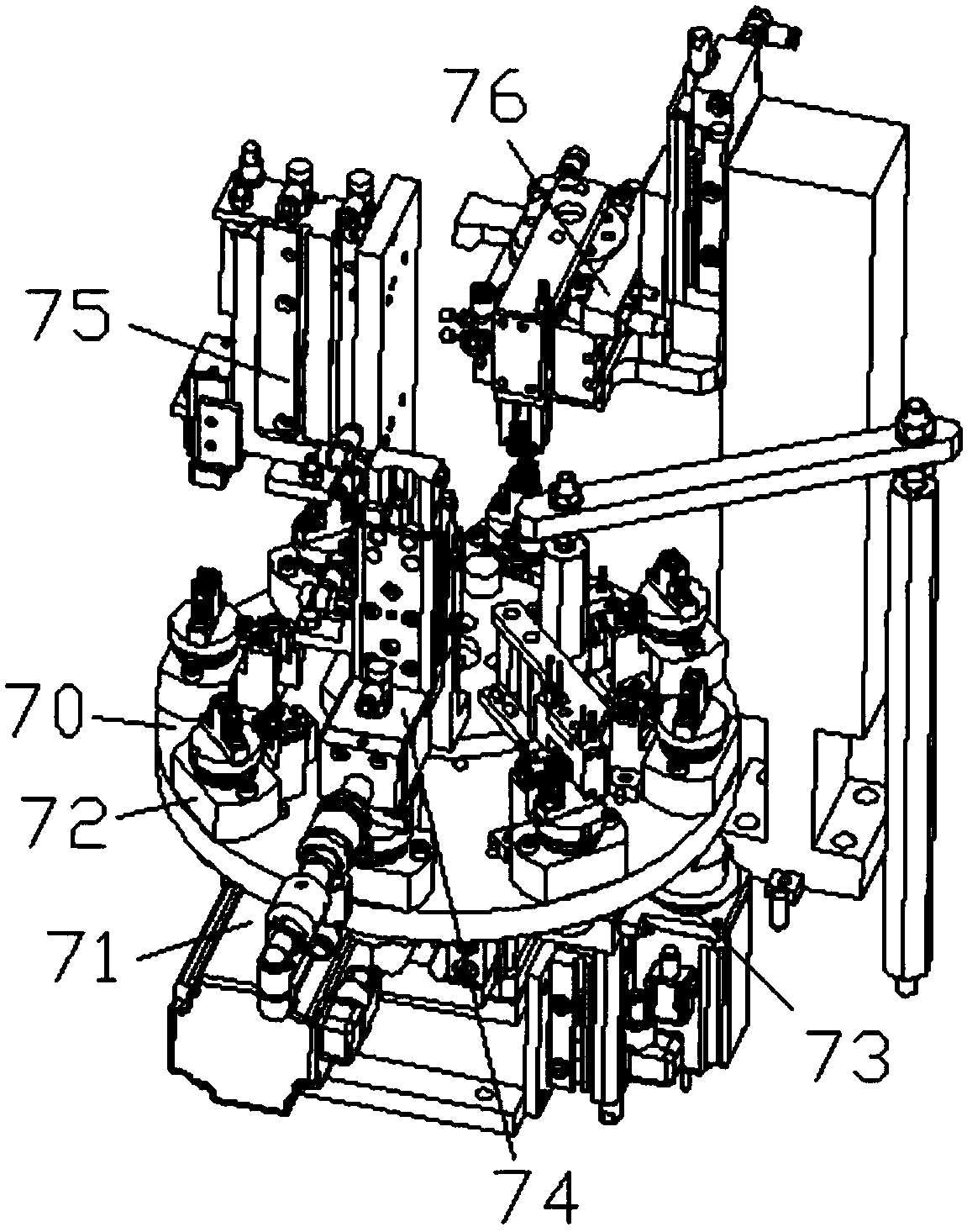

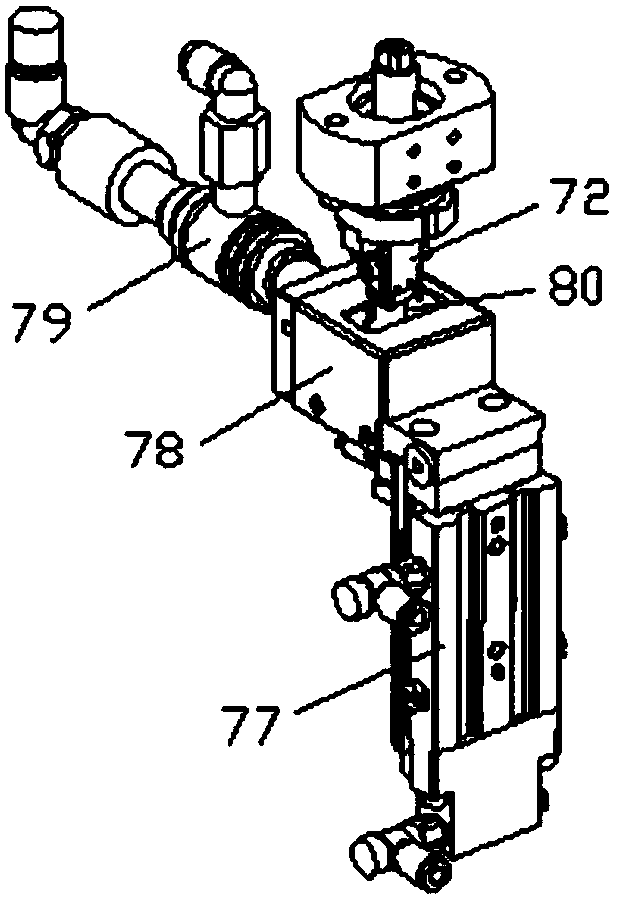

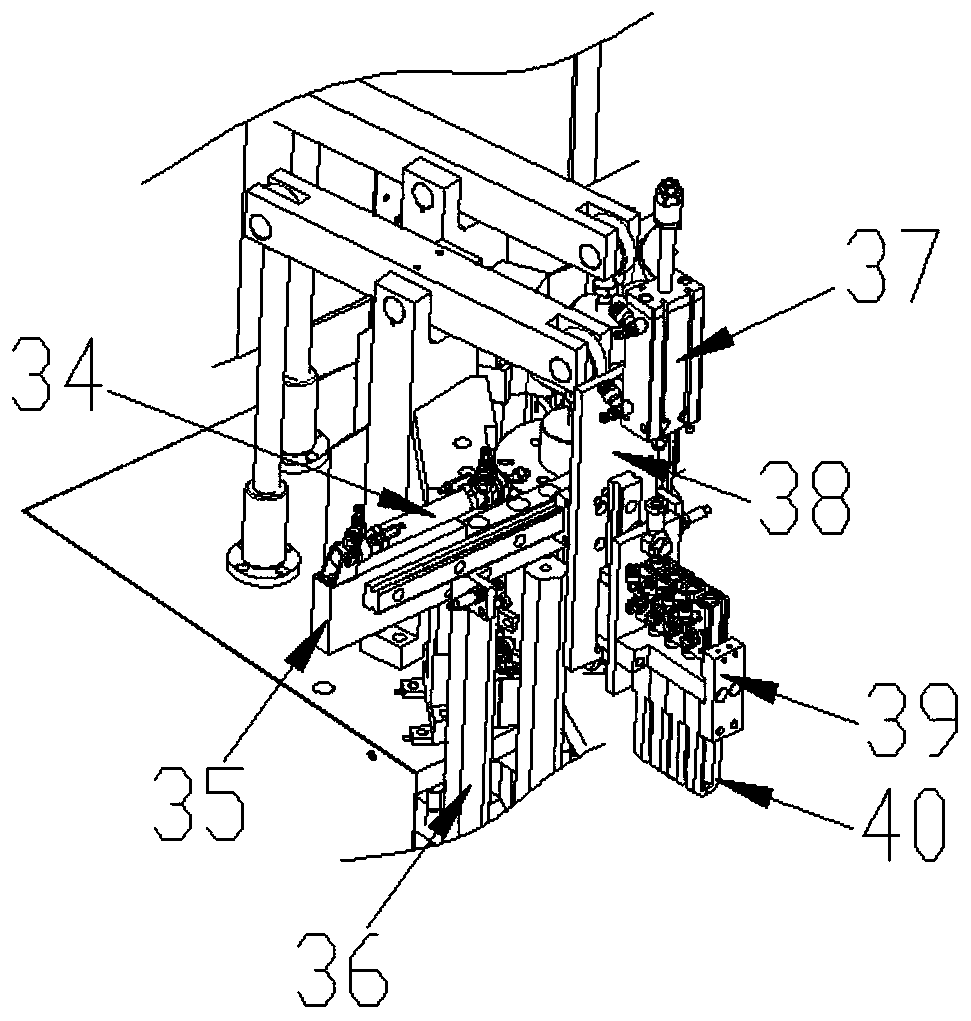

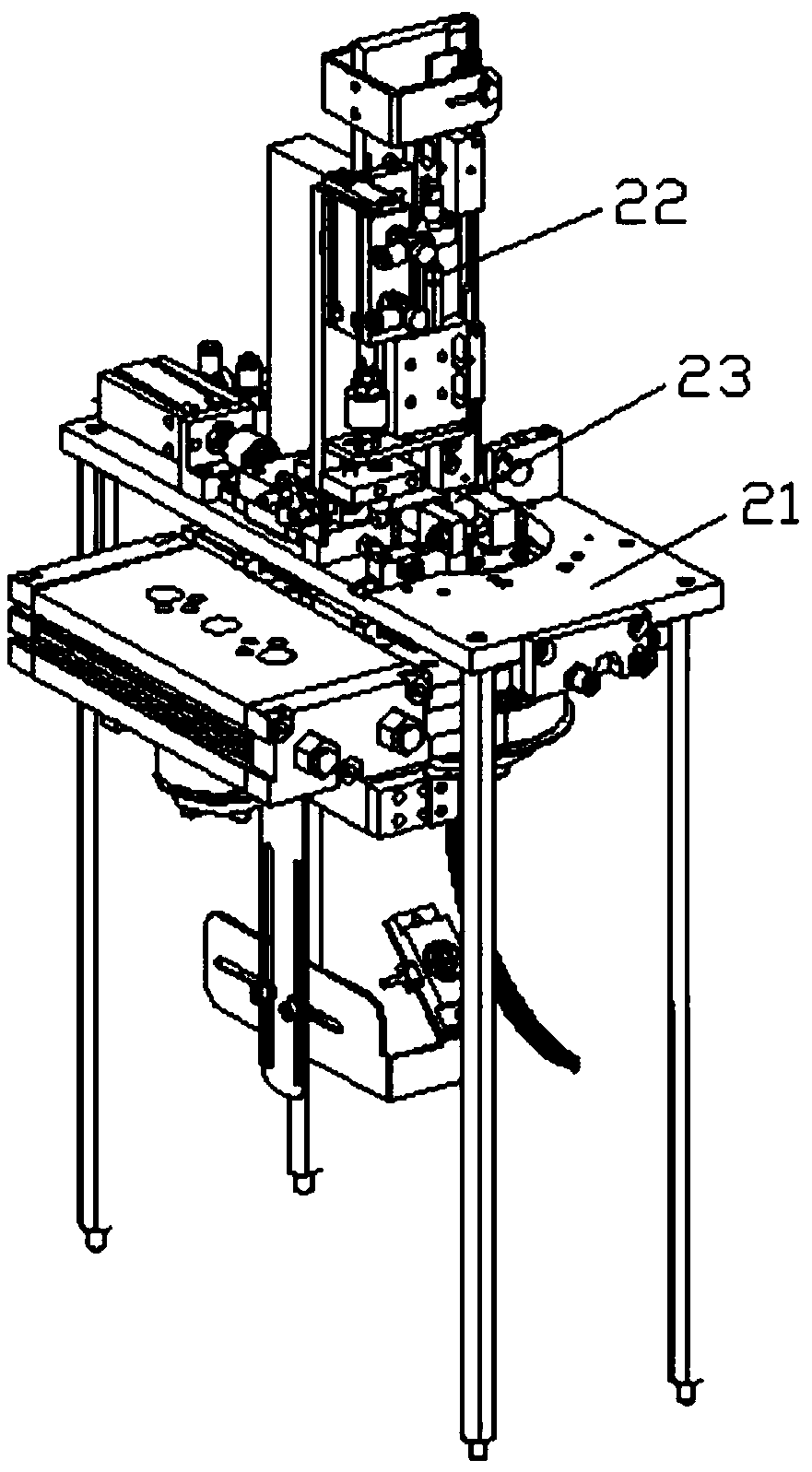

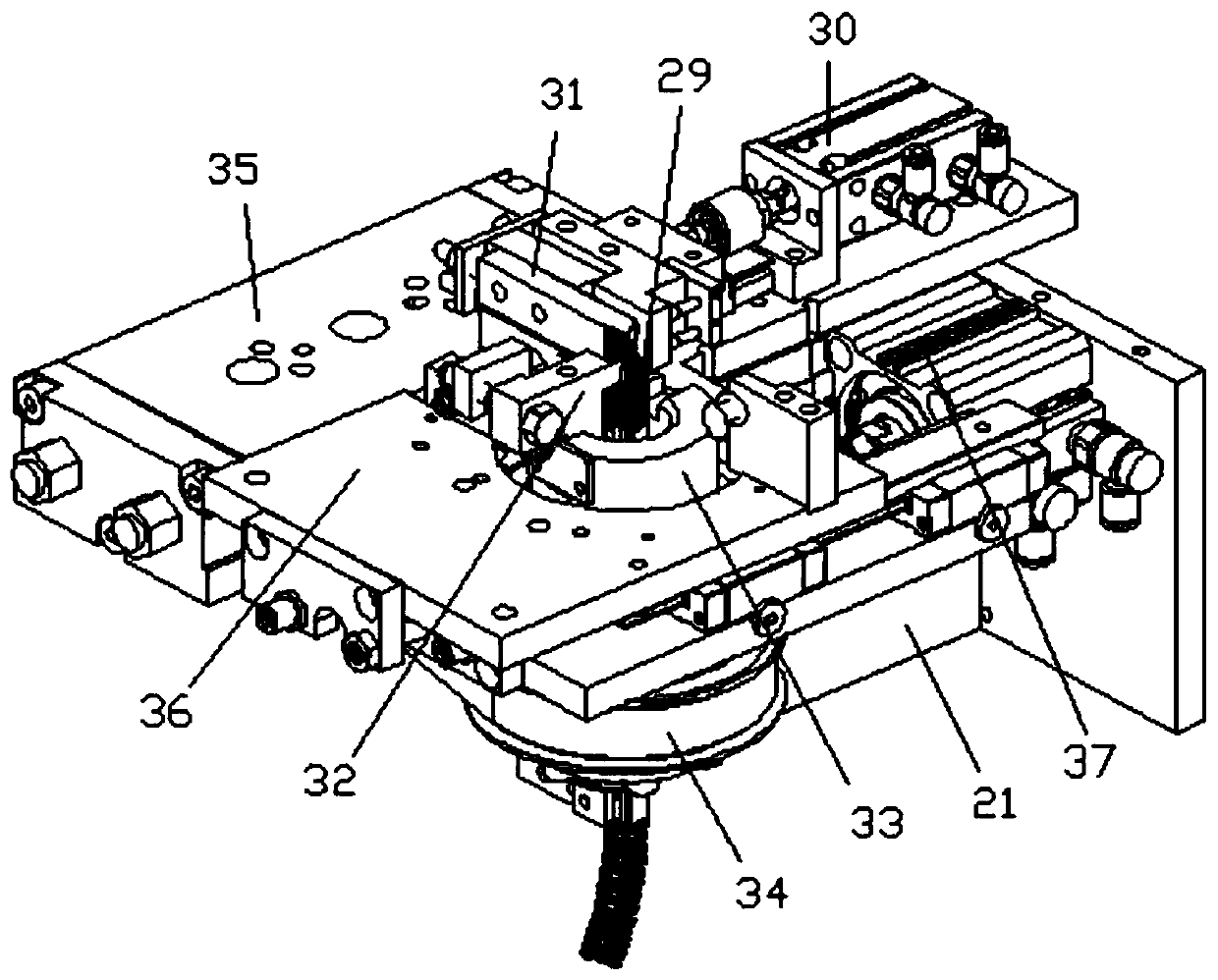

Locking plate assembling machine for connector

ActiveCN108110591AImplement continuous insertionGuaranteed accuracyContact member assembly/disassemblyEngineeringCam

The invention relates to a locking plate assembling machine for a connector. The locking plate assembling machine comprises a locking plate inserting mechanism. The locking plate inserting mechanism comprises a locking plate inserting conveying slot and a locking plate inserting feeding device. The middle of the locking plate inserting conveying slot cooperates with a locking plate clamping material overturning device. The rear side of a clamping material overturning block is provided with a vertically extending locking piece conveying device. A locking plate clamping device is arranged abovethe side portion of the locking plate conveying device. A locking plate carrier tape cutting device and a locking plate pressure device are arranged below the side portion of the locking plate conveying device. A locking plate inserting device is disposed behind the locking plate conveying device. The purpose of the invention is to provide a locking piece assembling machine for a connector. A locking plate is made into a carrier tape and is conveyed vertically by the locking plate conveying device. The same cam drive device is configured to drive the locking plate clamping device, the lockingplate carrier tape cutting device, the locking plate pressure device, the locking plate inserting device push the locking plate forward and backward, and can achieve continuous insertion of the locking plate in cooperation with the locking plate inserting conveying slot. The locking plate assembling machine can ensure the accuracy of inserting the locking plate, greatly improves the efficiency ofinserting the locking plate.

Owner:苏州市相城区黄桥工业园经济发展有限公司

Automatic film sealing device for mobile phone screen pre-delivery

InactiveCN109531984AFit tightlyTo achieve the purpose of heat sealing filmHydraulic cylinderEngineering

The invention discloses an automatic film sealing device for mobile phone screen pre-delivery and relates to the technical field of mobile phone screens. The automatic film sealing device comprises abox body. The upper surface of the inner wall of the box body is fixedly connected with the upper surface of a shell through a hydraulic cylinder. First sliding blocks are fixedly connected to the left side