Fixing device for plastic pipe production

A technology for fixing devices and plastic pipes, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of cumbersome fixing process and waste of time, and achieve the effects of faster fixing efficiency, convenient use and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

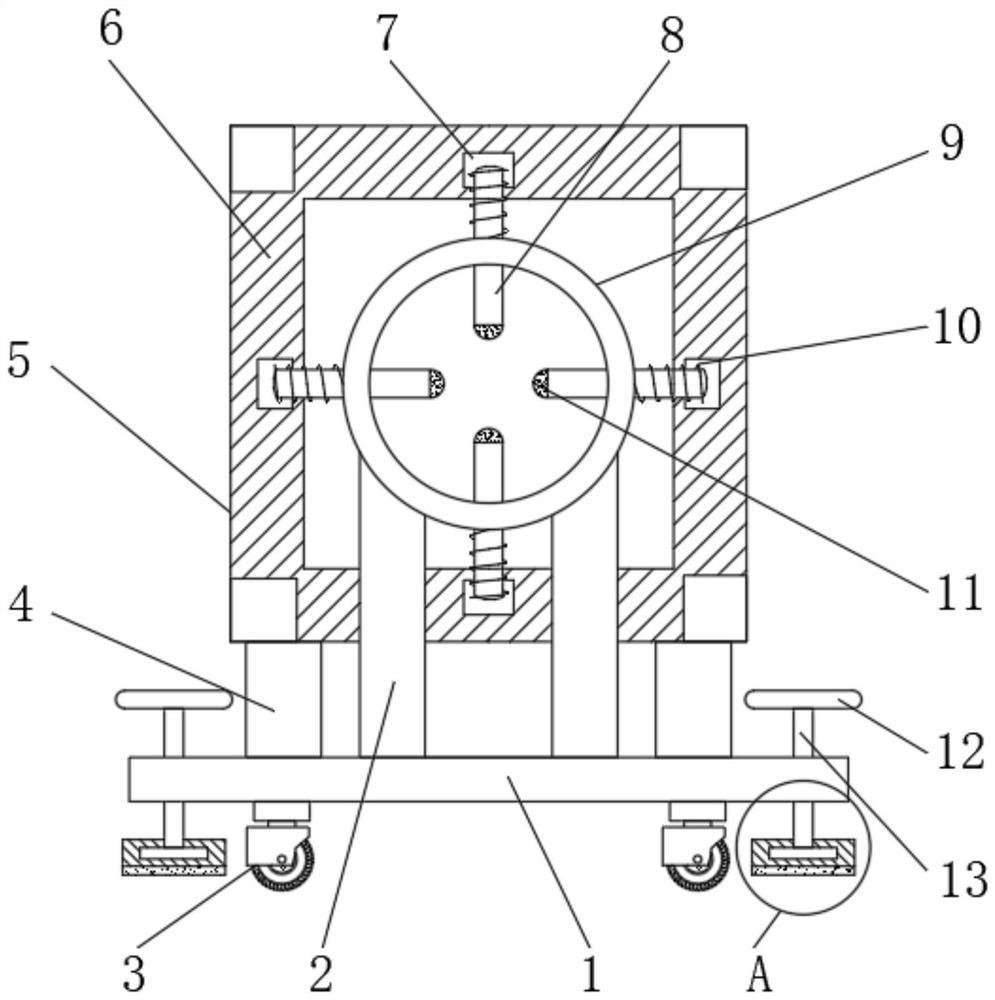

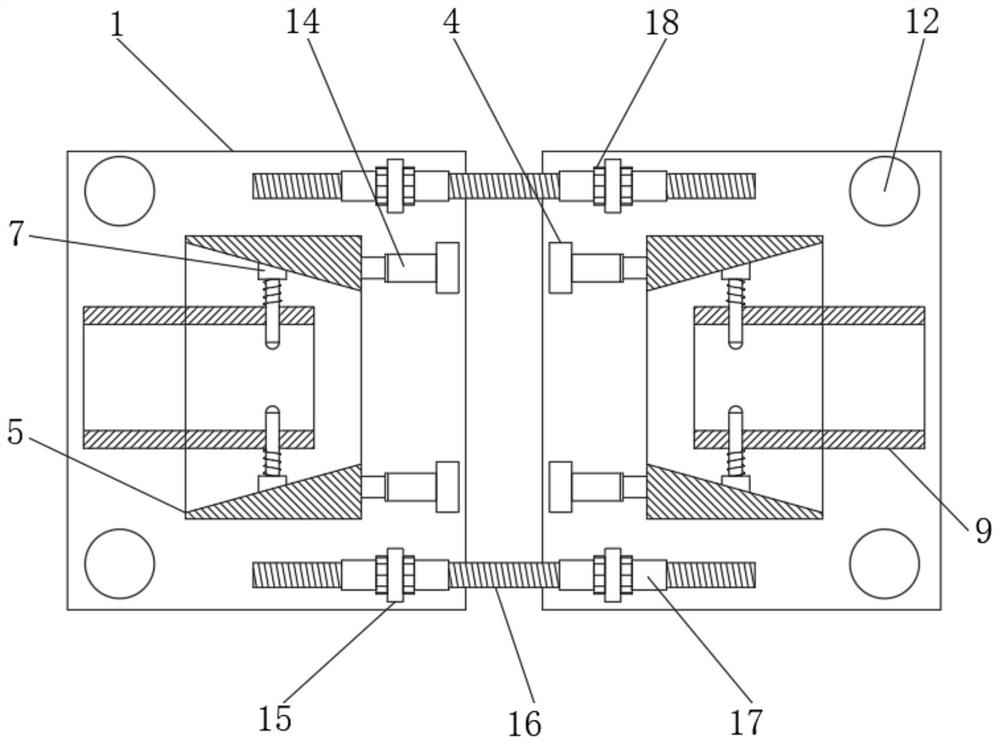

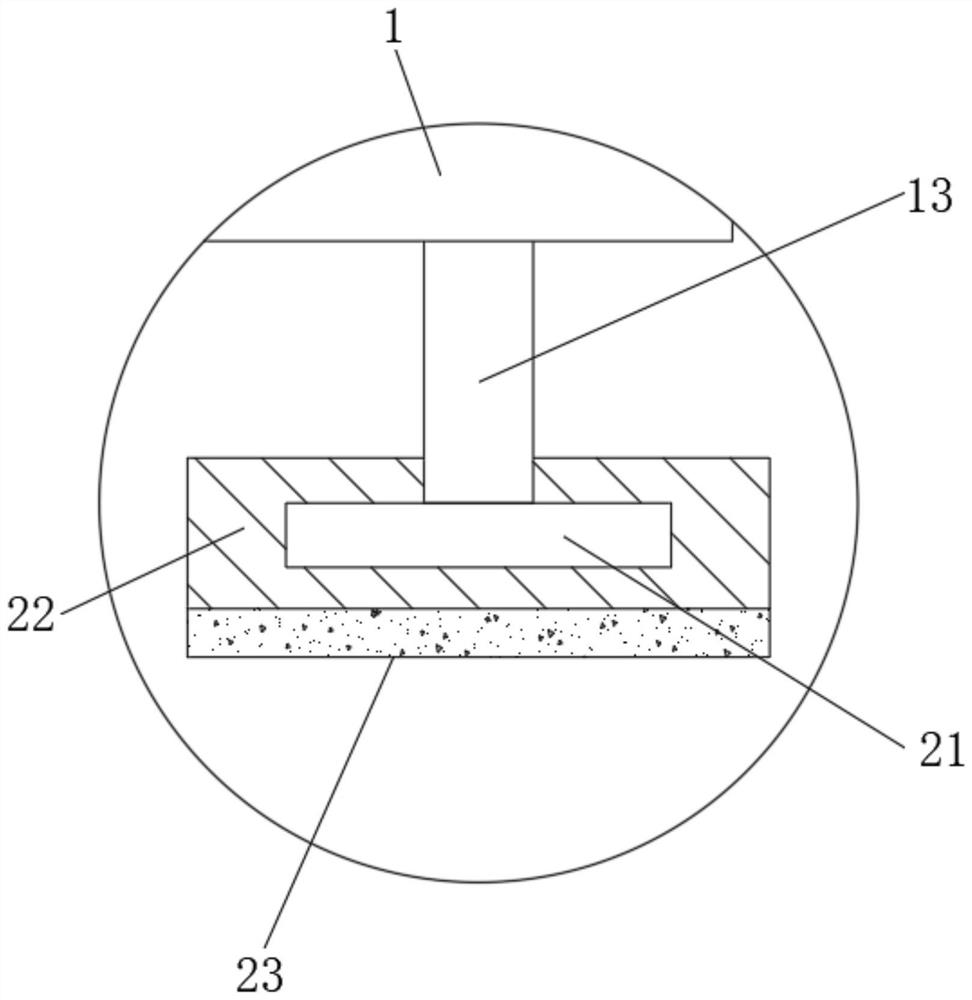

[0031] refer to Figure 1-4 , a fixing device for plastic pipe production, comprising a base plate 1, a movable frame 5 and a fixed cylinder 9, the top outer wall of the base plate 1 is welded with a support column 2, and the top outer wall of the support column 2 is welded to the bottom outer wall of the fixed cylinder 9, the base plate The top outer wall of 1 is welded with a fixed plate 4, and one side outer wall of the fixed plate 4 is connected with a hydraulic cylinder 14 by bolts, one end of the piston of the hydraulic cylinder 14 is connected with the outer wall of the movable frame 5 side by bolts, and the surrounding inner walls of the movable frame 5 are There is a chute 6, and the outer wall of the fixed cylinder 9 is provided with sliding holes, and the inner wall of the sliding hole is slidably connected with a slider 8, and the outer wall of one end of the slider 8 is welded with a slider 7, and the section of the slider 7 is a right angle. trapezoidal, the oute...

Embodiment 2

[0035] refer to Figure 5, a fixing device for plastic pipe production. Compared with Embodiment 1, this embodiment also includes a rubber block 11 with a cavity 19 inside, and a pressure sensor 20 inside the cavity 19. The pressure sensor 20 The signal output terminal is connected with the controller through the signal line, and the controller is connected with the switch through the wire.

[0036] Working principle: When in use, when the rubber block 11 is in contact with the pipe, the cavity 19 in the rubber block 11 is compressed, so that the pressure sensor 20 in the cavity 19 can detect the pressure value of the pipe, when it reaches a certain pressure value Just can send signal to controller, controller sends control signal to the switch of hydraulic cylinder 14, makes hydraulic cylinder 14 stop working, effectively avoids that the situation that plastic pipeline is crushed occurs, and use effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com