Cultivation rotation working part with bionic geometric structure

A technology of rotating work and geometric structure, applied in the field of farming rotating working parts and farming machinery design, can solve the problems of increasing energy consumption, machinery can not work, increasing working resistance, etc., achieving low energy consumption, low soil cutting resistance, The effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

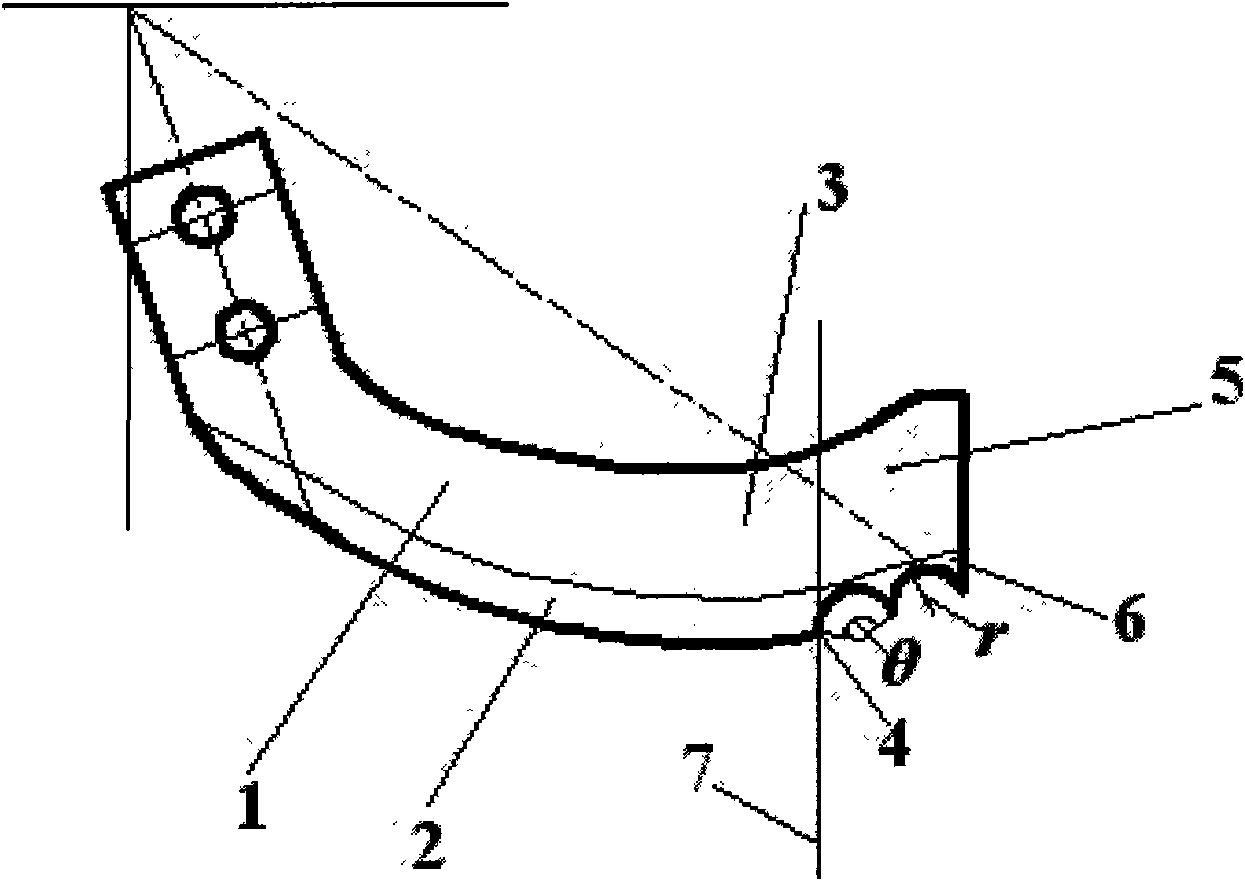

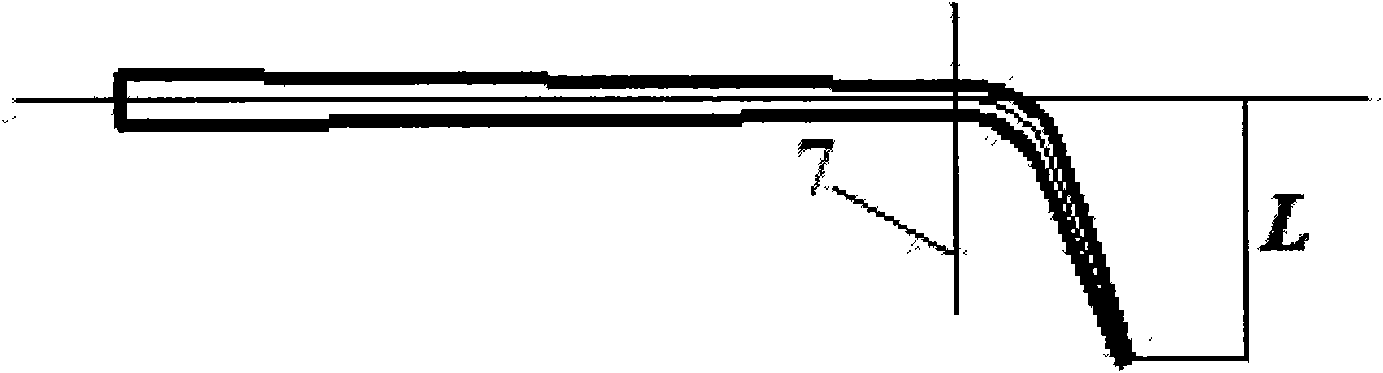

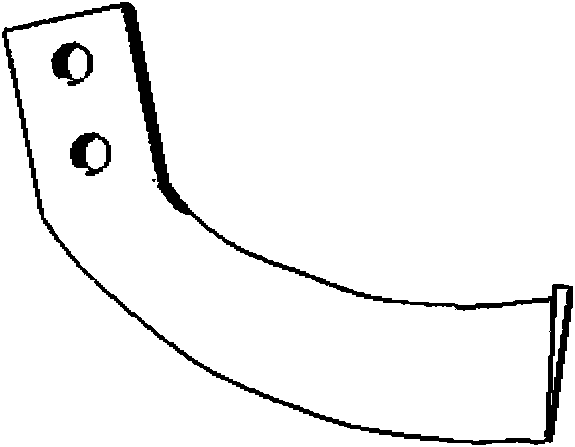

Embodiment 1

[0031] In this example, the specific structure of the new farming rotary working part with bionic geometry is given by image 3 and Figure 4 show. The structural feature of the novel tillage rotating part of this example is: the tangential section of the blade is triangular when seen from the side, which is different from the rectangular section of the traditional blade. There is a bionic arc cutting edge distributed on the cutting edge of the blade, the directions are facing inward and outward respectively, the chord length is fixed to the blade width L, which is 60mm, and the center angle of the round edge can be adjusted, corresponding to the change of the center angle or half circle As the (straight) diameter changes, the size of the bionic cutting edge also changes.

Embodiment 2

[0033] In this example, the specific structure of the new farming rotary working part with bionic geometry is given by Figure 5 and Figure 6 show. The new type of farming rotary working part with bionic geometric shape described in this example is different from Example 1 in that the tangential side view of the blade in this example is triangular, and the tangent edge is evenly distributed with 2 bionic arc cutting edges facing inward (outward). , the chord length is L / 2, that is, 30mm, if the corresponding center angle or the semi-(straight) diameter of the arc changes, the size of the two bionic cutting edges will also change accordingly.

Embodiment 3

[0035] In this example, the specific structure of the new farming rotary working part with bionic geometry is given by Figure 7 and Figure 8 show. The new farming rotary working part with bionic geometry described in this example differs from Example 1 and Example 2 in that the tangential side view of the blade in this example is triangular, and the tangential edges are evenly distributed with 3 bionic inwards (outwards) The chord length of the arc cutting edge is L / 3, that is, 20mm. The size of the bionic cutting edge is determined by the corresponding central angle or semi (diameter) diameter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com