Bionic rotary-cutting and stubble-breaking blade

A technology of blade and stubble, applied in application, tillage equipment, crop processor, etc., can solve problems such as low operation efficiency, and achieve the effect of low soil cutting resistance, easy popularization and application, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

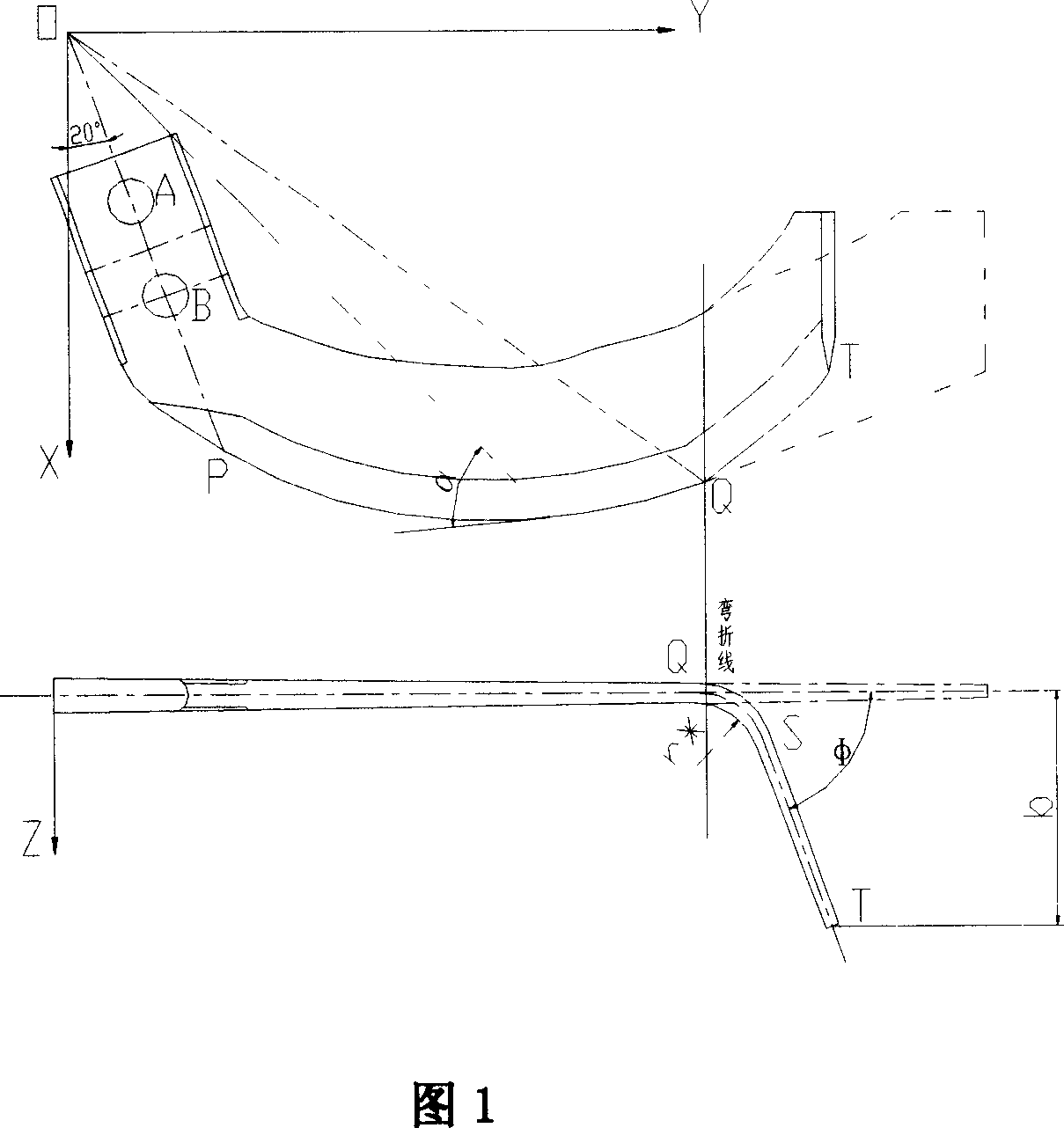

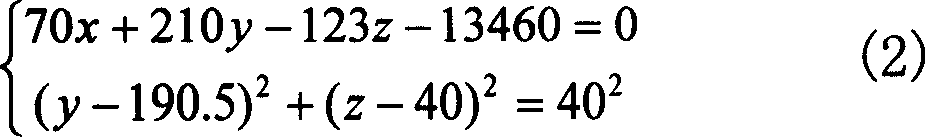

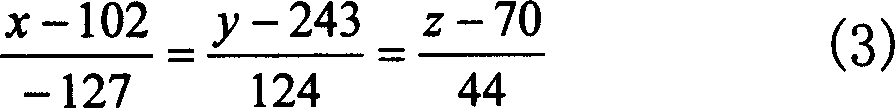

[0013] Fig. 1 shows the structure of the general blade of the bionic rotary tillage of the present invention. In Fig. 1, the coordinate origin O is the intersection point of the side section of the blade and the center line Z of the cutter roller axis, and the upper part of Fig. 1 represents the general blade Schematic diagram of the structure in the XYZ coordinate system, wherein the dotted line part is the projection of the tangent surface of the universal blade in the XOY plane, and the lower part of Fig. 1 represents the projection of the universal blade in the YOZ plane. In the XYZ Cartesian coordinate system, the Z axis is the center line of the cutter roller axis, the side cut surface is in the XOY plane, but the tangent surface is not in the XOY plane, and it bends toward the Z axis along the bending line, as shown in the lower part of Figure 1 . The transition face (where the QS surface is located) is located between the side cut face and the tangent face. The two po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com