Smelting furnace with harmful gas treatment structure and used for clean production

A harmful gas, clean production technology, applied in the field of furnaces, can solve the problems of fixed collection barrels, high risk, high temperature metal solution pouring, etc., to prevent shaking or tilting, block heat transfer, and avoid pouring effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

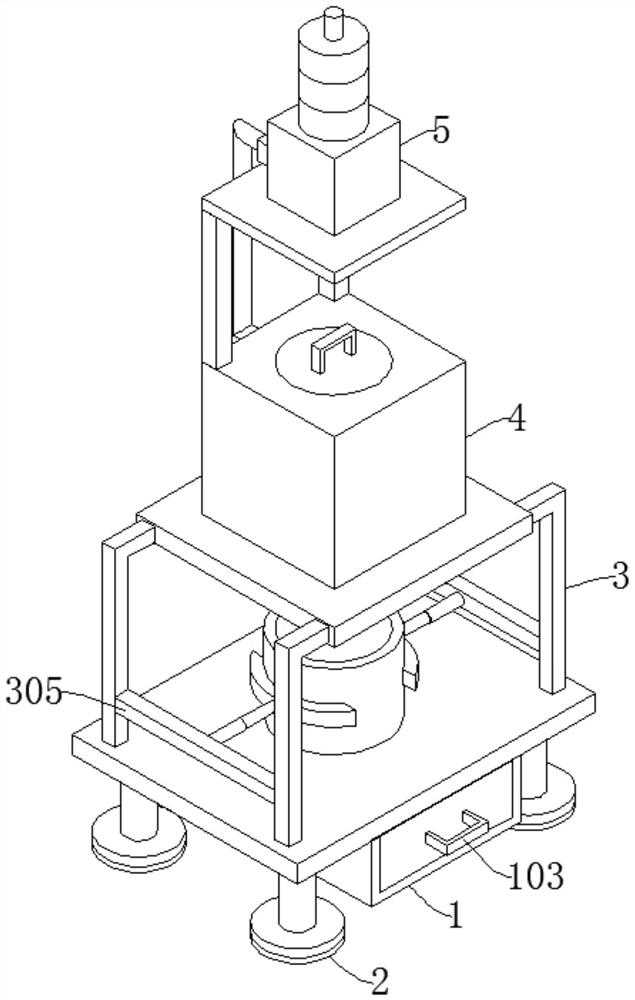

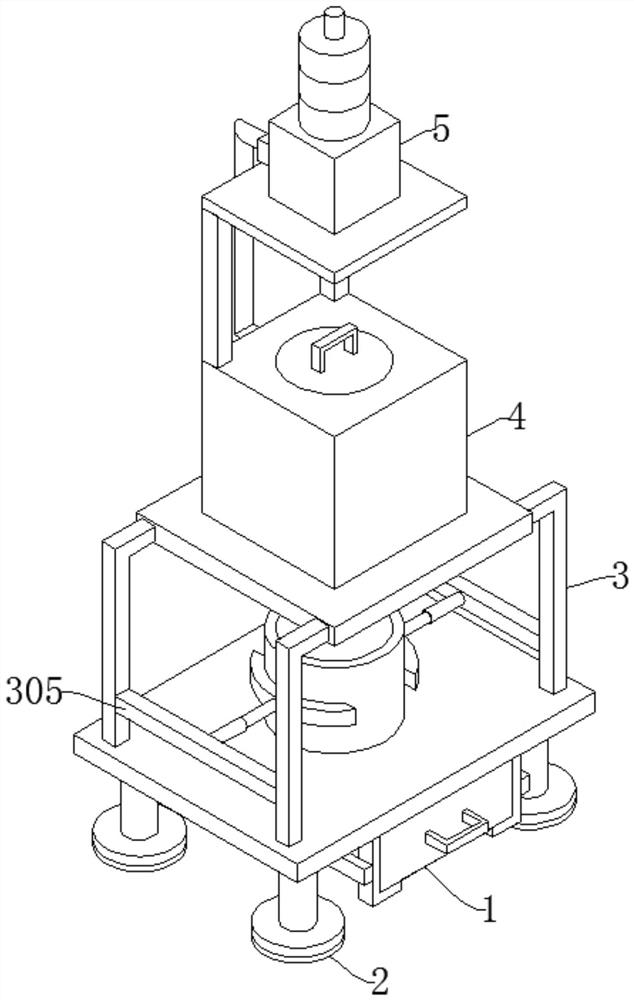

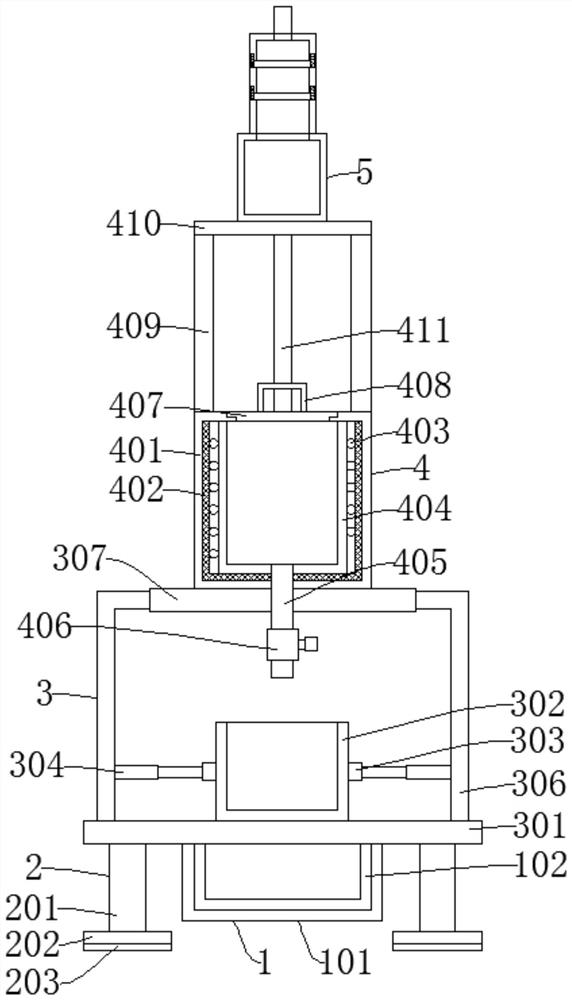

[0042] Such as figure 1 , image 3 , Figure 5 , Figure 7 , Figure 9As shown, a furnace with a harmful gas treatment structure for clean production includes a storage mechanism 1 and a support mechanism 2 for storing items. The support mechanism 2 is arranged on both sides of the storage mechanism 1, and also includes a collection mechanism 3, a heating Mechanism 4 and purification mechanism 5, the collection mechanism 3 is installed above the storage mechanism 1, the heating mechanism 4 is installed above the collection mechanism 3, and the purification mechanism 5 is fixed above the heating mechanism 4;

[0043] The collection mechanism 3 comprises a horizontal plate 301, a collection bucket 302, an arc clip 303, an electric push rod 304, a connecting rod 305, a second L-shaped rod 306, and a fixed plate 307. A collection bucket 302 is arranged above the horizontal plate 301, and a collection bucket 302 Both sides are provided with arc clip 303, and the side of arc cli...

Embodiment 2

[0049] Such as figure 2 , Figure 4 , Figure 6 , Figure 8 , Figure 9 As shown, the difference between Embodiment 2 and Embodiment 1 is that the limit frame 1011 and the baffle 1012 are replaced by the first L-shaped bar 1013 and the U-shaped bar 1014, and the storage is opened through the first handle 103 when relevant tools are needed. The box 102 is sufficient, and the first L-shaped bar 1013 and the U-shaped bar 1014 work together to limit and fix the storage box 102 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com