Mechanical equipment visual interaction and equipment state monitoring system and method based on augmented reality

A technology of augmented reality and mechanical equipment, applied in the direction of image data processing, instruments, etc., can solve problems such as backwardness, backward design methods, and failure to apply interactive motion simulation and product analysis technology, so as to improve operation quality and efficiency, Reduce the effect of monitoring wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

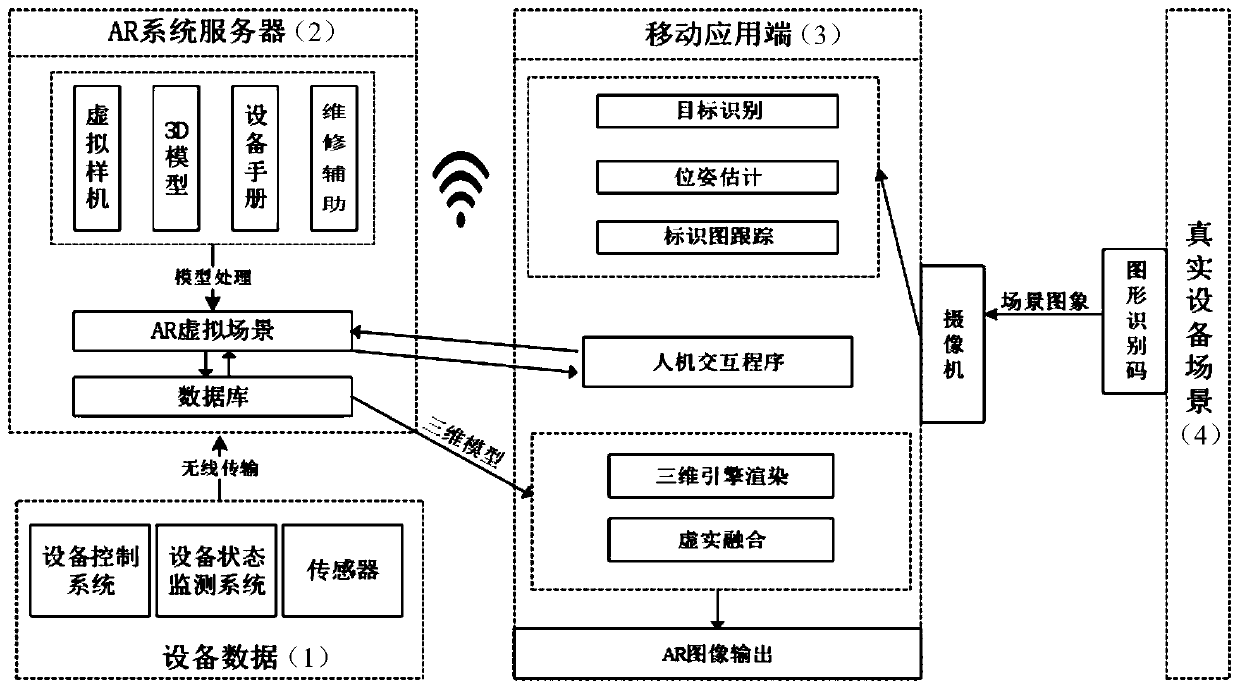

[0021] figure 1 A mechanical equipment visual interaction and equipment status monitoring system based on augmented reality technology is shown, which is characterized in that it consists of four modules, namely equipment data module, AR system server module, mobile application terminal module and real equipment scene module, The equipment data module collects and summarizes the state parameter data of mechanical equipment, wirelessly transmits it to the AR system server module, and performs model processing and data superposition in the AR system server module, constructs an AR virtual scene, and transmits the AR virtual scene through the network according to the requirements of the mobile application module The command sends the corresponding scene content, and the camera on the mobile application side captures the scene image of the real device scene module, recognizes the graphic identification code, estimates the pose and tracks the logo map, provides visual human-computer...