face and right side face of the shell correspondingly. First sliding grooves are formed in the left side face and right side face of the inner wall of the box body correspondingly. The first sliding blocks are slidably connected in the first sliding grooves. Second sliding grooves are formed in the left side face and right side face of the inner wall of the shell. Second sliding blocks areslidably connected to the inner walls of the second sliding grooves. The opposite surfaces of the two second sliding blocks are fixedly connected with the left side face and right side face of the shell correspondingly. By means of the automatic film sealing device for mobile phone screen pre-delivery, due to the joint efforts of a spring, a shell, a U-type plate, a first rotating shaft, an electromagnetic heating roller, a second rotating shaft, a rotating roller and a scraping plate, under the action of different working procedures, the film sealing effect is better, the success rate is higher, and the production can be finished more efficiently.

Owner:湖南宽洋科技有限公司

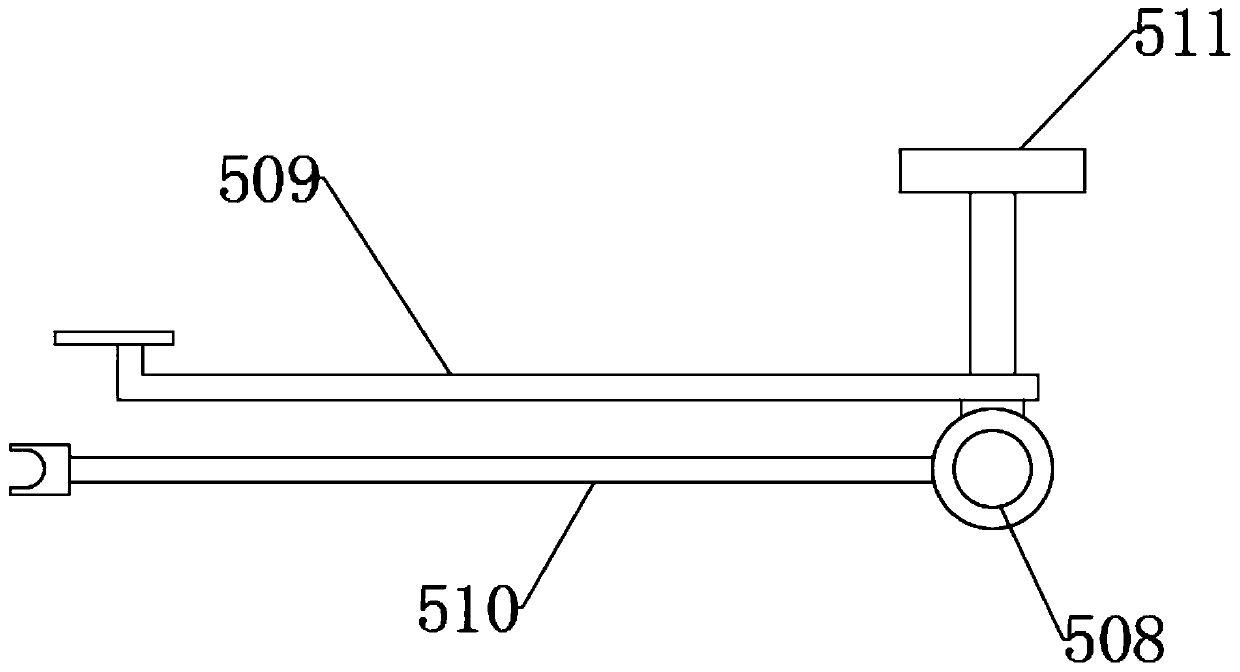

Auxiliary tool for installing synchronous wheel on servo motor

InactiveCN110289736ARelieve pressureHas a buffering effectManufacturing dynamo-electric machinesMetal working apparatusManipulatorPotential energy

The invention discloses an auxiliary tool for installing a synchronous wheel on a servo motor, and the auxiliary tool comprises a base, wherein the upper side wall of the base is connected with a mounting plate through a supporting device, and a sliding cavity is formed in the mounting plate; the inner wall of the sliding cavity is connected with a moving plate through a sliding device, and the moving plate is connected to the bottom side wall of the mounting plate in a sliding mode. According to the invention, when a telescopic rod is lengthened to press a telescopic block, the telescopic block presses a manipulator body downwards, and the manipulator body can press downwards and clamps the synchronous wheel; at the moment, the telescopic rod can continue to press a fixing plate downwards, and a rotating rod is pressed down; therefore, a first spring is lengthened, and the pressure of the telescopic rod is converted into the elastic potential energy of the first spring, so that the pressure of the telescopic block on the manipulator body is reduced, and the manipulator body is buffered, thereby avoiding the situation that a motor shell is crushed by the mechanical arm body due to overlarge downward pressure as much as possible, and avoiding the waste of resources.

