Three-dimensional attitude display and remote automatic control system of excavator

An automatic control system and three-dimensional attitude technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of poor software versatility, coordination of measurement and control systems, and difficult engineering implementation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

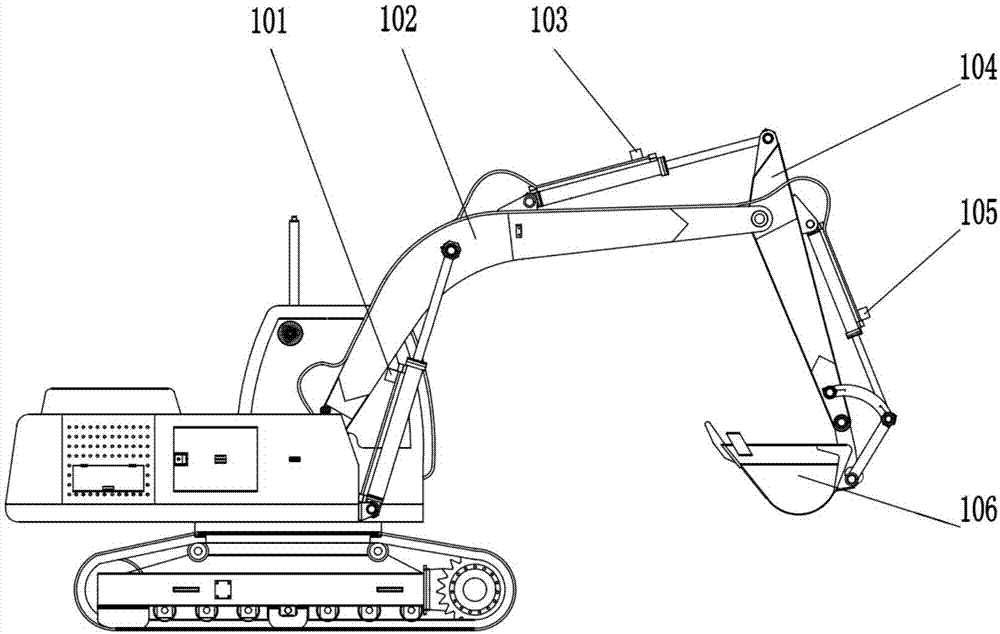

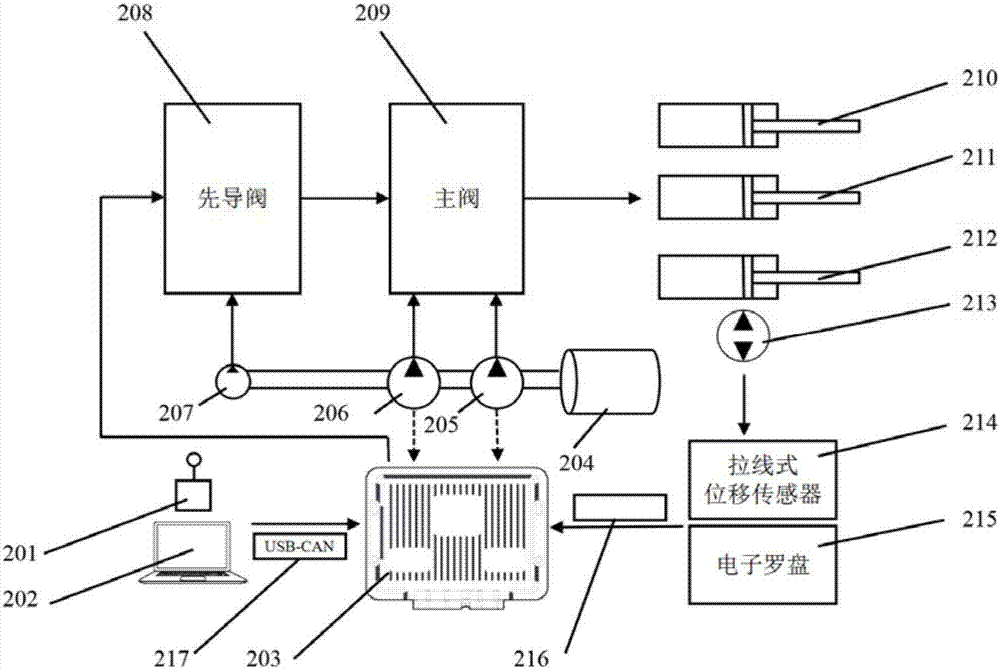

[0079] Such as figure 1 and figure 2 As shown, the three-dimensional posture display and its remote automatic control system of the present invention include an excavator operation module, a data acquisition module, a computer 202 (the computer includes a real-time trajectory calculation module), a trajectory control module, an operation information monitoring module, a data storage module and a three-dimensional visualization module,

[0080] The excavator operation module includes an oil control loop composed of an operating handle 201, a computer 202, a DSP controller 203, an electro-hydraulic proportional valve 208 and a multi-way valve 209; an oil supply circuit composed of a pilot pump 207, a front pump 205 and a rear pump 206 Components: boom hydraulic cylinder 210, stick hydraulic cylinder 211, bucket hydraulic cylinder 212 and swing motor 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com