Embodiment 2

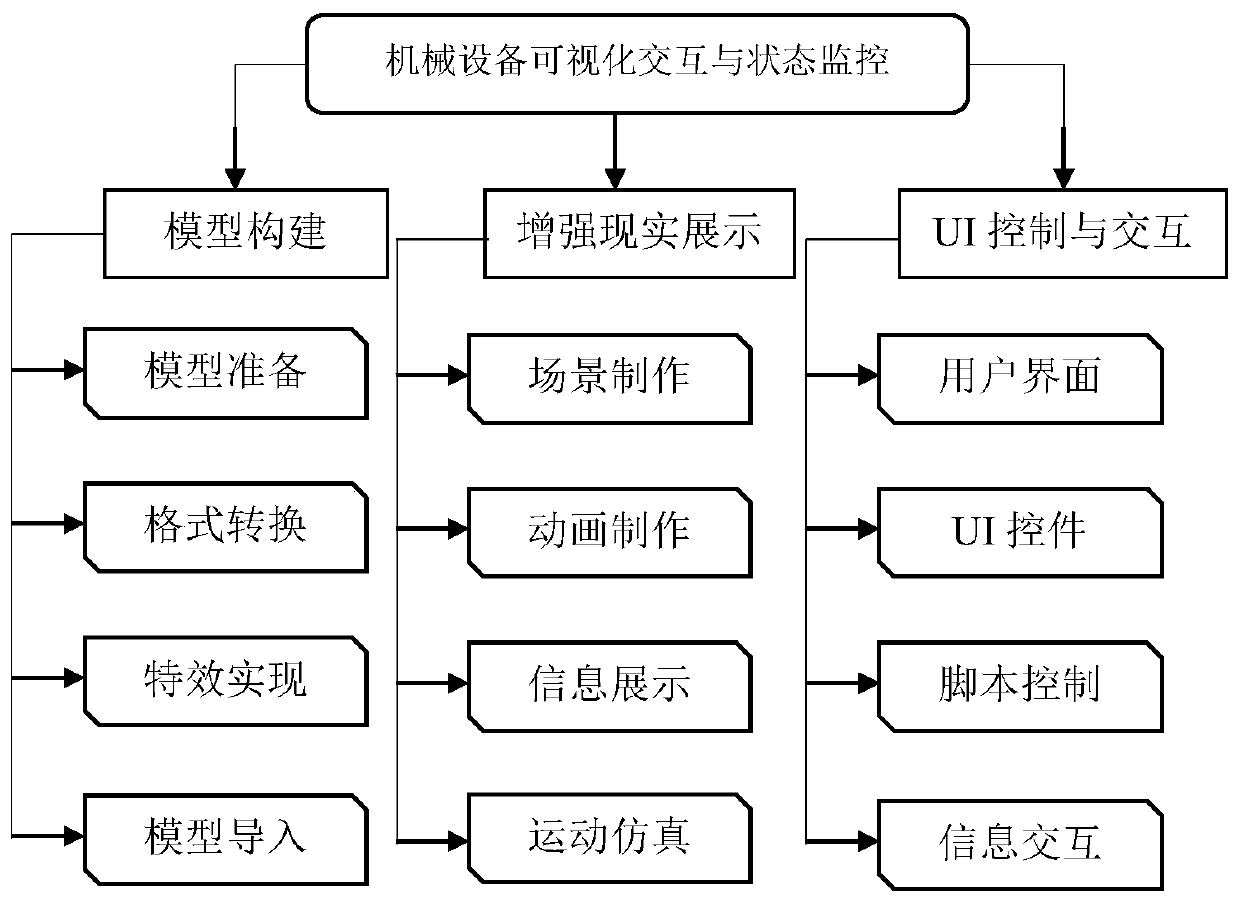

[0027] figure 2 The design method of visual interaction of mechanical equipment and equipment status monitoring based on augmented reality is divided into three parts: model construction, augmented reality display, UI control and interaction.

[0028] 1) Model construction

[0029] The model construction part is the basic part to realize the overall plan. Before development, it is first necessary to have all the mechanical 3D models required for development, including 3D model establishment and processing, animation production and production of product motion simulation actions, through the combination of multiple software , and finally converted to a compatible file format supported by Unity 3D and ThingWorx Studio and imported into it, and then use the development engine to create scenes and construct actions and information parts.

[0030] 2) Augmented reality display

[0031] The enhanced display display part is the core part. After completing a series of preparations f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com