Owner:扬州格莱特电动工具有限公司

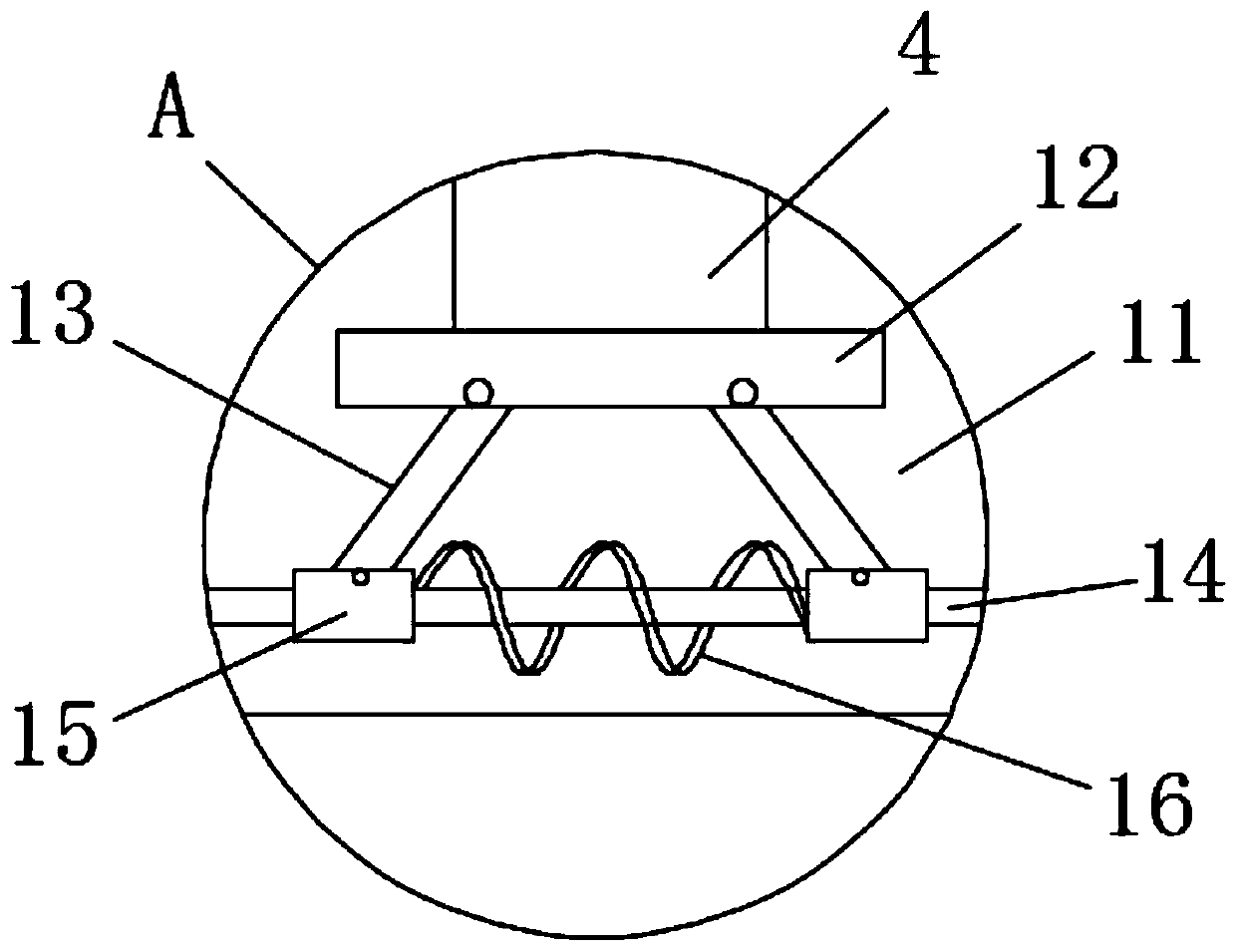

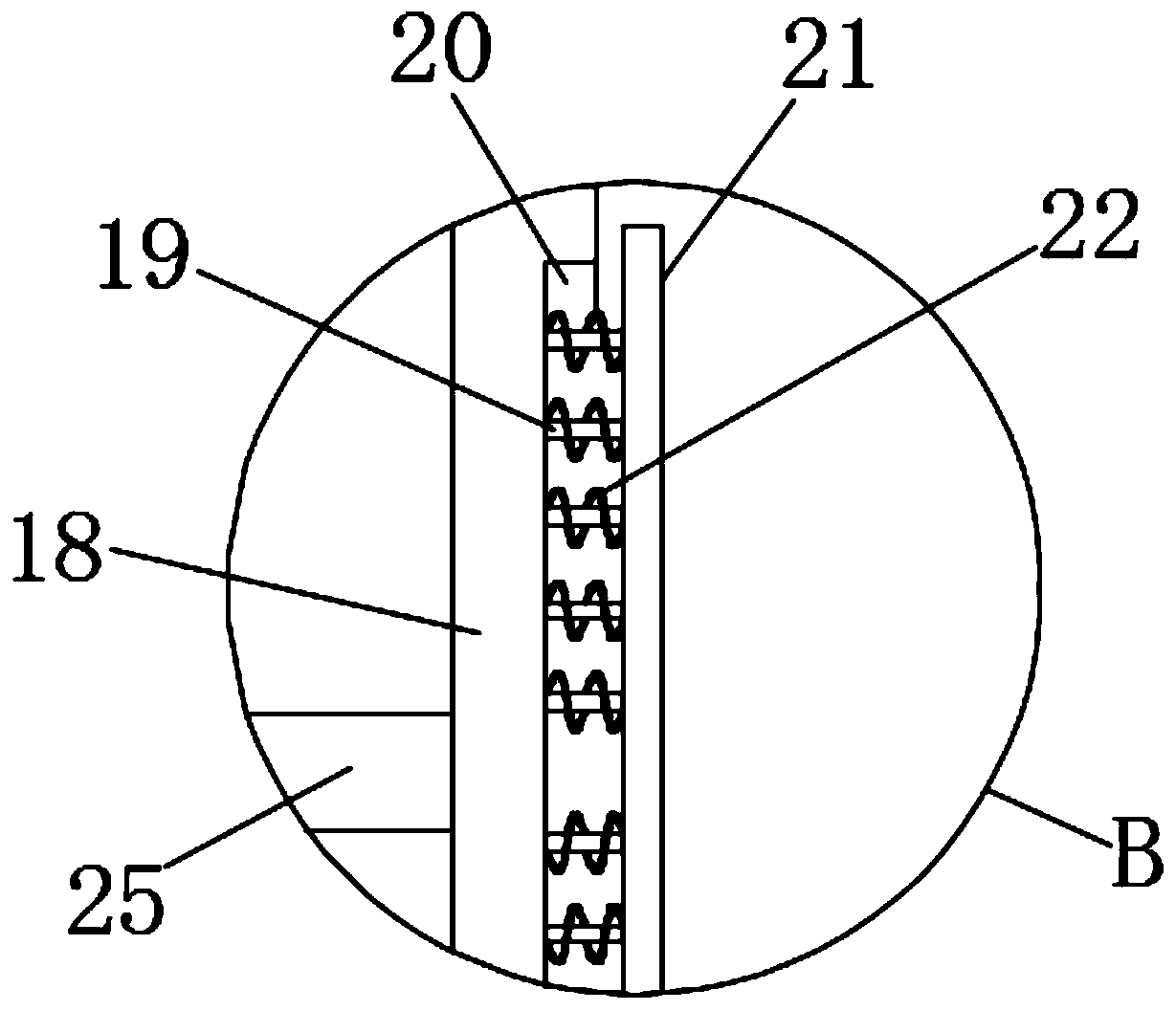

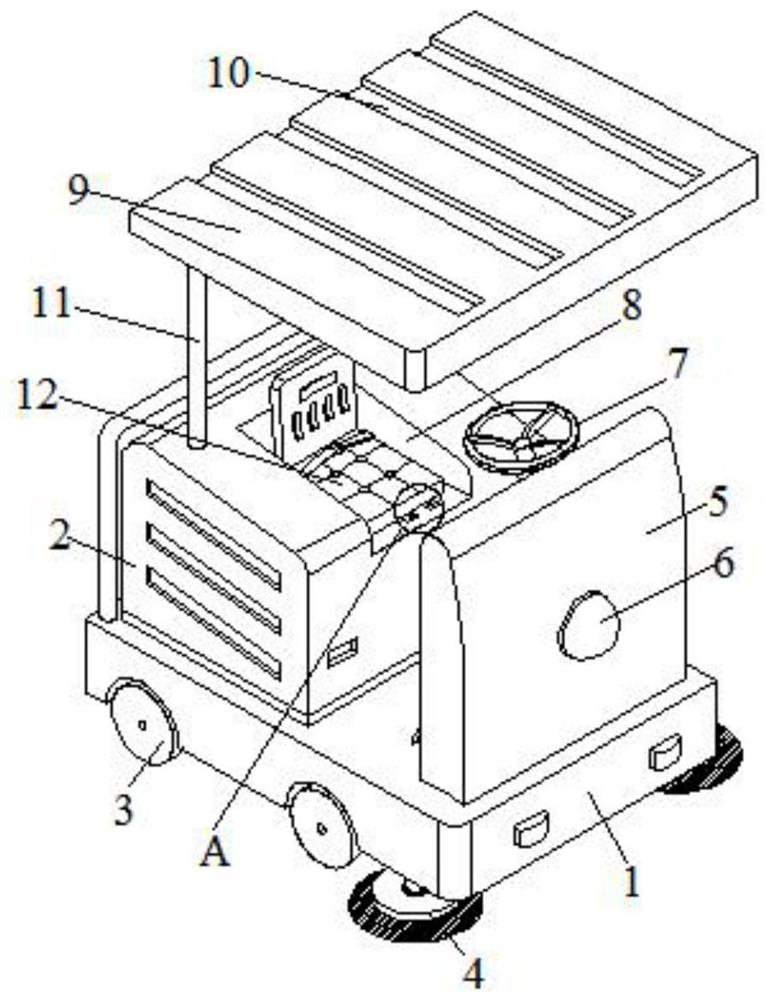

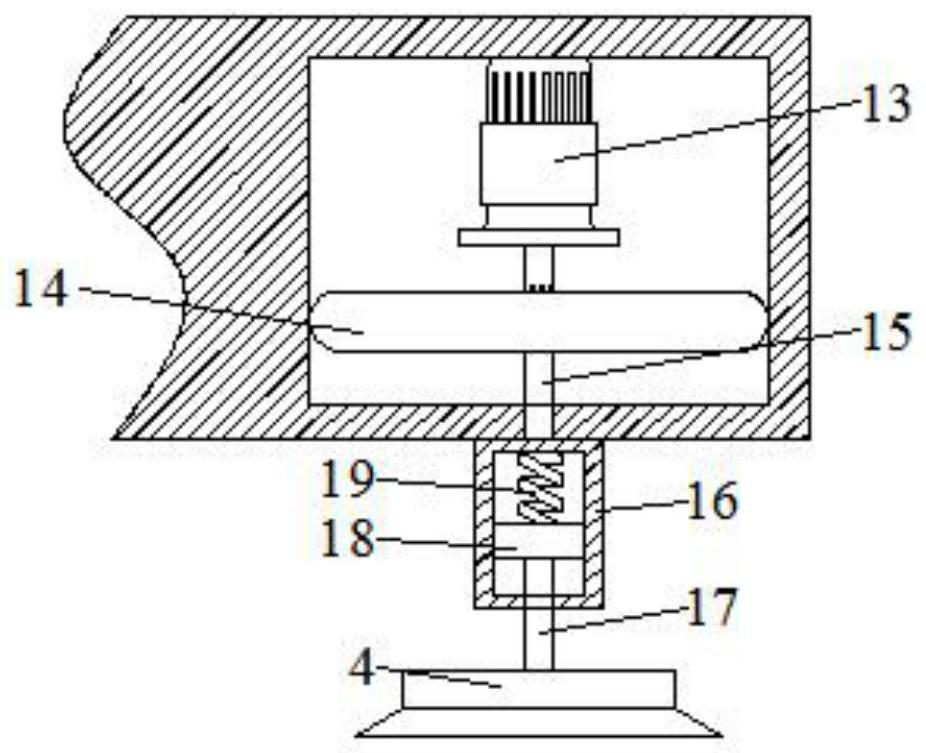

Automatic steam sweeper

InactiveCN113062252AAvoid non-adjustable disadvantagesEasy to useRoad cleaningEngineeringStructural engineering

