a packing box

A packaging box and airbag technology, applied in the direction of transportation and packaging, containers, containers to prevent mechanical damage, etc., can solve the problems of wasting materials, limited cushioning effect, poor ventilation effect, etc., to improve ventilation, save energy, and benefit The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

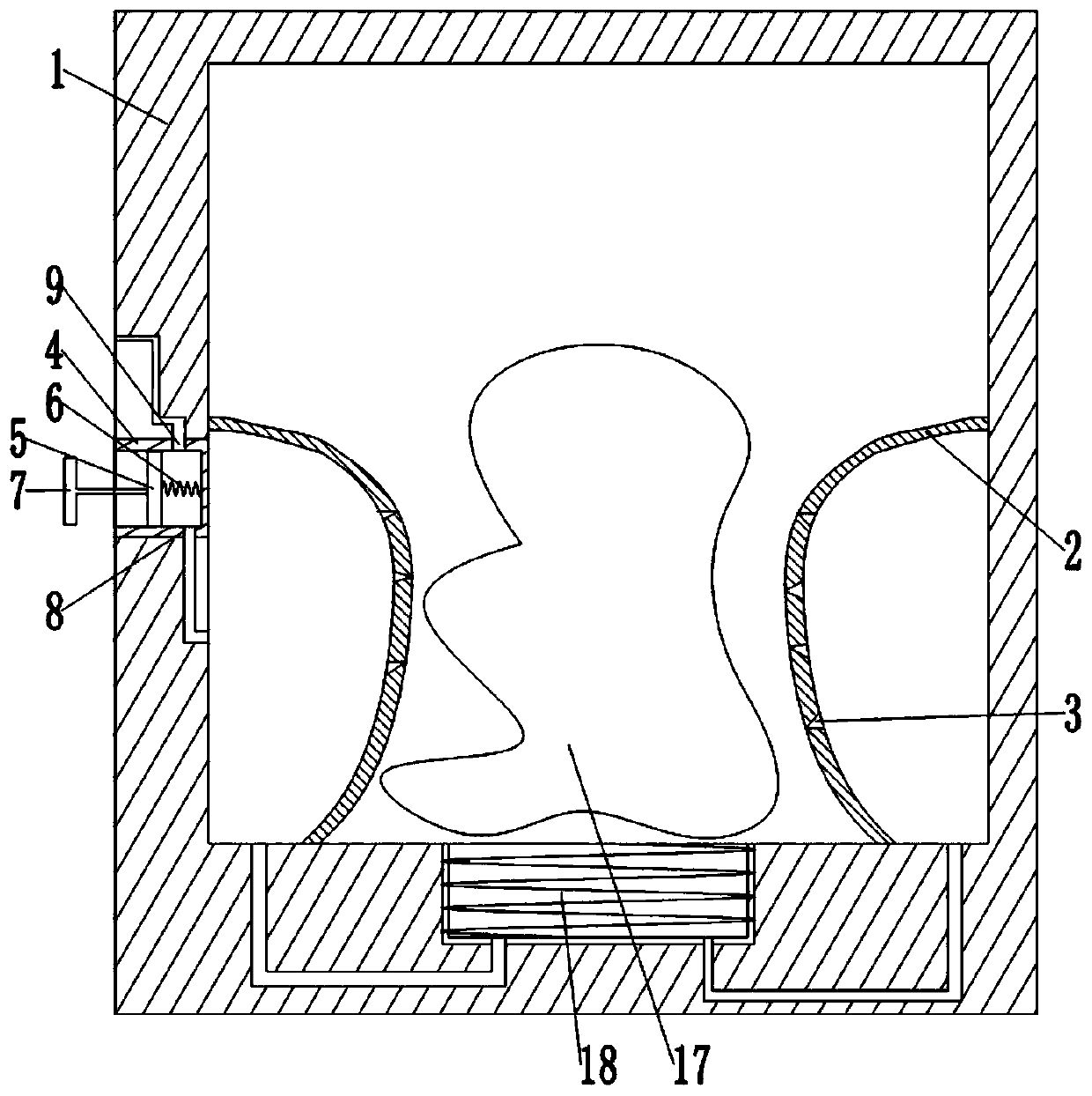

[0028] Basic as attached figure 1 As shown, a packing box includes a packing box body 1 , a protective airbag 2 and an air supply device for inflating the protective airbag 2 .

