Touch control chip simulation pressing test jig

A technology for testing jigs and touch chips, applied in electronic circuit testing, measuring electricity, measuring devices, etc., can solve the problems of chip damage, waste of time, low test efficiency, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

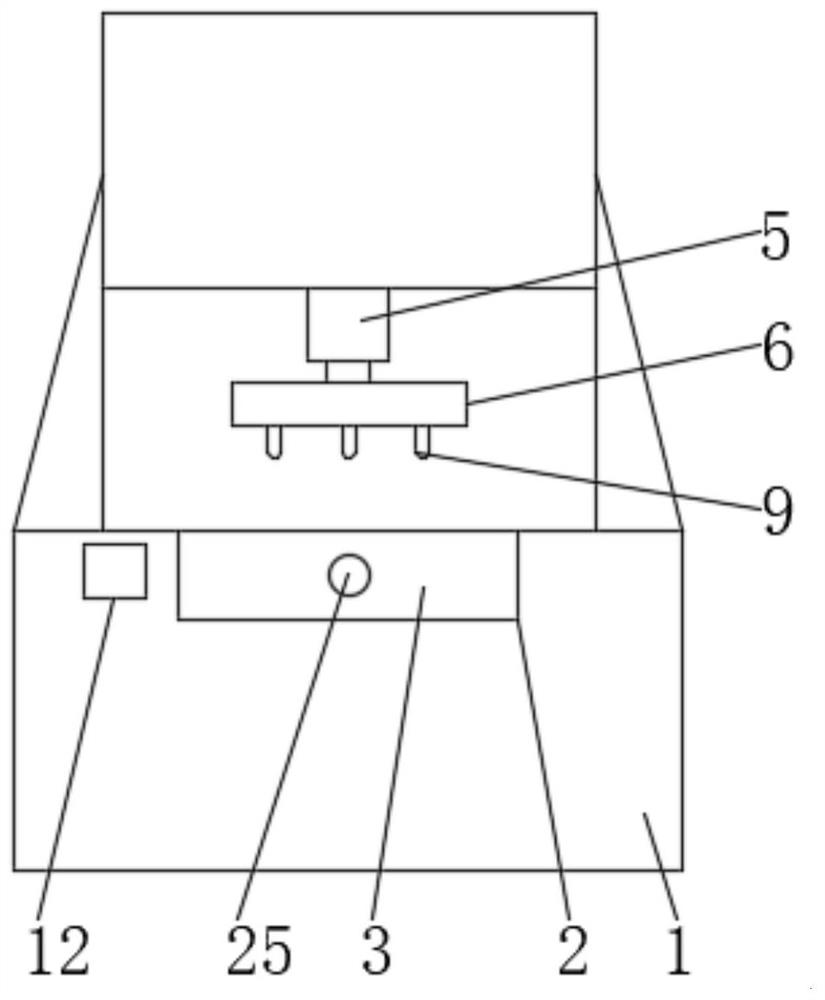

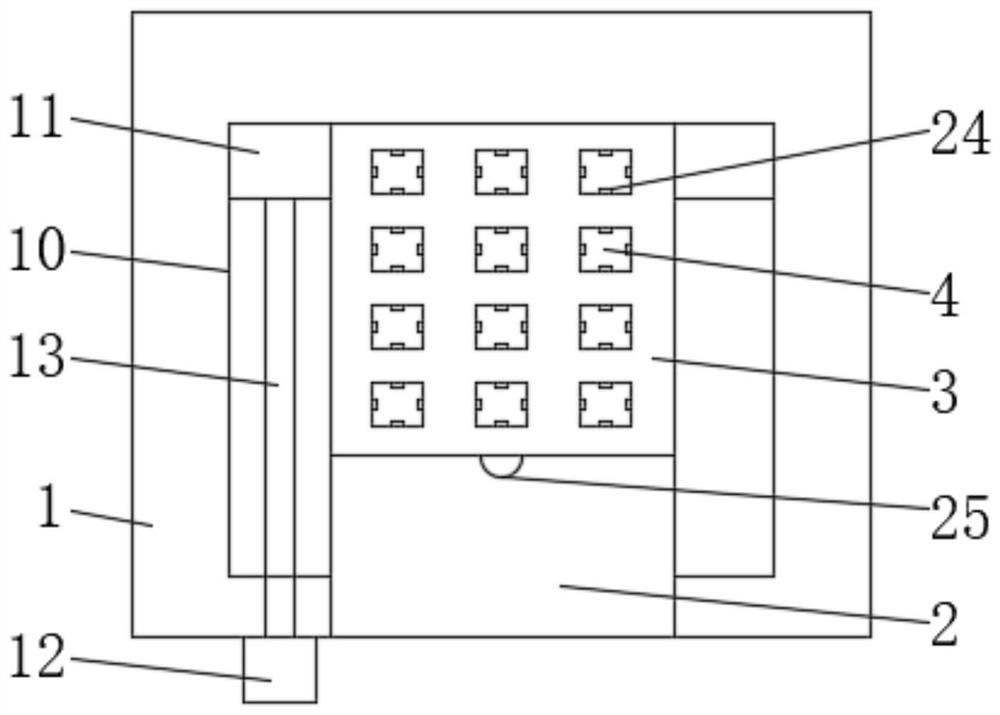

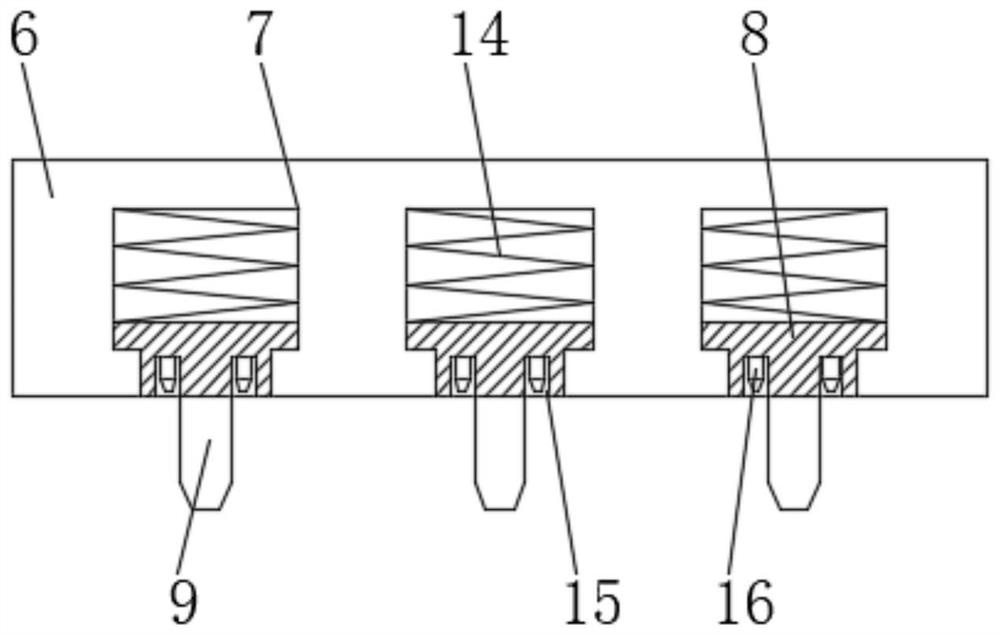

[0021] see figure 1 , figure 2 , image 3 , touch chip simulation press test fixture, including test machine body 1, a chute 2 is provided on the machine table of the test machine body 1, a plate 3 is set inside the chute 2, and a chip groove 4 is provided on the plate 3 , the testing machine body 1 is equipped with a cylinder 5 through screws, and the lower end of the cylinder 5 is equipped with a lifting plate 6 through screws. The probe 9 is mounted by screws.

[0022] see figure 1 , figure 2 , the number of chip slots 4 and probes 9 is equal, and the positions correspond to each other, the chip slots 4 and probes 9 are evenly distributed on the plate 3 and the lifting plate 6 respectively, by controlling multiple probes 9 to multiple chip slots 4 The internal chip is tested, which can improve the efficiency of the test.

[0023] see figure 2 , both sides of the inner wall of the chute 2 are provided with limit slides 10, and both sides of the plate 3 are installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com