Owner:佳威盛电子(深圳)有限公司

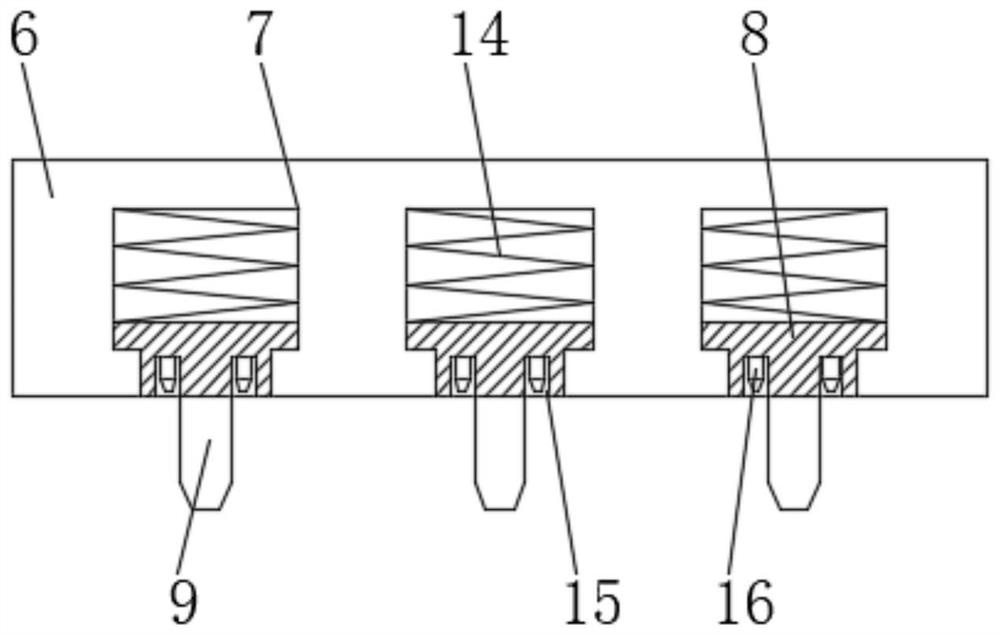

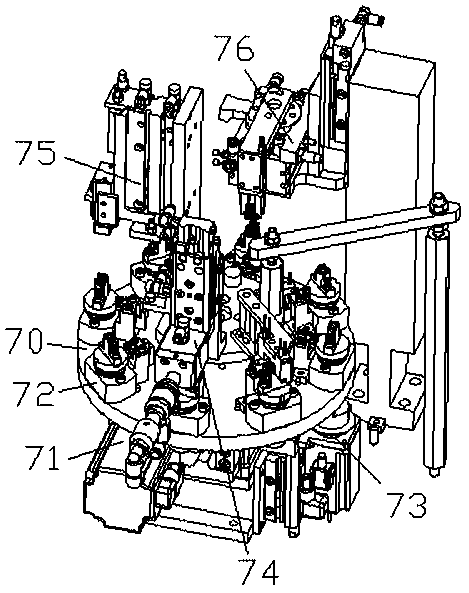

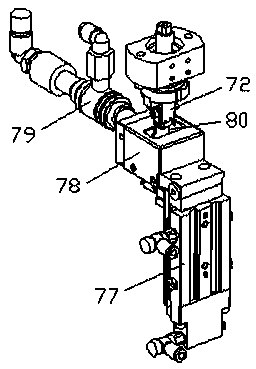

Protective cap loading device for automatic injection needle assembling system

PendingCN109702481AGuaranteed to press firmlyAvoid crushed situationsAssembly machinesInjections needleBiomedical engineering

The invention discloses a protective cap loading device for an automatic injection needle assembling system. The protective cap loading device comprises a third rotary table which is rotationally connected with a table board of the automatic injection needle assembling machine; the third rotary table is fixedly provided with a plurality of groups of protective sleeve needle connecting through holegroups in an annular array; each group of the protective sleeve needle connecting through hole groups comprises a plurality of protective sleeve needle connecting through holes, close to the edge ofthe third rotary disc; the diameter of each protective sleeve needle connecting through hole is smaller than the maximum outside diameter of a protective sleeve; each protective sleeve needle connecting through hole can be inserted into the protective sleeve; and the position, on the outer sides of the protective sleeve needle connecting through holes on the third rotary table, on the table boardof the automatic injection needle assembling machine is sequentially provided with a protective sleeve needle connecting mechanism, an empty detection mechanism, a protective cap loading mechanism, aprotective cap pressing mechanism and a finished product clamping mechanism. For the protective cap loading device, by adopting the rotary table, the rejection rate is reduced, the efficiency is high,and the precision of a dropping position of an injection needle after turning back can be guaranteed. The protective cap loading device solves the problem that a protective cap cannot be automatically pressed in the past, breaks down the technical barrier in the prior art and can even realize the automatic scalding of the protection cap.

Owner:CAINA TECH CO LTD

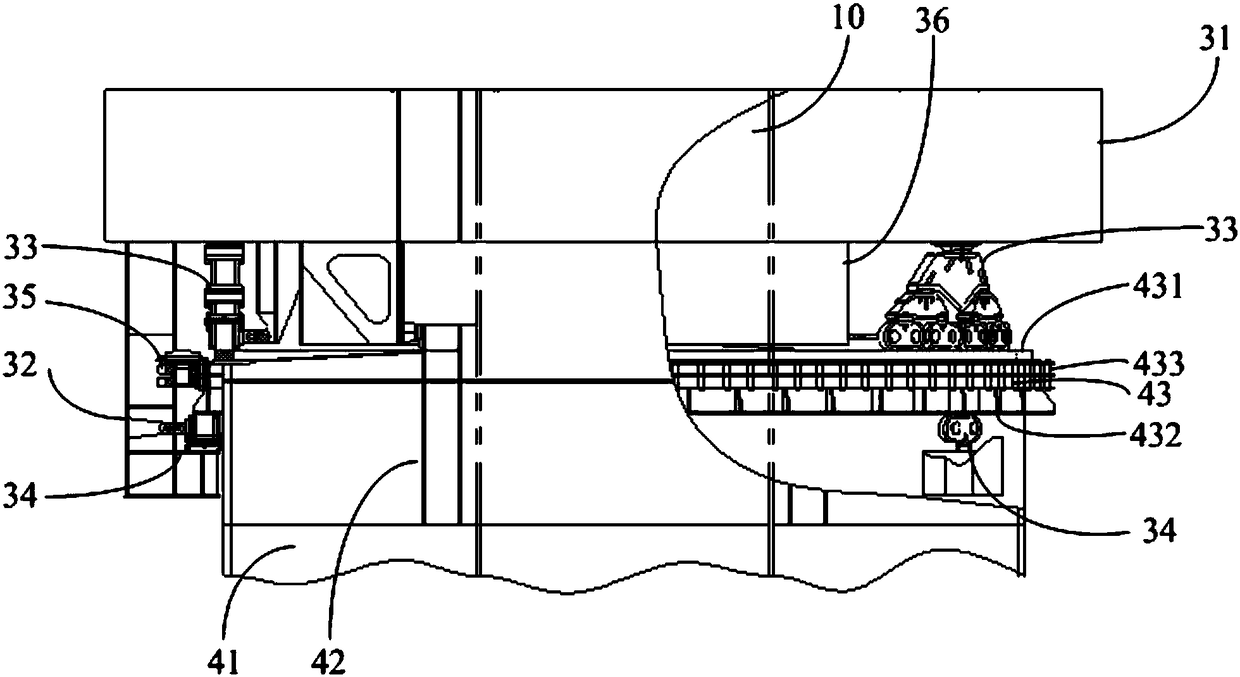

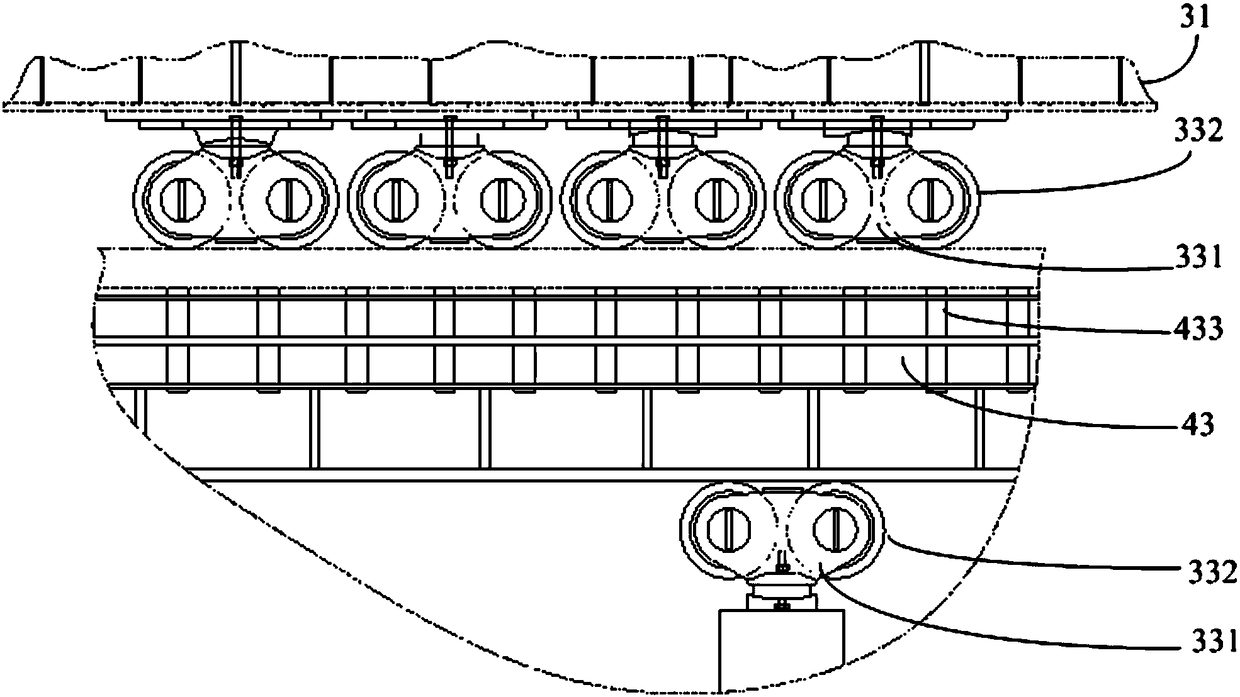

Automatic assembly production line of heat pipe radiator

ActiveCN112475062AEasy to operatePrecise alignmentMetal-working feeding devicesHeat exchange apparatusProduction linePunching

The embodiment of the invention discloses an automatic assembly production line of a heat pipe radiator. The automatic assembly production line of the heat pipe radiator comprises a workbench and a force unloading conveying mechanism which is arranged at the end part of the workbench and is used for feeding radiating fins, a fixing frame is arranged on the side surface of the workbench, and the fixing frame is provided with a pipe feeding positioning mechanism used for fixing a heat pipe and fixing the radiating fins on the side wall of the heat pipe. According to the production line, througha fixing block, a clamping and fixing device and a circulating frame, the operation of rapidly installing multiple heat pipes on a punching device can be achieved, so that the assembling efficiency isimproved; and during implementation, the heat pipe is installed on the fixing block and fixed through the clamping and fixing device, then the fixing block is clamped in the circulating frame, then the fixing block and the heat pipe are made to move circularly in the circulating frame by driving a positioner, when the heat pipe moves to the position right over an assembling base, the positioner is driven to fix the position of the fixing block and the position of the heat pipe, therefore, the heat pipe can be accurately aligned with the radiating fins, and the situation that the heat pipe andthe radiating fins are crushed due to misplaced assembly of the heat pipe can be avoided.