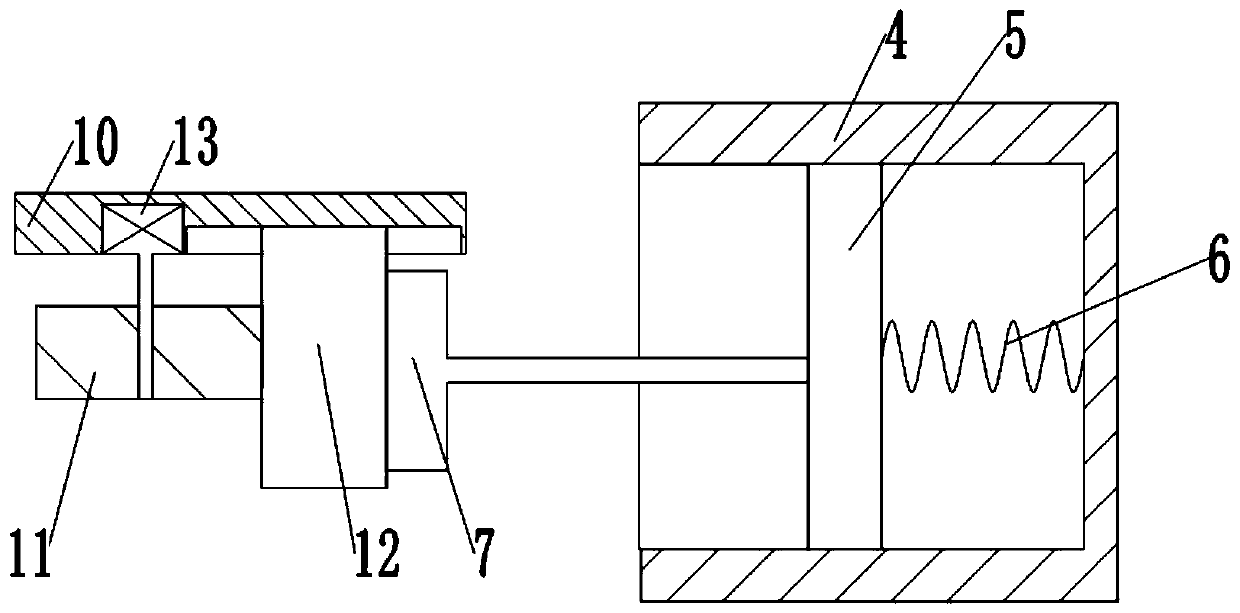

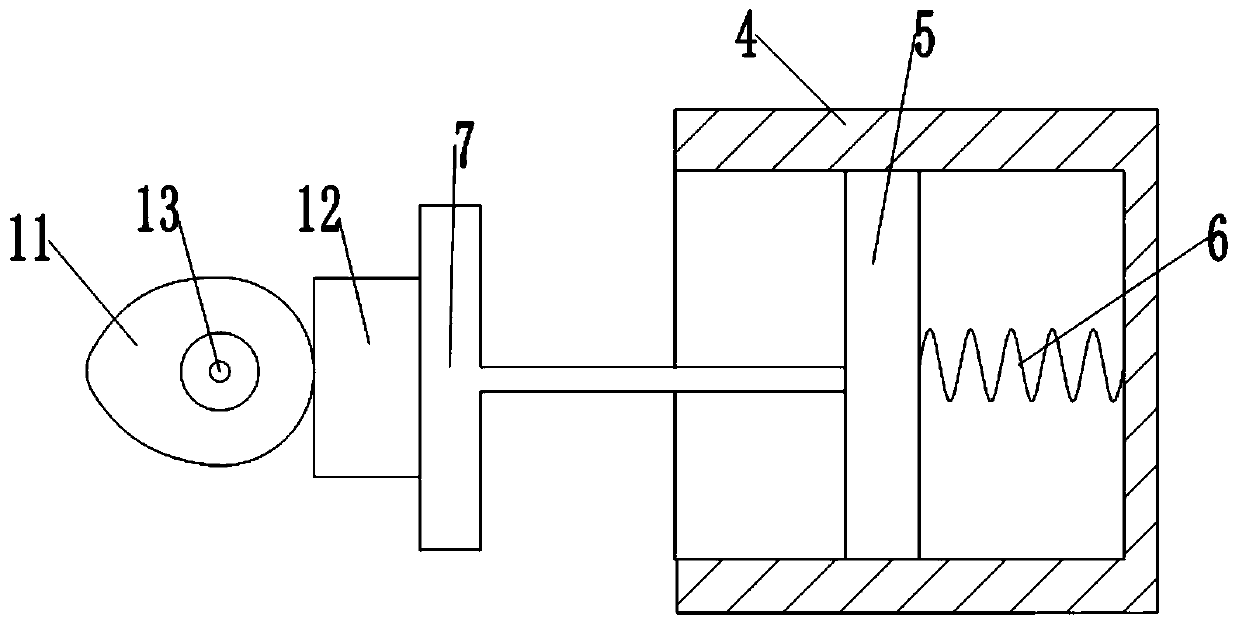

[0029] The protective airbag 2 is fixedly arranged on the inner surfaces of the four side walls of the packaging box body 1 , and the protective airbag 2 is integrally formed with a vent hole 3 . In this program, the vent hole 3 is a shrinkable tapered hole, and the end of the tapered hole close to the clay sculpture 17 is a smaller diameter end. The vent hole 3 is provided with a one-way valve. The specific settings are as follows. A layer of latex layer is fixedly connected, and an exhaust hole is integrally formed on the latex layer. When not being subject to a certain intensity of air pressure, due to the characteristics of the latex layer itself, the vent hole is in a closed state; at the initial stage of inflating the protective airbag 2, the latex layer will not be elastically stretched rapidl...

Embodiment 2

[0037] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the vent hole 3 is a plurality of through holes arranged on the protective airbag 2, and a valve plate control rod 14 is slidably connected in each through hole, and the valve plate control rod 14 Stretch out of the protective airbag 2 through the through hole, the right end of the valve plate control rod 14 is a smooth arc and is fixedly connected with a sponge block, and is fixedly connected with the valve plate control rod 14 and the through hole for making the valve plate control rod 14 Return spring 15, the left end of valve plate control rod 14 is fixedly connected with normally closed valve plate 16, and the position around the vent hole 3 on the outer surface of protective airbag 2 is evenly fixedly connected with protrusions. When the right end of the valve plate 16 control plate arrives on the clay sculpture 17, if the air bag 2 continues to be inflated, the air bag 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com