Tea leaf processing and rolling device

A rolling device and tea technology, which is applied in tea processing before extraction, etc., can solve the problems of time consumption, waste of resources, failure to roll tea leaves, etc., and achieve the effect of improving stability, ensuring stability, and avoiding tea spilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

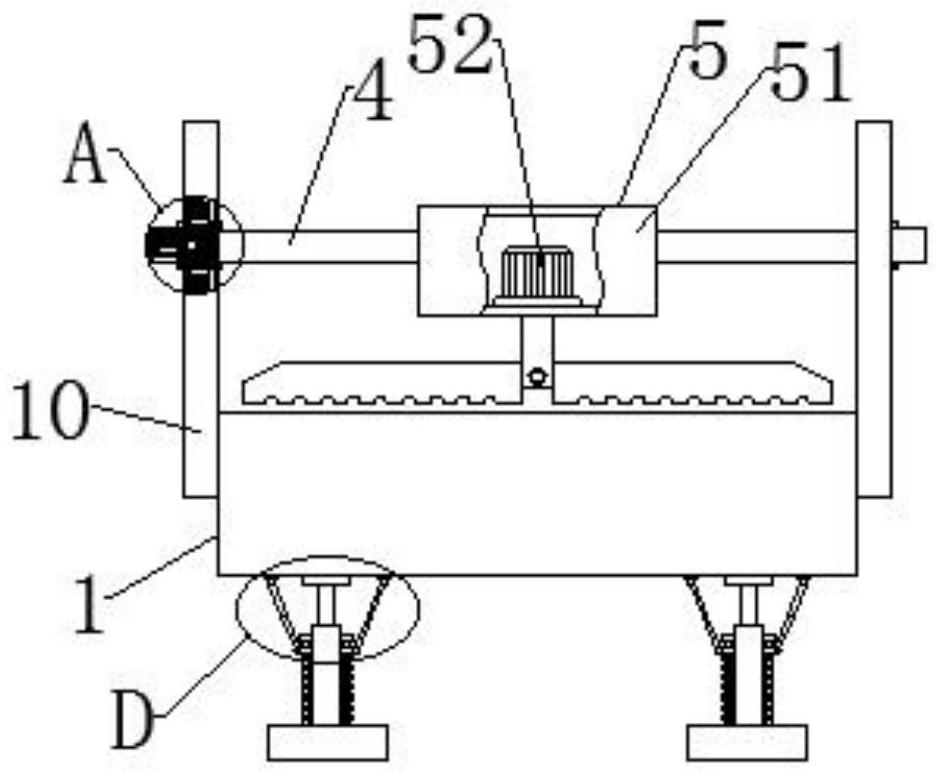

[0039] like Figure 1-8 As shown, it includes a carrying box 1, the bottom of the carrying box 1 is fixedly connected with a buffer device 2, the left side of the carrying box 1 is provided with a lifting device 3, the right side of the lifting device 3 is fixedly connected with a connecting bracket 4, and the right end of the connecting bracket 4 A drive device 5 is fixedly connected, the bottom of the drive device 5 is provided with a kneading device 6, the bottom left end of the kneading device 6 is provided with an auxiliary device 7, the inside of the carrying box 1 is provided with a temperature control device 8, and the left side of the temperature control device 8 is provided with There is a pressure sensing device 9 .

[0040] Preferably, the buffer device 2 includes a connecting rod 24, the outer wall of the connecting rod 24 is movably connected with a movable block 25, the bottom of the movable block 25 is fixedly connected with a spring 1 26, and the left side of ...