Owner:GUANGDONG POWER GRID CO LTD +1

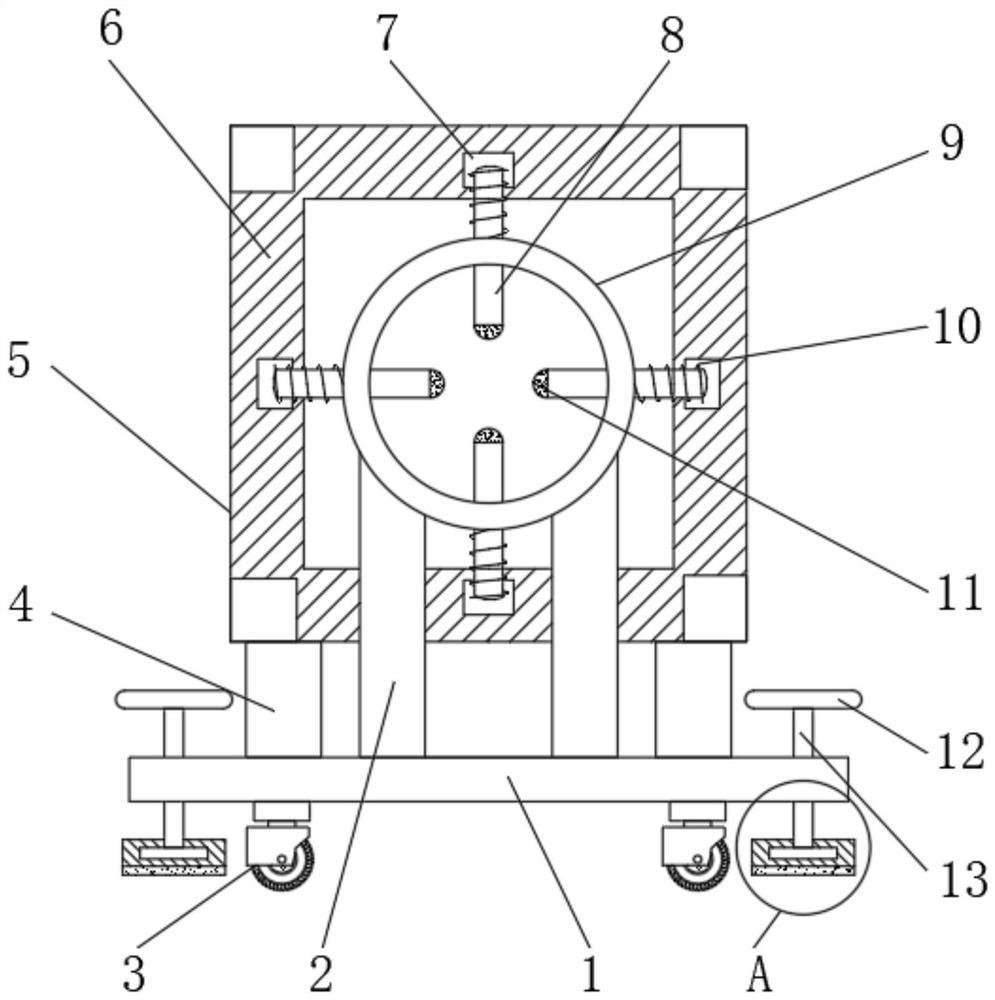

A kind of slewing crane around the pile

The invention discloses a pile-around revolving crane and belongs to the field of cranes. The pile-around revolving crane comprises a lifting mechanism, a revolving platform and a base. The revolving platform is arranged at the upper end of the base, the lifting mechanism is arranged on the revolving platform, the base comprises a fixed base, a cylindrical supporting column and a revolving supporting ring, one end of the cylindrical supporting column is connected to the fixed base, and the other end of the cylindrical supporting column is connected to the revolving supporting ring. The revolving platform comprises a rotary table, a forward roller assembly and a backward roller assembly. The forward roller assembly is arranged on the rotary table, and the backward roller assembly is arranged on the rotary table through a backward roller supporting base. The forward roller assembly and the backward roller assembly each comprise a roller support and a roller, wherein the roller support is rotationally connected to the rotary table or the backward roller supporting base, and the roller rolls on the upper and lower surfaces of the revolving supporting ring along with rotation of the revolving platform. Due to the fact that the revolving plane of each roller support is parallel to the revolving axis of the revolving platform, when the surface of the revolving supporting ring is not flat, the roller supports will revolve to enable the rollers to press the revolving supporting ring.

Owner:WUHAN MARINE MACHINERY PLANT

Input module of fire-fighting linkage control system and using method

PendingCN111312543APrevent fallingAvoid crushed situationsElectric switchesControl systemEngineering

The embodiment of the invention discloses an input module of a fire-fighting linkage control system and a using method. The input module comprises a switch base and a top cover connected with the switch base, a terminal seat is mounted on the upper surface of the switch base, and wire holders are installed on the two sides of the bottom end of the terminal base. A clamping groove is formed in theside surface of the terminal base, an object clamping mechanism is connected in the clamping groove, the equipment is provided with the object clamping mechanism, when not in use, a blocking cover canplay a role in blocking, impurities are prevented from falling into gaps of the terminals; and meanwhile, when a wire is inserted, a pressing block can be pressed firstly to enable the blocking coverto rotate so as not to block the terminal any more, the wire is inserted then, a rubber movable block is pulled out at the same time, a rubber clamping block is rotated to clamp the wire, then the top cover can be closed, and at the moment, the connection position between the wire and the terminal is lifted, so that the connection position between the wire and the terminal does not form a vertical table, and the situation that the wire is crushed is avoided.

