Miniature touch switch assembling machine

A light touch switch and assembly machine technology, which is applied in assembly machines, electric switches, metal processing equipment, etc., can solve problems such as low production efficiency, difficult quality assurance, and inability to meet production development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be described in further detail below in conjunction with the accompanying drawings.

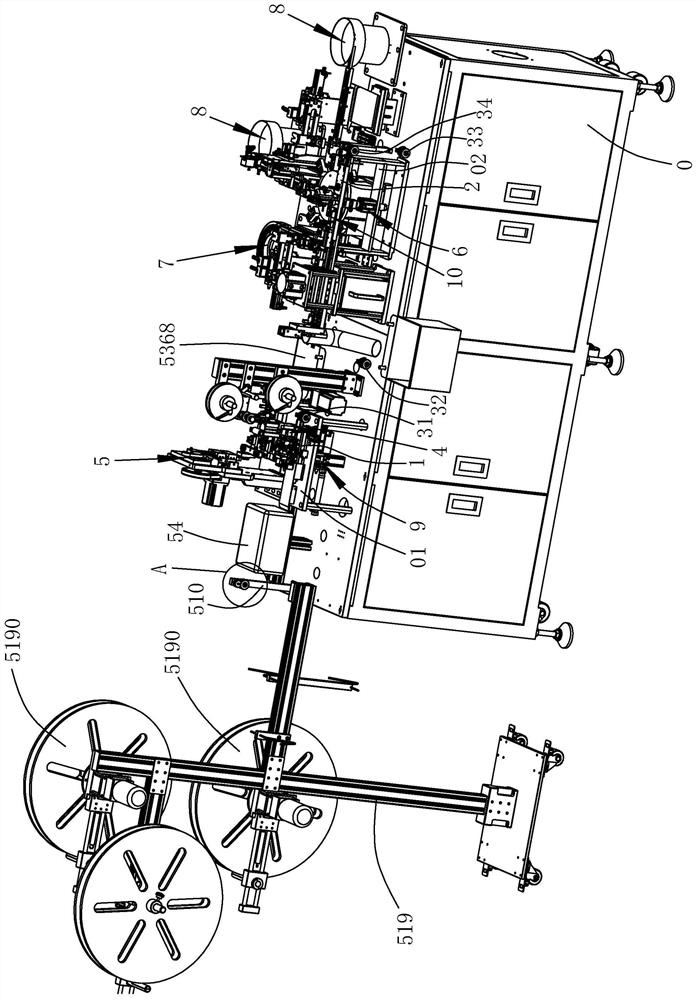

[0083] refer to figure 1 , is a miniature tact switch assembly machine disclosed in the present invention, including a cabinet 0 and a first guide rail 1, a second guide rail 2 and a base strip turning wheel set 3 arranged on the side of the cabinet 0, under the first guide rail 1 A support table 01 is provided, and a support frame 02 is provided below the second guide rail 2 , which is located at one end of the first guide rail 1 and is parallel to the first guide rail 1 .

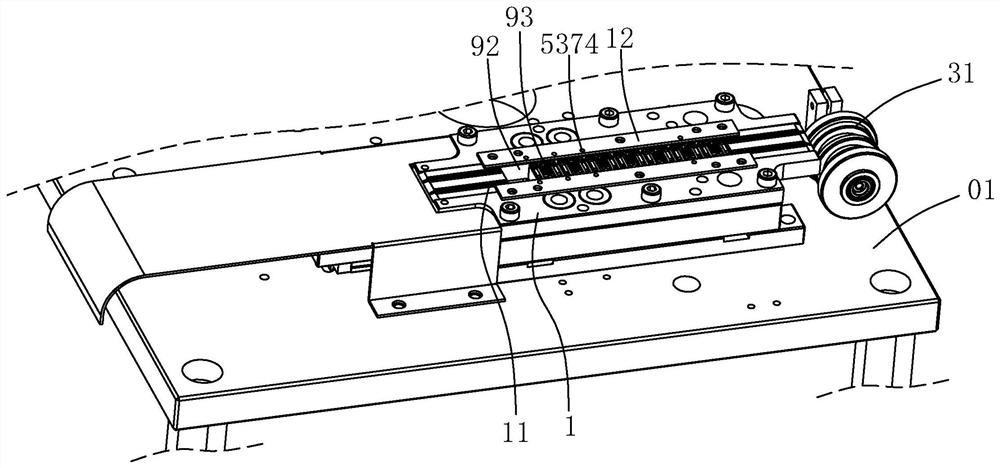

[0084] refer to figure 2 On the upper side of the first guide rail 1 along the length direction of the first guide rail 1, a first passage groove 11 is provided, and first pressing pieces 12 are arranged on both sides of the first passage groove 11, and one side of the first pressing piece 12 is connected to the first guide rail 1. Bolt connection, the other side extends above the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com