Protective cap loading device for automatic injection needle assembling system

A technology of automatic assembly and automatic assembly machine, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., and can solve problems such as the inability to automatically press protective caps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

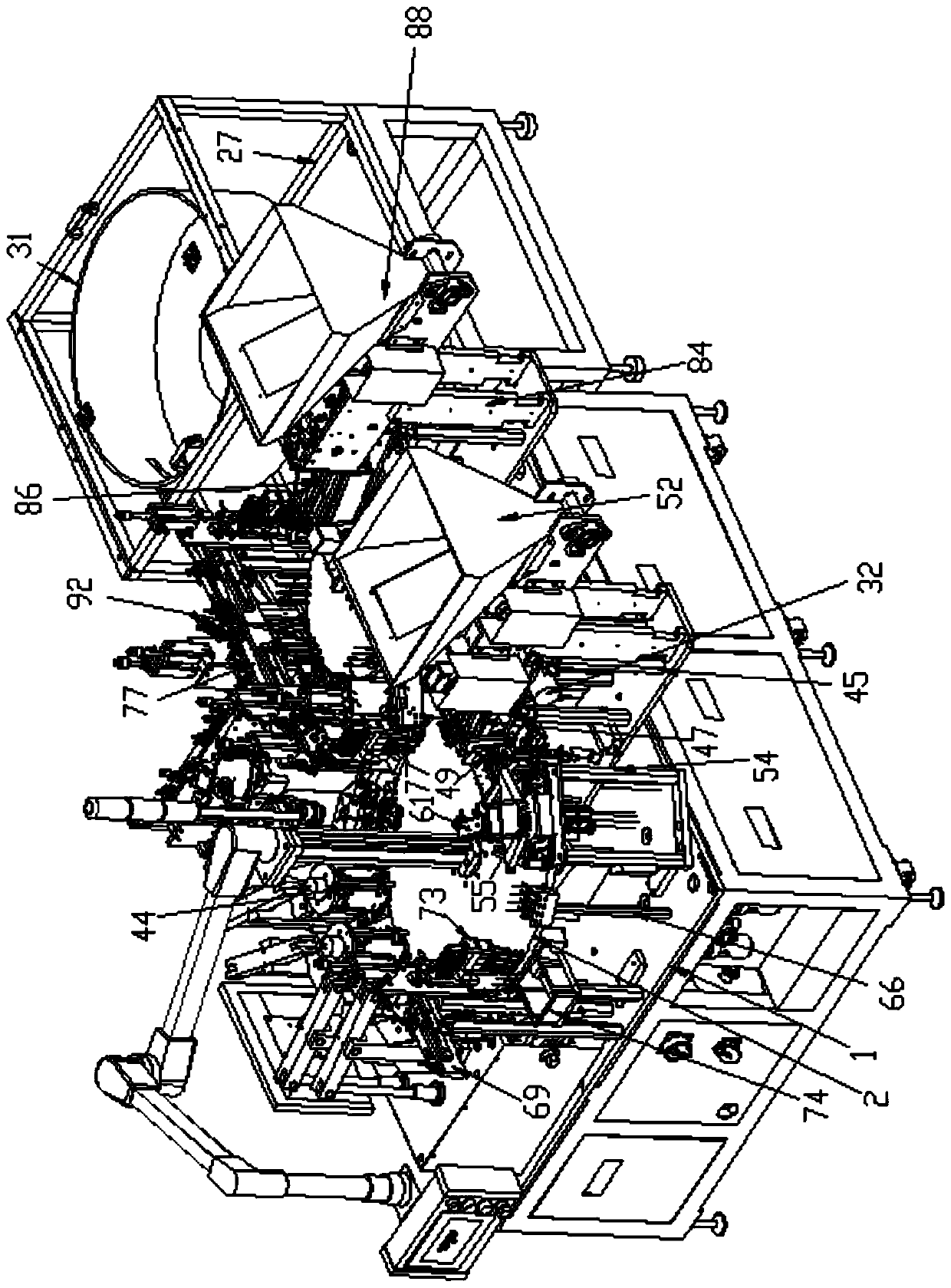

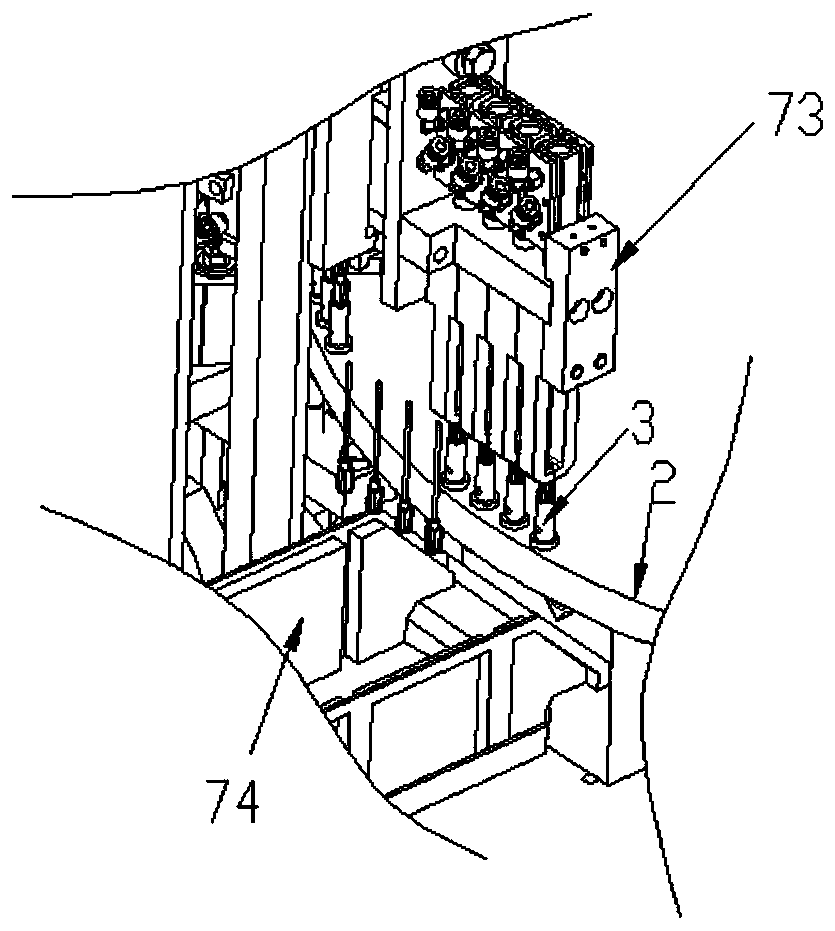

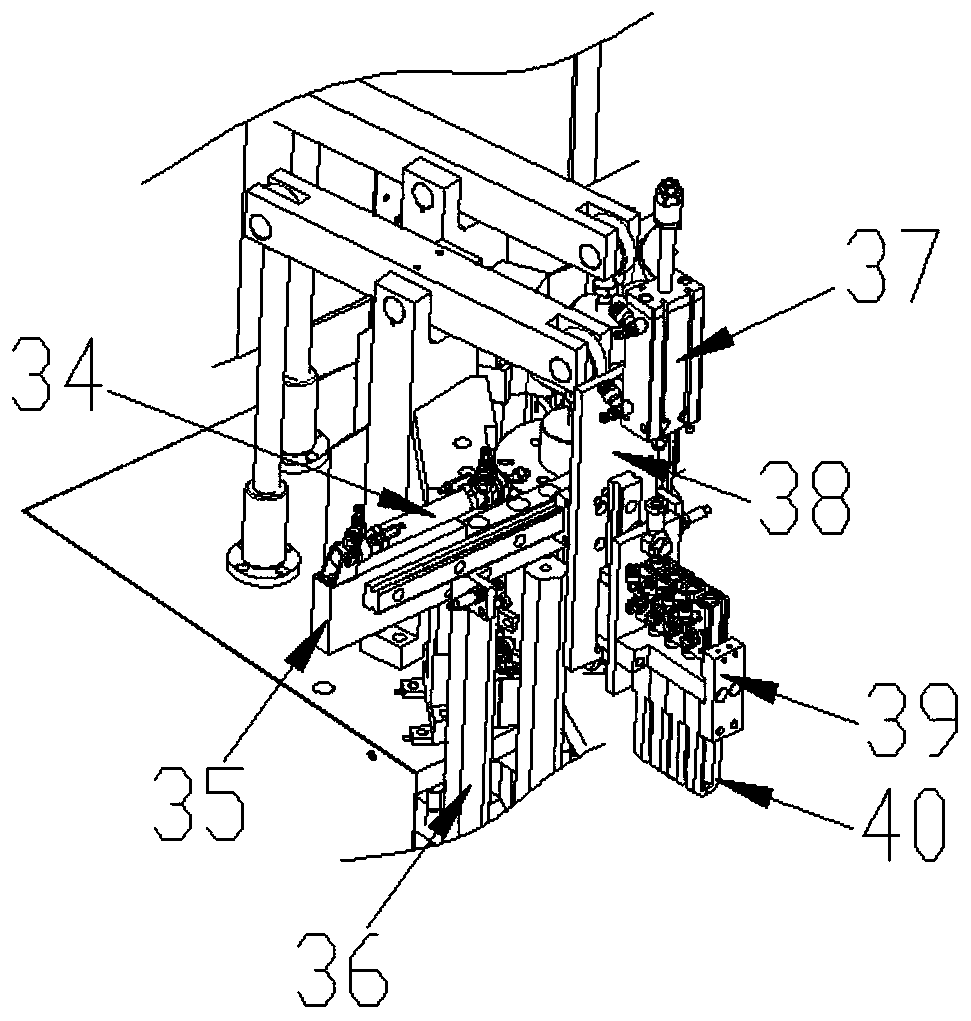

[0015] Such as Figure 1 to Figure 36 shown (for ease of illustration, Figure 15 Only one line is used to represent the conveying track of the spiral cap and the gap and protrusion on the spiral slide rail are not shown), the present invention is an automatic injection needle assembly machine and a process for assembling injection needles using it, including needle loading equipment 1. Sheath upper equipment and cap upper equipment; the needle upper equipment includes a first turntable 2 that is rotatably connected to the injection needle automatic assembly machine table 1, and a circular array on the first turntable 2 is fixedly provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com