Owner:GUANGDONG POWER GRID CO LTD +1

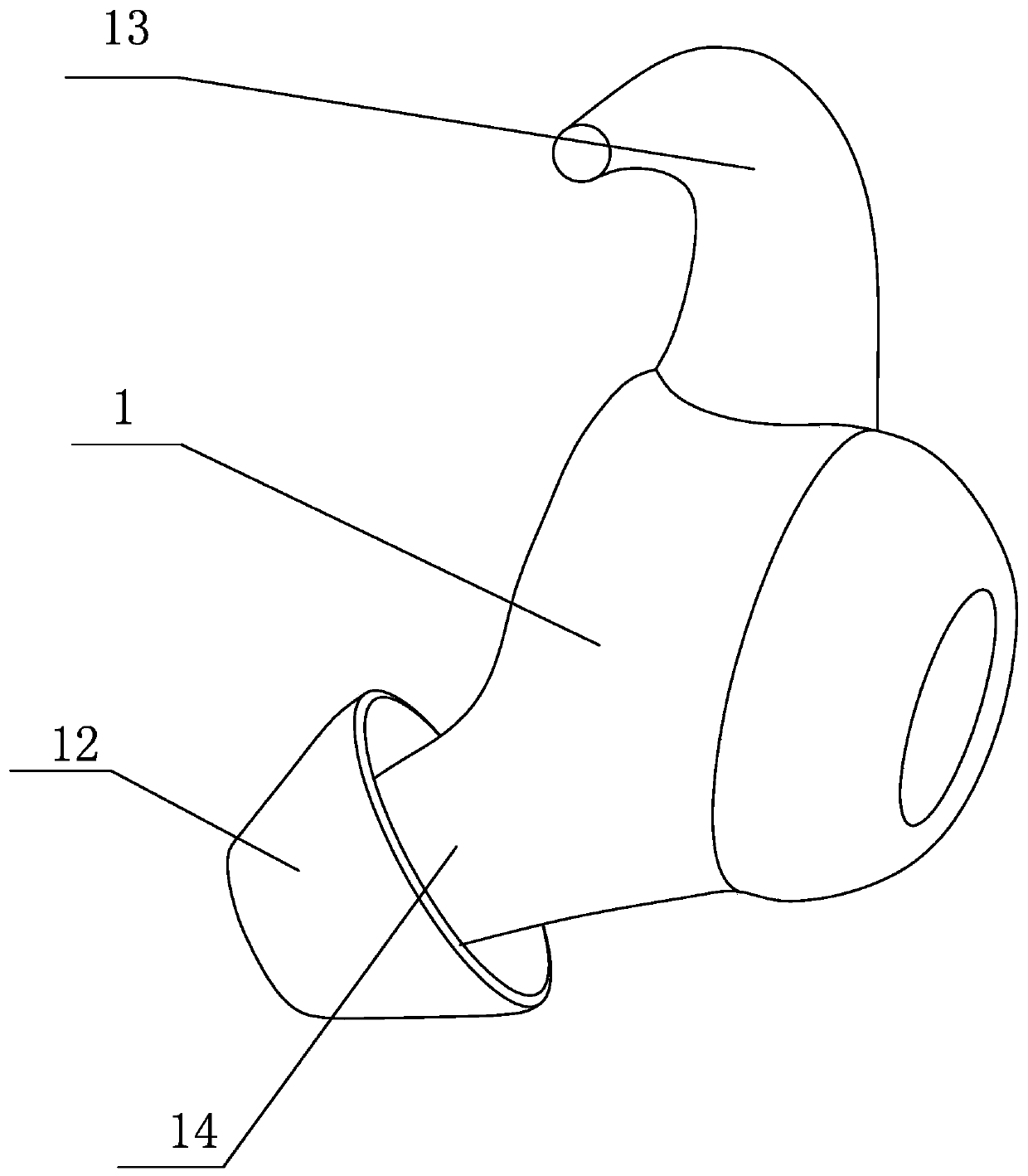

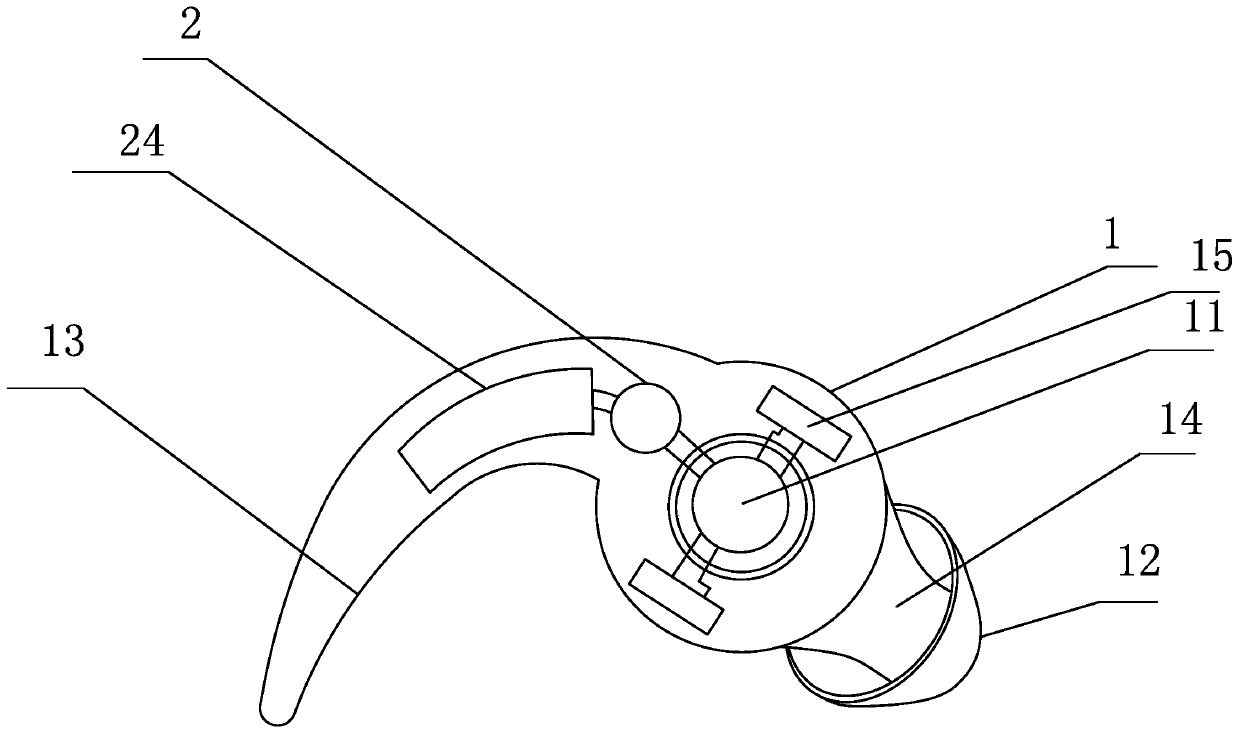

Wireless alarm clock earphone

PendingCN110719541AGuaranteed cleanlinessEasy to fixTime indicationCurrent supply arrangementsExternal Auditory CanalsEar plugging

A wireless alarm clock earphone device comprises a main body used for being placed in the auricular concha cavity. The main body is provided with earplugs used for being plugged into external auditorycanals of ears. A vibration assembly used for generating vibration sense and a receiving chip used for receiving mobile phone information of a user are arranged in the main body, and the receiving chip is in communication connection with the vibration assembly. According to the present invention, the structure is simple, the fixation is stable, the user can be rapidly awakened under the conditionof no influence on the sleep of other people, and the probability that the user is affected by the external noise when the user falls asleep can be reduced with the technology.

Owner:翁源骏

An automatic assembly line for heat pipe radiators

ActiveCN112475062BEasy to operatePrecise alignmentMetal-working feeding devicesHeat exchange apparatusHeat AvoidanceAssembly line

The embodiment of the present invention discloses an automatic assembly production line for heat pipe radiators, which includes a workbench and an unloading conveying mechanism installed at the end of the workbench and used to feed the cooling fins. A fixing frame is installed on the side of the workbench. The fixing frame is equipped with a pipe delivery positioning mechanism for fixing the heat pipe and fixing the heat sink on the side wall of the heat pipe. The present invention can quickly install multiple heat pipes on the stamping equipment through the fixing block, the clamping device and the circulation frame. In order to improve the assembly efficiency of the device, when implementing, only install the heat pipe on the fixed block and fix it through the clamp, and then clamp the fixed block in the circulation frame, and then drive the positioner to make the fixed block and the heat pipe When the heat pipe moves to the top of the assembly seat, the position of the fixed block and the heat pipe can be fixed by driving the positioner, so that the heat pipe can be accurately aligned with the heat sink, which can avoid the misalignment of the heat pipe assembly, resulting in heat pipe and heat dissipation The situation where the sheets are all crushed occurs.

Owner:GUANGDONG POWER GRID CO LTD +1

Fixing device for plastic pipe production

ActiveCN111531626BQuick fixEasy to useMetal working apparatusPositioning apparatusHydraulic cylinderPlastic pipework

The invention discloses a fixing device for plastic pipeline production, which comprises a bottom plate, a movable frame and a fixed cylinder. The top outer wall of the bottom plate is provided with a support column, and the top outer wall of the support column is welded to the bottom outer wall of the fixed cylinder. The bottom plate A fixed plate is welded on the outer wall of the top of the fixed plate, and a hydraulic cylinder is connected to one side of the fixed plate by bolts. One end of the piston of the hydraulic cylinder is connected to the outer wall of one side of the movable frame by bolts. The outer walls around the fixed cylinder are provided with slide holes, and the inner walls of the slide holes are slidably connected with a slide bar, and the outer wall of one end of the slide bar is welded with a slide block, and the section of the slide block is a right-angled trapezoid. The rubber block at the top of the sliding rod in the present invention can hold against the outer wall of the pipe and play a fast fixing role. When the pipe needs to be removed, only need to drive the hydraulic cylinder to work in reverse to make the pipe free from the restriction of the rubber block, which is very convenient to use , effectively speeding up the fixing efficiency of the device.

Owner:山东康雨管业有限公司

A three-dimensional parking device and its control method

The invention provides stereoscopic parking equipment and a control method thereof. The stereoscopic parking equipment comprises a garage frame (1), a left upper-layer car carrying plate (3) and a right upper-layer car carrying plate (8) arranged in the garage frame, a bottom-layer car carrying plate (5) arranged in a left-right transverse movement manner, a motor (4) capable of controlling forward and backward rotation, and a transmission sprocket set driven by the motor (4). The transmission sprocket set comprises driving sprockets (7), left driven sprockets (31) respectively mounted on the left and right sides of the right upper-layer car carrying plate (8), and transmission chains (2) connecting the driving sprockets (7), the left driven sprockets (31) and right driven sprockets (81). Compared with the prior art, the stereoscopic parking equipment has the advantages that lifting of the two upper-layer car carrying plates is realized only through one motor, motor number is reduced, manufacturing cost is saved, the motor is low in overall load, and energy consumption is further reduced. Besides, the control method is simple in step, convenient to operate and quite safe.

Owner:SJEC CORP

A hardware storage box for computer interaction

ActiveCN111232384BEasy accessPlay the role of limiting the position of the hard disk bodyContainers preventing decayContainers to prevent mechanical damageComputer architectureSoftware engineering

The invention discloses a hardware storage box for computer interaction. The top outer wall of the top plate is provided with a top plate, and the top outer wall of the top plate is fixedly connected with a handle, and one side of the outer wall of the storage tube is provided with storage slots distributed equidistantly, and a hard disk body is placed inside the storage slot, and the storage slot A side rod is welded on the inner wall of one side, and a limiting cylinder is arranged on the outer wall of one end of the side rod, the inner wall of the limiting cylinder is slidably connected with a connecting rod, and the shape of the connecting rod is U-shaped, and the bottom outer wall of the connecting rod is provided with The backing plate is welded with a sleeve on the top inner wall of the receiving groove. The invention makes the hard disk body easy to take and avoid damage caused by falling to the ground due to the shaking of the box body. The use effect is better, and the hard disk is more convenient to access, which further improves the use effect of the device.

Owner:光禹莱特数字科技(上海)有限公司

Vehicle pedal device

ActiveCN104325935AReduced service lifeSave spaceSuperstructure subunitsSteps arrangementCar doorEngineering

The invention provides a vehicle pedal device and belongs to the technical field of vehicle fittings. The problem of relatively large occupation space caused when the current welcoming pedal cannot be retracted when not being used is solved. The vehicle pedal device comprises a vehicle body, wherein vehicle doors are connected to two opposite side walls on the vehicle body; grooves are formed in the two side walls, connected with the vehicle doors, of the vehicle body; each groove comprises a planar bottom wall; a pedal and a plurality of guide components which are vertically arranged on the bottom wall are arranged in each groove; the pedals are long bar-shaped and are glidingly connected to the guide components; a driving component enabling the outer end of each pedal to go out of the groove is also arranged in each groove; a sealing plate which can seal each groove is connected with the outer end of each pedal. The vehicle pedal device has the advantage of retracting the pedals.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

car pedal device

ActiveCN104325935BSmall footprintCompact structureSuperstructure subunitsSteps arrangementEngineeringCar door

The invention provides a vehicle pedal device and belongs to the technical field of vehicle fittings. The problem of relatively large occupation space caused when the current welcoming pedal cannot be retracted when not being used is solved. The vehicle pedal device comprises a vehicle body, wherein vehicle doors are connected to two opposite side walls on the vehicle body; grooves are formed in the two side walls, connected with the vehicle doors, of the vehicle body; each groove comprises a planar bottom wall; a pedal and a plurality of guide components which are vertically arranged on the bottom wall are arranged in each groove; the pedals are long bar-shaped and are glidingly connected to the guide components; a driving component enabling the outer end of each pedal to go out of the groove is also arranged in each groove; a sealing plate which can seal each groove is connected with the outer end of each pedal. The vehicle pedal device has the advantage of retracting the pedals.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Locking plate assembling machine for connector

ActiveCN110544859AImplement continuous insertionGuaranteed accuracyContact member assembly/disassemblyEngineeringCam

Owner:DONGGUAN UNIV OF TECH

Tea leaf processing and rolling device

PendingCN114847370AAvoid pouring situationsGuaranteed stabilityPre-extraction tea treatmentButt jointEngineering

The invention discloses a tea leaf processing rolling device, and relates to the technical field of tea leaf processing, the tea leaf processing rolling device comprises a bearing box, and the bottom of the bearing box is fixedly connected with a buffer device. Lifting of the device is limited through a movable block and a connecting rod at the bottom of a second telescopic cylinder, and then the movable block is supported through a first spring, so that the stability of the buffering device during lifting of the device is guaranteed, the situation that tea leaves in the device are scattered due to vibration in the lifting process is avoided, and therefore the using stability of the device is improved; heat is transferred to a conduction plate through a heat exchanger, then the conduction plate is cooled, then tea leaves are poured on the conduction plate, so that the tea leaves can be rapidly cooled, then the tea leaves are rolled through mutual cooperation of a convex block and a rolling plate, and in addition, an insertion rod is in butt joint with a connecting column; and the position of the connecting column is prevented from deviating in the tea leaf processing process, so that the use efficiency of the device is improved.

