Single board, computing device and manufacturing method

A manufacturing method and veneer technology, which can be used in semiconductor/solid-state device manufacturing, cooling/ventilation/heating transformation, printed circuits connected with non-printed electrical components, etc., and can solve problems such as chip device crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

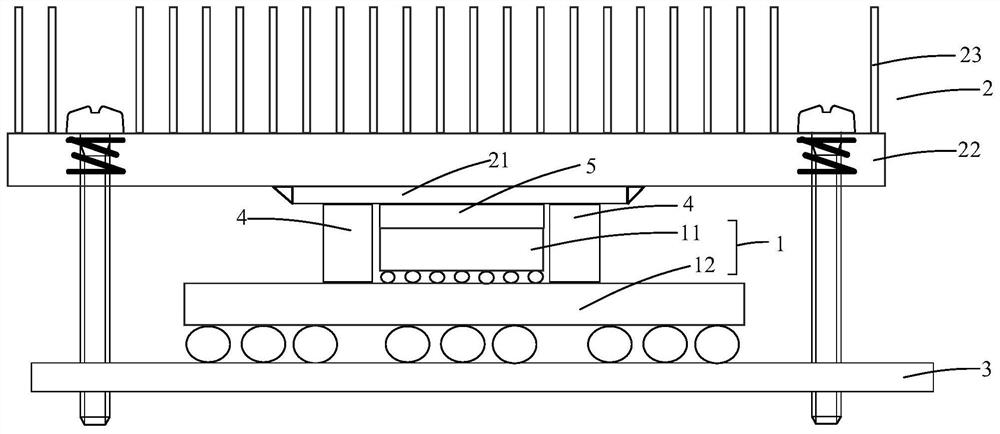

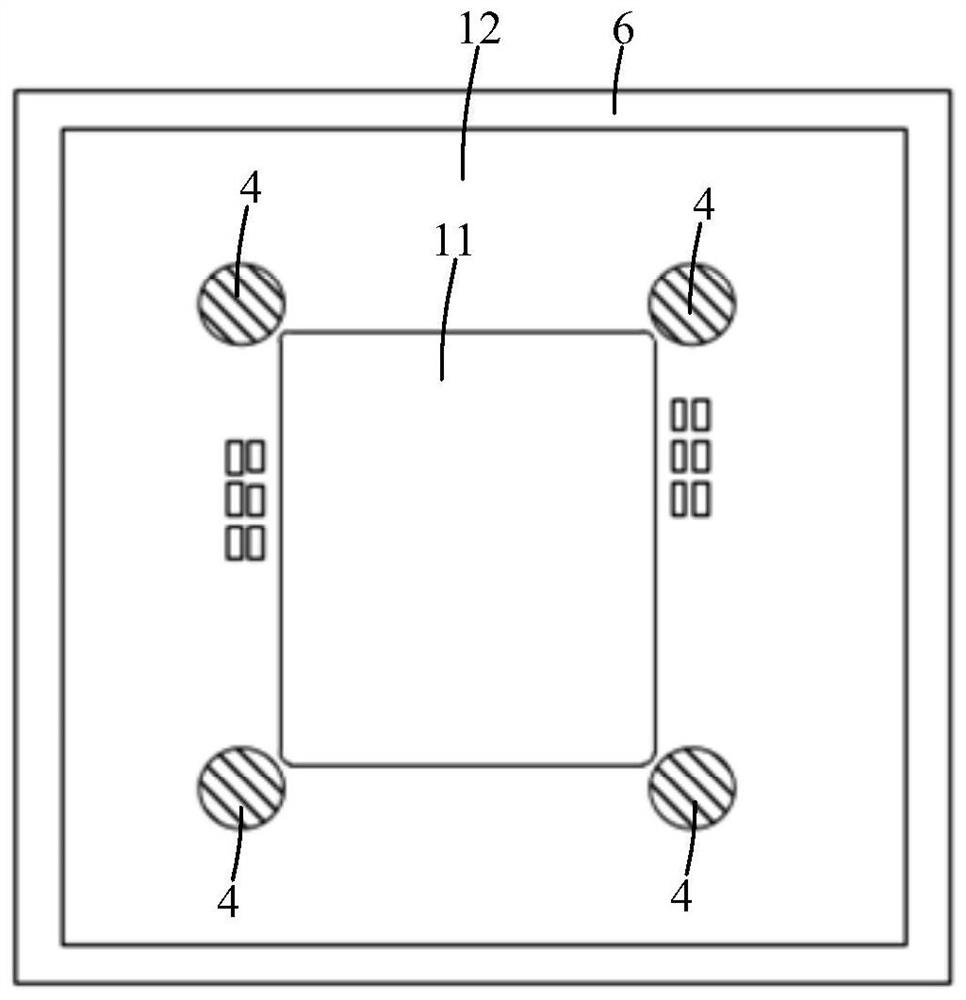

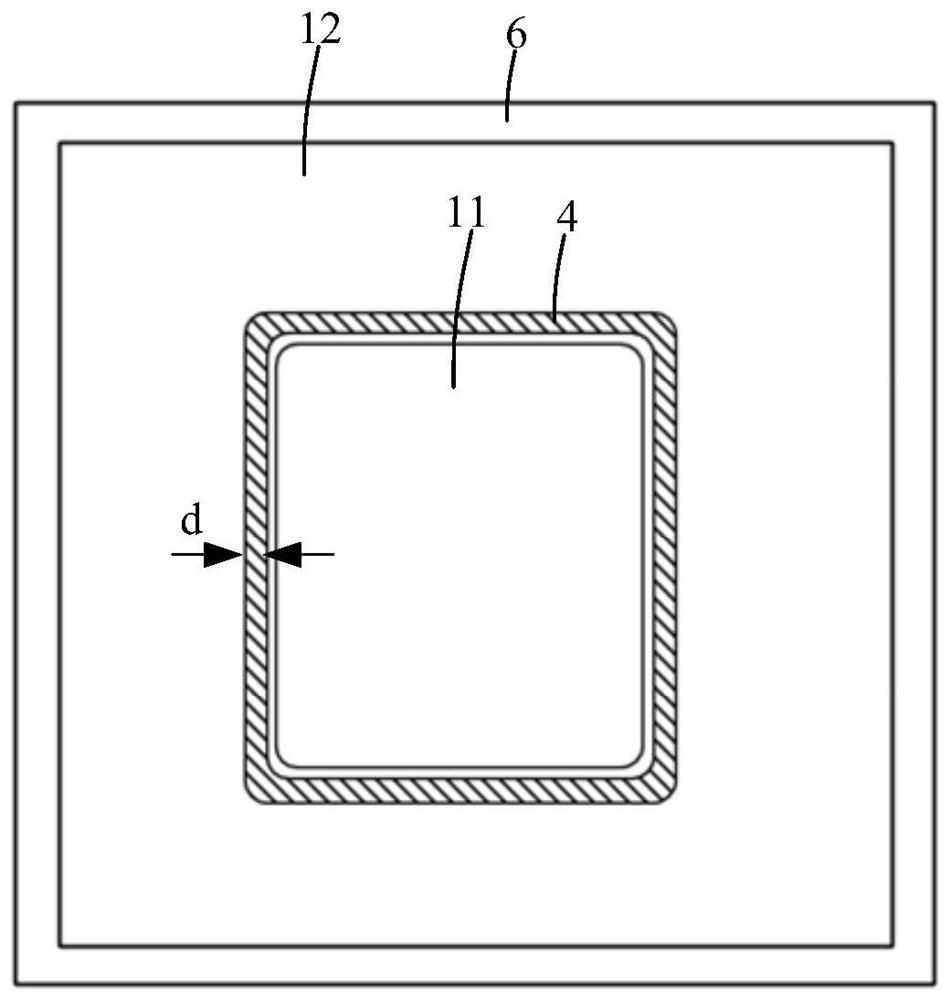

[0057] The embodiment of the present application relates to a single board, which may be a main control board, a service board, or an interface board of a computing device, such as figure 1 As shown, the single board includes a chip 1 and a circuit board 3, wherein: the chip 1 includes a chip device 11 and a chip substrate 12, the chip device 11 is located on the chip substrate 12, and the chip substrate 12 is located on the circuit board 3; There is a supporting member 4 around the chip device 11 , the first end of the supporting member 4 is used to attach to the heat sink 2 , and the second end of the supporting member 4 is attached to the chip substrate 12 .

[0058] In some embodiments, the single board may not include the radiator 2 , or may include the radiator 2 . For example, when manufacturing a single board, the heat sink 2 may be integrated on the single board, for example, the heat sink 2 is placed on the support member 4 and the chip device 11 . For another examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com