Embodiment 2

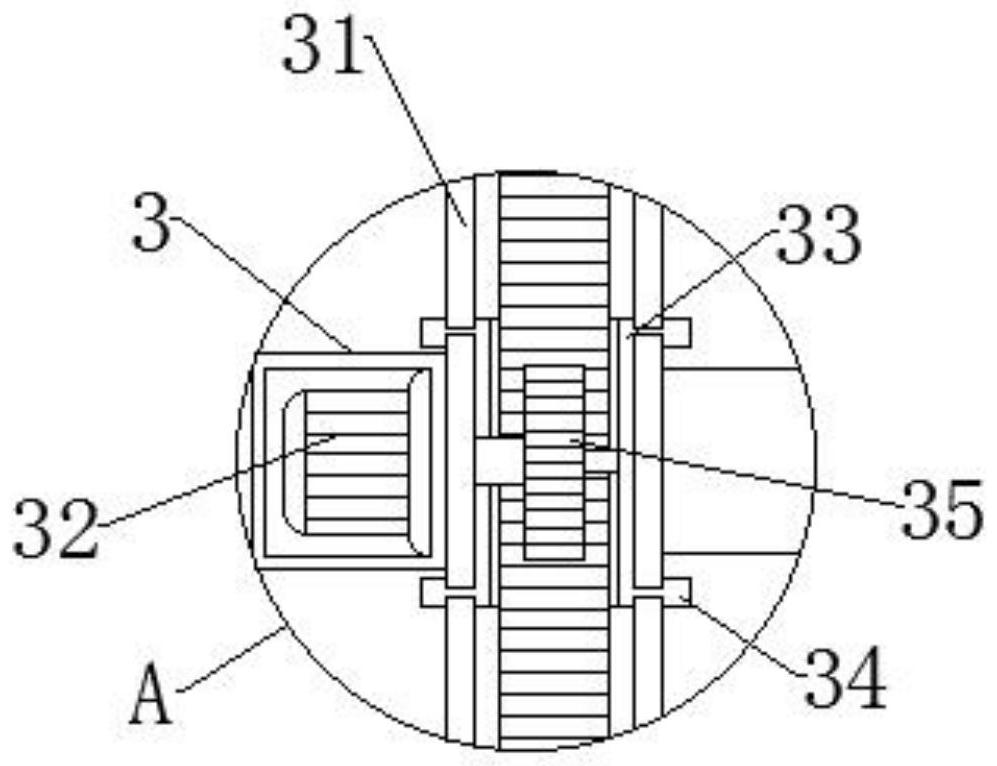

[0044] like Figure 1-8 As shown, the lifting device 3 includes a lifting rail 31, the left side of the lifting rail 31 is fixedly connected with a driving motor 1 32, the inner wall of the lifting rail 31 is movably connected with a lifting block 33, and the right side of the lifting block 33 is fixedly connected with a limit block 34 , a gear 35 is fixedly connected to the output shaft of the driving motor one 32 .

[0045] Preferably, the driving device 5 includes an outer protective shell 51, the inner wall of the outer protective shell 51 is fixedly connected with the second driving motor 52, the output shaft of the second driving motor 52 is fixedly connected with a connecting column 53, and the bottom of the connecting column 53 is provided with a mounting hole. One 54. Mounting hole two 55, the inside of the connecting column 53 is provided with a fixing bolt 56, the kneading device 6 includes a kneading bracket 61, the right side of the kneading bracket 61 is fixedly ...

Embodiment 3

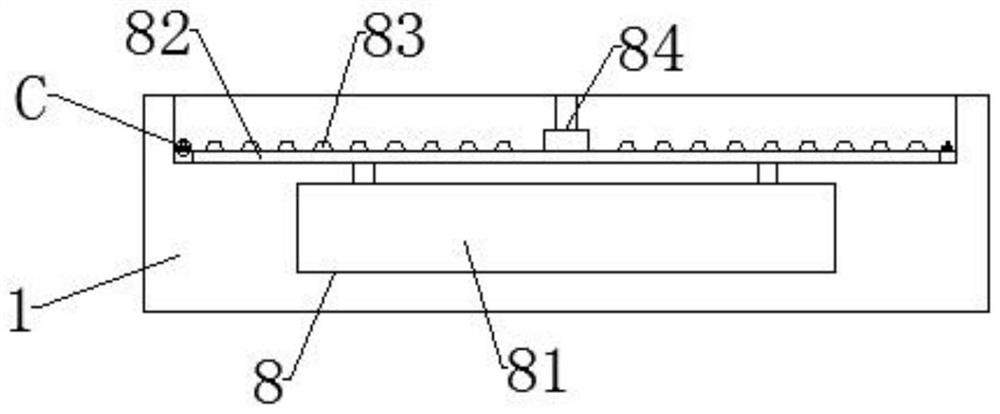

[0049] like Figure 1-8 As shown, an insertion rod 84 is fixedly connected to the middle of the top of the conductive plate 82 , and a protrusion 83 is fixedly connected to the top of the conductive plate 82 around the periphery of the insertion rod 84 .

[0050] Further, the heat is transferred to the conduction plate 82 through the heat exchanger 81, and then the conduction plate 82 is cooled, and then the tea leaves are poured on the conduction plate 82, so that the tea leaves can be rapidly cooled, and then pass through the bumps 83 and kneading. The plates 64 cooperate with each other to knead the tea leaves, and the insertion rods 84 are connected to the connecting posts 53 to prevent the device from offsetting the position of the connecting posts 53 in the tea processing process, thereby improving the efficiency of the use of the device, but some tea leaves It is necessary to knead while the tea leaves are in a warm device, such as oolong tea. The shape of oolong tea re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com