Owner:朱彦峰

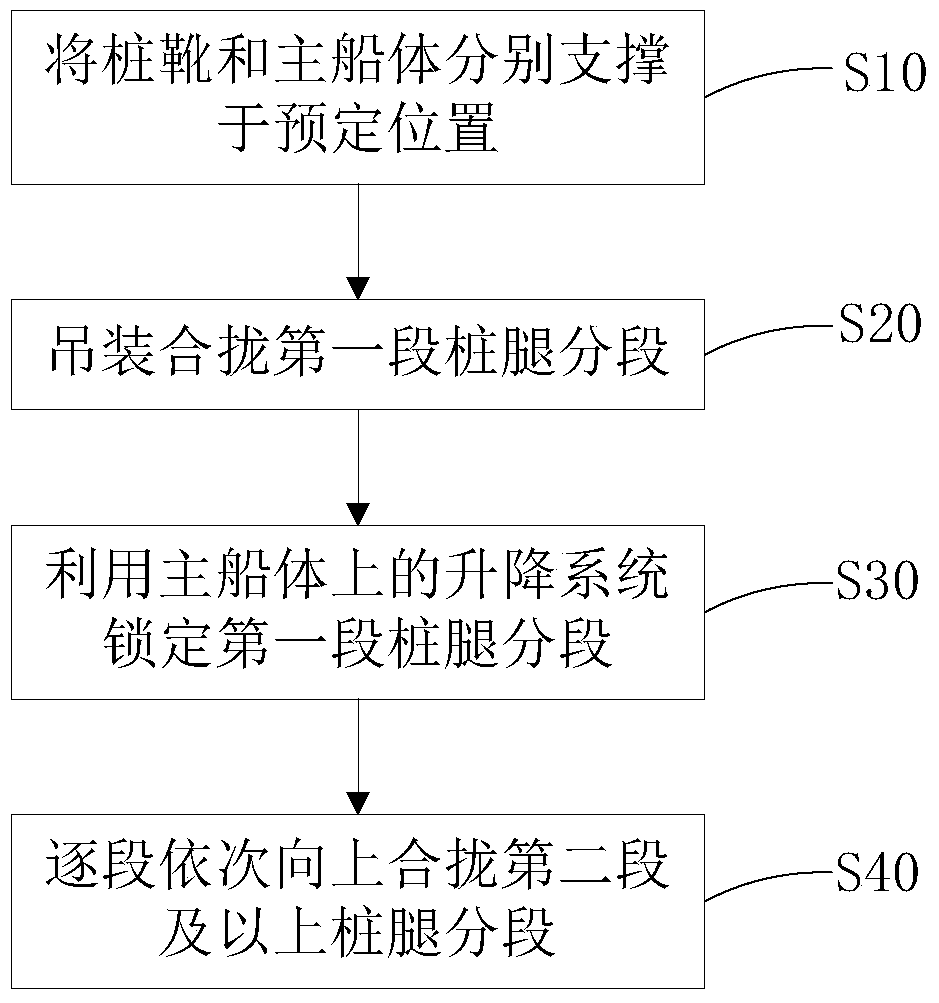

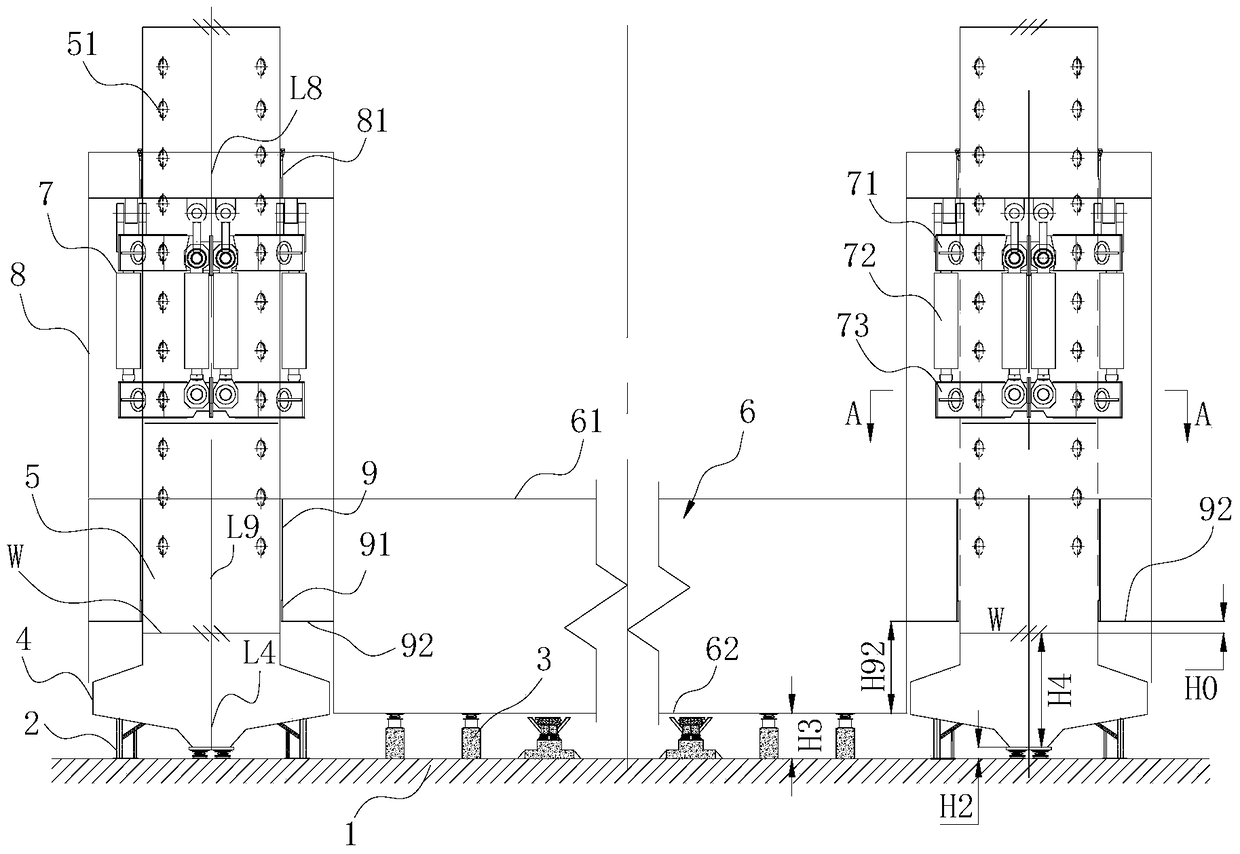

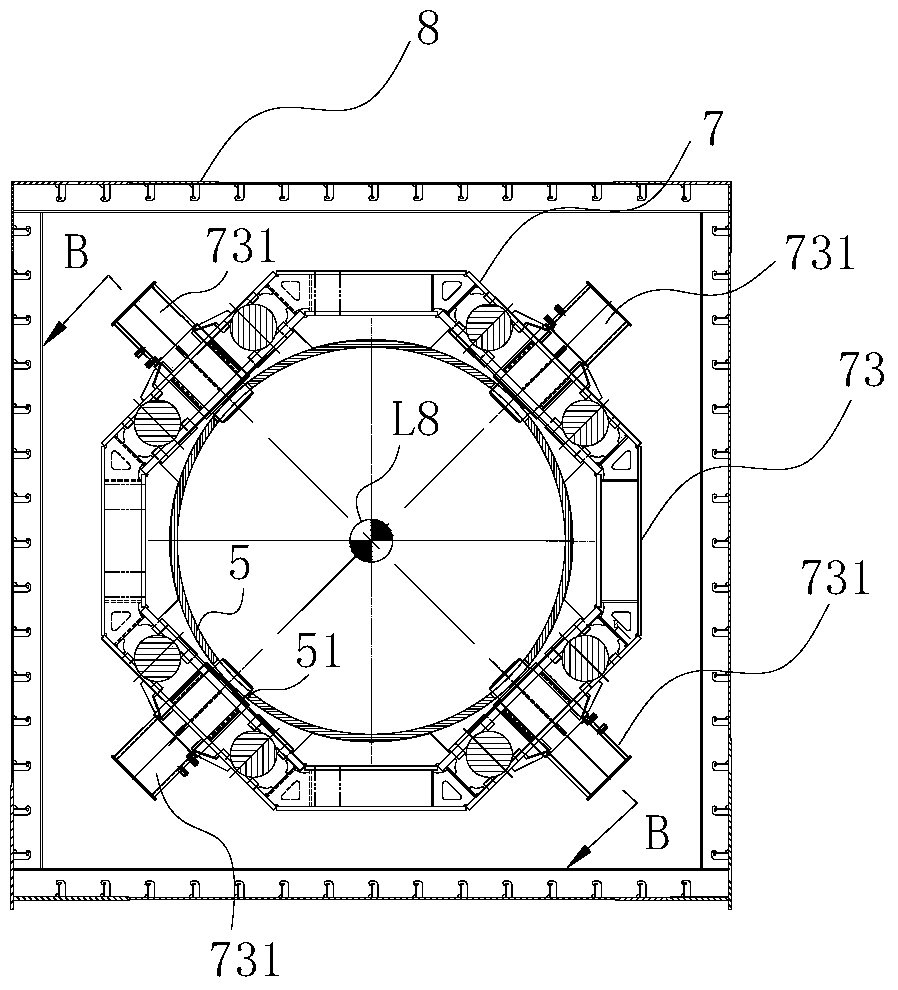

Method for closing legs of hydraulic plug-in self-elevating platform

ActiveCN106351197BReduce difficultyReduce security risksArtificial islandsUnderwater structuresMarine engineeringBody support device

The invention provides a pile leg folding method of a hydraulic bolt type self-lifting platform. The method includes the steps of supporting pile shoes and a ship body at preset positions respectively, wherein the pile shoes are supported and fixed by pile shoe supporting devices, the ship body is supported by a ship body supporting device, and the pile shoes are located under a lifting system on the ship body before being folded together with pile legs; first pile leg sections are hoisted and folded, bottom folding seams of the pile leg sections and the pile shoes are folded and welded, and the pile leg sections penetrate through the lifting system on the ship body and are coaxial with the lifting system; the first pile leg sections are locked by the lifting system of the ship body; the locked state of the lifting system and the first pile leg sections is kept, and second pile leg sections, third pile leg sections...and nth pile leg sections are sequentially upward folded section by section. The folded first pile leg sections are locked on the ship body through the lifting system, the weight borne by the pile shoe supporting devices can be shared on the ship body supporting device, safety risks are reduced, folding precision is improved, and operation safety is ensured.

Owner:YANTAI RAFFLES SHIPYARD +2

The management method of the peak period for picking up cars in the two-story lift-and-transverse three-dimensional garage

ActiveCN107256403BEasy to knowImprove pick-up efficiencyDetection of traffic movementIndication of parksing free spacesParking spaceComputer science

Owner:SHANGHAI CHANGYUE AUTOMATION MACHINERY

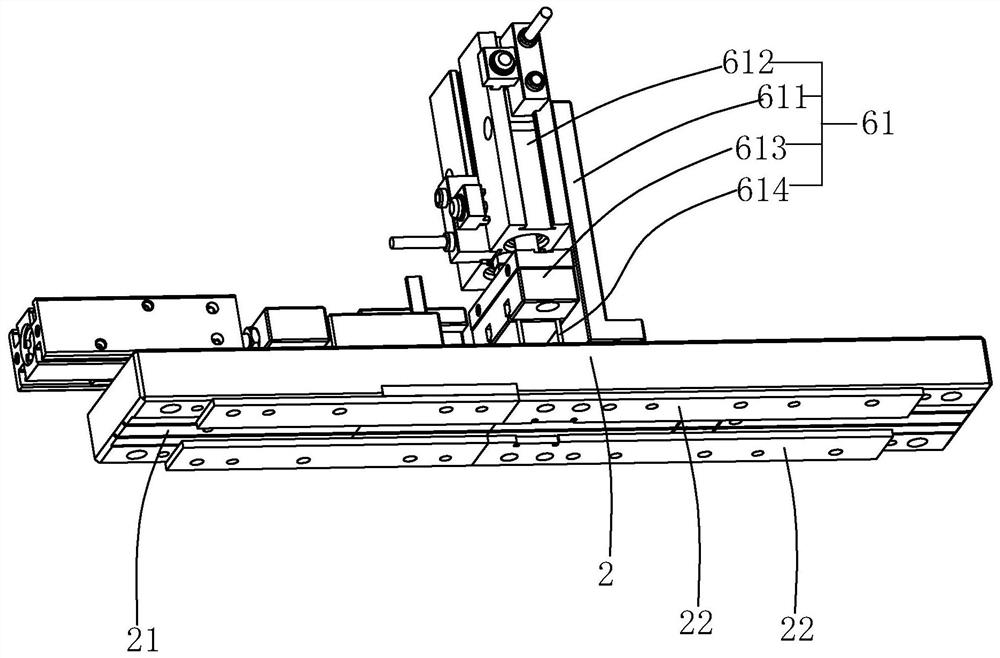

A connector terminal bending insertion machine

ActiveCN107978954BContinuous automatic bend insertionEasy to insertContact member manufacturingContact member assembly/disassemblyEngineeringMechanical engineering

The invention relates to a terminal bending and inserting machine for a connector. The terminal bending and inserting machine for the connector comprises a rack, a terminal conveying device and a terminal bending mechanism; wherein the terminal bending mechanism comprises a terminal bending conveying device and a terminal bending device; the terminal bending device comprises a bending propping material cylinder; the bending propping material cylinder is connected with a bending propping material block; the other side of the carrying terminal is fitted with a bending block, and the bending block is arranged on a bending rotating seat; the bending rotating seat is cooperated with a bending rotating motor; the bending rotating motor and the bending rotating wheel are arranged on a bending movable seat; and the bending movable seat is connected with a bending movable cylinder. According to the terminal bending mechanism of the terminal bending and inserting machine for the connector, the bending of the terminal is realized by the cooperation of the bending propping material block and the rotatable bending block, and the bending block is also provided with a bending inserting plate matched with the groove of the terminal, therefore, good inserting and bending effects can be realized cooperated with rotation, the continuous and automatic bending and inserting of the connector terminals can be realized, the processing efficiency is improved, and the accuracy of bending is ensured.

Owner:SAIYANG ELECTROMECHANICAL

a packing box

ActiveCN108820556BReduce breakageDoes not affect recyclingContainers to prevent mechanical damageEngineeringAirbag deployment

The invention relates to the technical field of protective package, and particularly discloses a packaging box with a protection function in the transporting process. The packaging box comprises a packaging box body and a protection air bag, the protection air bag is arrange don the inner side wall of the packaging box body in a surrounding manner, an air leakage hole is formed in the protection air bag, an air supply device for supplying air for the protection air bag is arranged on the inner side wall of the packaging box body and comprises a cylinder and a piston which are slidably connected, a brake handle is fixedly connected at one end, close to outer side wall of the packaging box body, of the piston, a reset spring is arranged between one end, far away from the brake handle, of thepiston and the cylinder, an air outlet and an air intake are formed in one side of the cylinder with the reset spring and positioned on one side, far away from a handle, of the piston, an air outletone-way valve is arranged on the air outlet, an air intake one-way valve is arranged on the air intake, an air inlet is formed in the protection air bag and communicated with the air outlet. By the aid of the packaging box, clay figurines can be clamped to prevent collision in the transportation process, and the ventilation conditions of the peripheries of the clay figurines can further be improved.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

Ear handle injection molding module

The invention discloses an ear handle injection molding module, which comprises an injection molding bottom mold, an injection molding lower mold and an injection molding upper mold. The first avoidance line groove is connected; the injection molding lower mold is provided with a line-holding half groove and a second avoidance line groove, and the line-accommodating half groove is connected with the second avoidance line groove; the injection molding upper mold is provided with a second ear handle molding cavity and The third avoidance line groove, the second lug molding cavity communicates with the third avoidance line groove; the injection lower mold is used to cover the injection bottom mold, so that the first ear handle forming cavity communicates with the line half groove; The injection molding upper mold is used to cover the injection molding bottom mold, so that the first lug molding cavity communicates with the second lug molding cavity. The invention can save an injection mold and reduce the cost of injection molding. It can also avoid the situation that there is no complete injection molding, so that the quality of the earphone wire can be improved, and the production efficiency of the ear handle injection molding can be further improved.

Owner:雅刚电子(惠州)有限公司

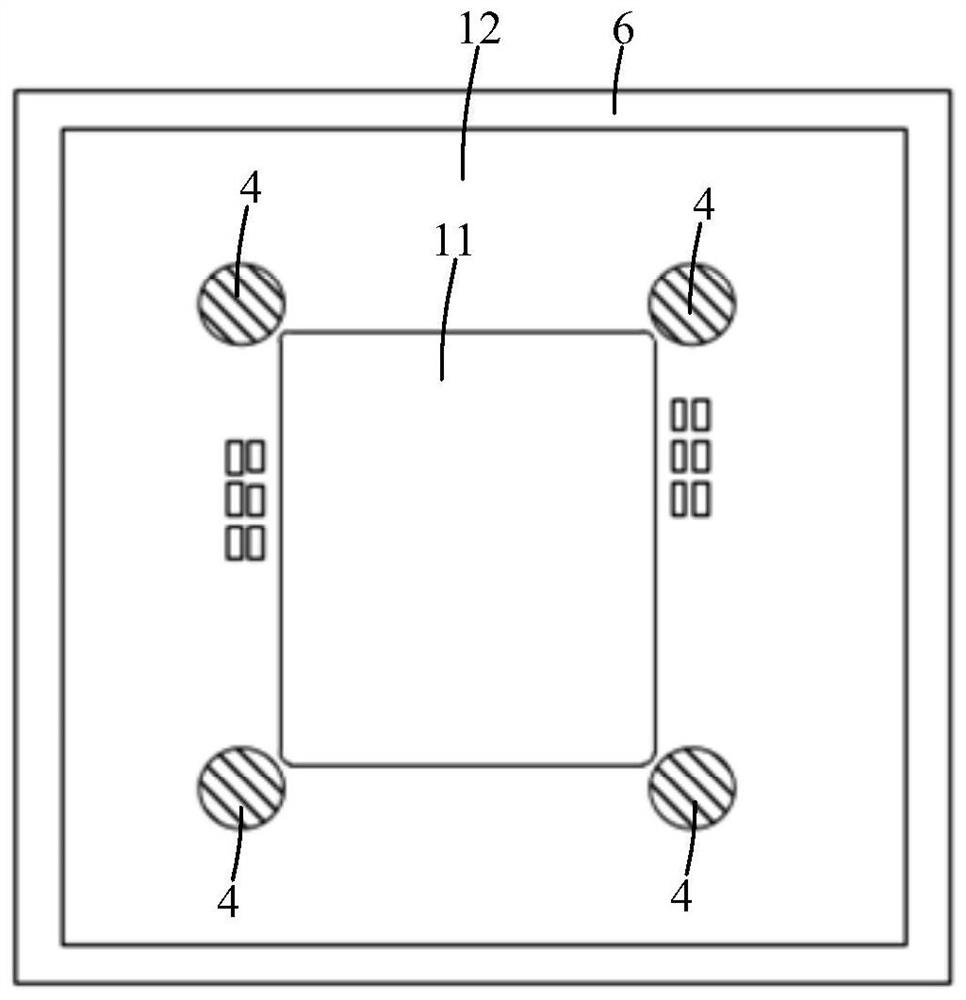

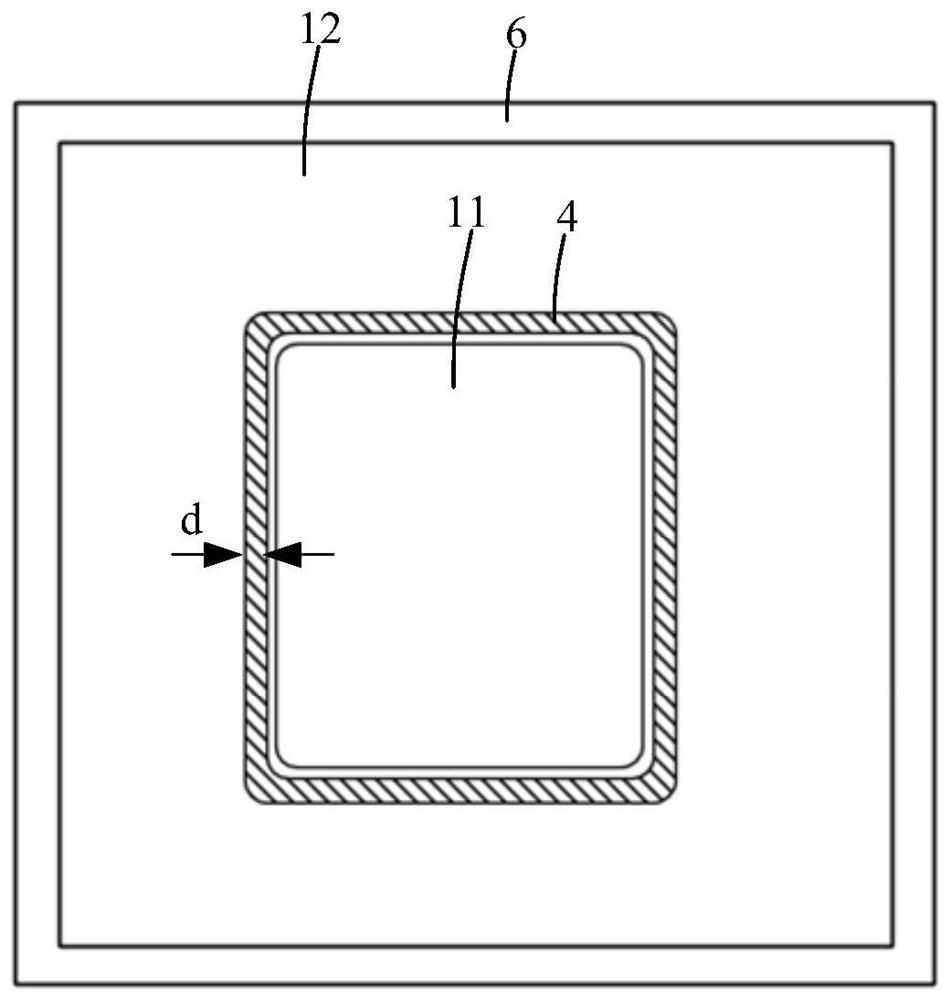

Single board, computing device and manufacturing method

PendingCN113905515ARelieve pressureAvoid crushed situationsPrinted circuit assemblingSemiconductor/solid-state device detailsMonoboardEmbedded system

The embodiment of the invention discloses a single board, computing equipment and a manufacturing method, and belongs to the technical field of chips. The single board comprises a chip, a radiator and a circuit board; the chip comprises a chip device and a chip substrate; the chip device is located on the chip substrate, the chip substrate is located on the circuit board, and the radiator is located on the chip device; a supporting piece is arranged between the chip substrate and the radiator and located on the periphery of the chip device, the first end of the supporting piece is attached to the radiator, and the second end of the supporting piece is attached to the chip substrate. By adopting the scheme of the embodiment of the invention, most or even all of the weight of the radiator is pressed on the supporting piece, so that a higher pressure applied to the chip device by the radiator can be reduced or even avoided, the chip device is protected, and the condition that the chip device is crushed by the radiator can be avoided.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com